Coagulation-Flocculation

Executive Summary

Coagulation-flocculation is a chemical water treatment technique typically applied prior to sedimentation and filtration (e.g. rapid sand filtration) to enhance the ability of a treatment process to remove particles. Coagulation is a process used to neutralise charges and form a gelatinous mass to trap (or bridge) particles thus forming a mass large enough to settle or be trapped in the filter. Flocculation is gentle stirring or agitation to encourage the particles thus formed to agglomerate into masses large enough to settle or be filtered from solution.

| In | Out |

|---|---|

|

Freshwater |

Treated Water |

Introduction

Dissolved and suspended particles are present in most of natural waters. These suspended materials mostly arise from land erosion, the dissolution of minerals and the decay of vegetation and from several domestic and industrial waste discharges. Such material may include suspended, dissolved organic and/or inorganic matter, as well as several biological organisms, such as bacteria, algae or viruses. This material has to be removed, as it causes deterioration of water quality by reducing the clarity (e.g. causing turbidity or colour), and eventually carrying pathogenic organisms or toxic compounds, adsorbed on their surfaces (TZOUPANOS and ZOUBOULIS 2008).

To separate the dissolved and suspended particles from the water coagulation and flocculation processes are used. Coagulation and flocculation is relatively simple and cost-effective, provided that chemicals are available and dosage is adapted to the water composition. Regardless of the nature of the treated water and the overall applied treatment scheme, coagulation-flocculation is usually included, either as pre-treatment (e.g. before rapid sand filtration) or as post-treatment step after sedimentation (see also centralised water purification plants).

Most solids suspended in water possess a negative charge; they consequently repel each other. This repulsion prevents the particles from agglomerating, causing them to remain in suspension. Coagulation and flocculation occur in successive steps intended to overcome the forces stabilising the suspended particles, allowing particle collision and growth of flocs, which then can be settled and removed (by sedimentation) or filtered out of the water. Coagulation-Flocculation is also a common process to treat industrial and domestic wastewater in order to remove suspended particles from the water.

Coagulation principles

(Adapted from MRWA 2003)

Coagulation destabilises the particles’ charges. Coagulants with charges opposite to those of the suspended solids are added to the water to neutralise the negative charges on dispersed non-settable solids such as clay and organic substances.

Once the charge is neutralised, the small-suspended particles are capable of sticking together. The slightly larger particles formed through this process are called microflocs and are still too small to be visible to the naked eye. A high-energy, rapid-mix to properly disperse the coagulant and promote particle collisions is needed to achieve good coagulation and formation of the microflocs. Over-mixing does not affect coagulation, but insufficient mixing will leave this step incomplete. Proper contact time in the rapid-mix chamber is typically 1 to 3 minutes.

Flocculation

(Adapted from MRWA 2003)

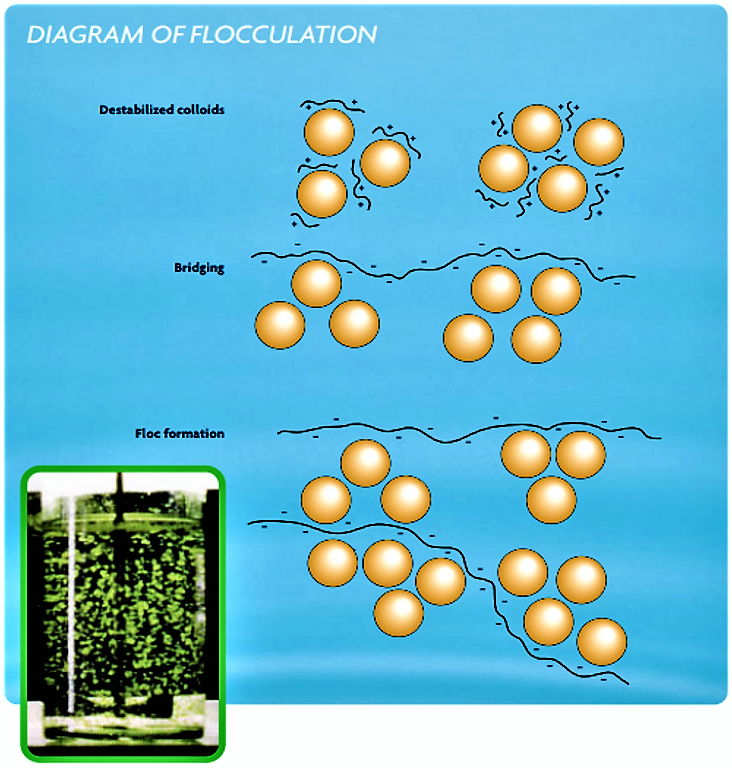

Following coagulation, flocculation, a gentle mixing stage, increases the particle size from submicroscopic microfloc to visible suspended particles.

The microflocs are brought into contact with each other through the process of slow mixing. Collisions of the microfloc particles cause them to bond to produce larger, visible flocs. The floc size continues to build through additional collisions and interaction with inorganic polymers formed by the coagulant or with organic polymers added. Macroflocs are formed. High molecular weight polymers, called coagulant aids, may be added during this step to help bridge, bind, and strengthen the floc, add weight, and increase settling rate. Once the floc has reached its optimum size and strength, the water is ready for the separation process (sedimentation, floatation or filtration). Design contact times for flocculation range from 15 or 20 minutes to an hour or more.

Coagulation flocculation separation

(Adapted from SNF FLOERGER 2003)

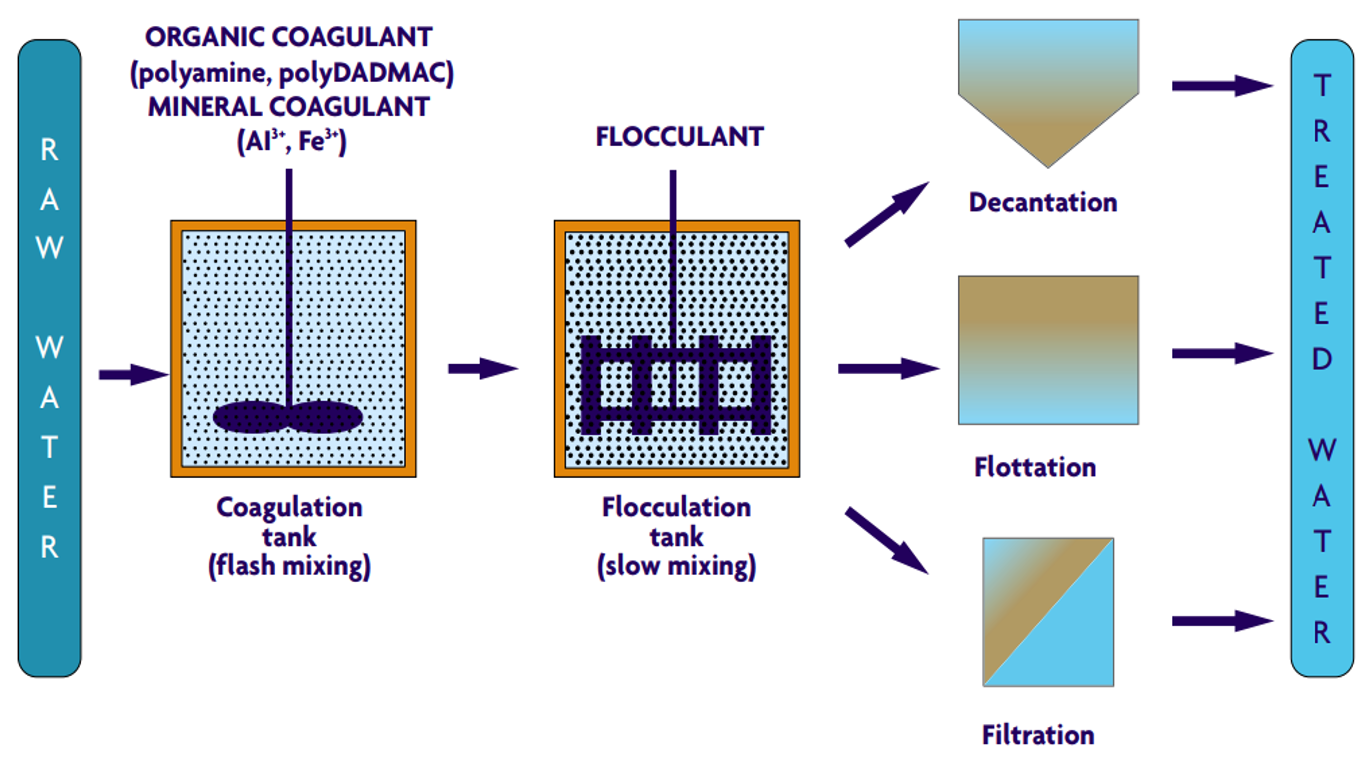

In water treatment, coagulation and flocculation are practically always applied subsequently before a physical separation. TheCoagulation-Flocculationprocess consists of the following steps:

- Coagulation-flocculation: The use of chemical reagents to destabilise and increase the size of the particles; mixing; increasing of flog size,

- A physical separation of the solids from the liquid phase. This separation is usually achieved by sedimentation (decantation), flotation or filtration.

The common reagents are: mineral and/or organic coagulants (typically iron and aluminium salt, organic polymers), flocculation additives (activated silica, talcum, activated carbon…), anionic or cationic flocculants andpHcontrol reagents such as acids or bases. Certain heavy metal chelating agents can also be added during the coagulation step.

Jar test

(Adapted from TRIPATHY and DE 2006)

The jar test is used to identify the most adapted mix of chemical compounds and concentrations for coagulation-flocculation. It is a batch test consisting of using several identical jars containing the same volume and concentration of feed, which are charged simultaneously with six different doses of a potentially effective coagulant. The six jars can be stirred simultaneously at known speeds. The treated feed samples are mixed rapidly and then slowly and then allowed to settle. These three stages are an approximation of the sequences based on the large-scale plants of rapid mix, coagulation flocculation and settling basins. At the end of the settling period, test samples are drawn from the jars and turbidity of supernatant liquid is measured. A plot of turbidity against coagulant dose gives an indication of the optimum dosage (i.e. the minimum amount required to give acceptable clarification). The criteria thus obtained from a bench jar test are the quality of resultant floc and the clarity of the supernatant liquid after settling. The design of the full-scale plant process is then done based on the bench-scale selection of chemicals and their concentrations.

Unfortunately, the jar test suffers from a number of disadvantages, despite its widespread application. It is a batch test, which can be very time-consuming. And the results obtained from a series of jar tests might not correspond to the results obtained on a full-scale plant.

Operation and maintenance

(Adapted from WHO 1996)

The operation of coagulators, flocculators and clarifiers requires trained operators. Maintenance work should be undertaken regularly. The key aspects of operation and maintenance of coagulators, flocculators and clarifiers are:

- Chemical stock: There should be a good stock (at least sufficient for one month of operation).

- Dosing control: Correct dosing of coagulant chemicals is very important for efficient and effective removal of suspended solids. Samples of raw water should be taken regularly, and tested with a range of coagulant concentrations to determine the optimum dose rate of coagulant. The results should be used to adjust the coagulant dose.

- Rapid mixing of the water and coagulant chemicals at the point where the chemicals are added is essential.

- Flocculation should be achieved by gentle mixing so as to maximise the number of collisions between suspended particles and flocs, without breaking the flocs up through rapid mixing.

- Plant layout: The flocculator and clarifiers should be located close to one another and water should flow slowly between them so as to not break up the flocs.

During the course of coagulation-flocculation treatment, a substantial amount of sludge coming from the settling process is generated. This sludge can be reused as fertiliser for agriculture when no toxic compounds are present. In the presence of toxic sludge the solid waste has to be treated or disposed of in an environmentally proper manner.

At a glance

|

Working Principle |

Suspended particles are destabilised by addition of a clarifying agent leading to the neutralisation of their charges. Particles thus agglomerate (flocs formation) and are able to decant. |

|

Capacity/adequacy |

Relatively simple technology |

|

Performance |

High efficiency in removing charged suspended and dissolved particles |

|

Costs |

Relatively low cost |

|

Self-help compatibility |

Skilled operators required |

|

O&M |

Continuous consumption of chemicals and electricity |

|

Reliability |

Reliable if operating conditions are optimised taking into account wastewater content |

|

Main strength |

Removes solids and improves filtration |

|

Main weakness |

Continuous input of chemicals required |

Coagulation-flocculation is a conventional pre-treatment method (typically in combination with sedimentation] and rapid sand filtration) used to separate the suspended and dissolved compounds (turbidity) from the water in (semi-)centralised drinking water treatment plants. Many charged species such as suspended mineral, organics, pathogens, and dissolved species such as metal ions, phosphates, fluoride, and radionuclides can be separated by these processes.

Chemicals reactants (flocculants and coagulants) concentration must be adjusted properly to the exact composition of the water. The operation of coagulators, flocculators and clarifiers requires trained operators. Maintenance work should be undertaken regularly to guarantee an efficient treatment.

Coagulation-flocculation is also often used to remove suspended solids in domestic and industrial wastewater treatment plants.

-

Pbtc Scale InhibitorPBTC: A Scale Protector for Industrial Water TreatmentNewsAug.05,2025

-

Organic Phosphonate: An Efficient Defender in the Field of Scale InhibitionNewsAug.05,2025

-

Hydrolyzed Polymaleic Anhydride: Green Pioneer in Scale Inhibition FieldNewsAug.05,2025

-

PAPEMP Polyamino Polyether Methylene Phosphonic Acid For SaleNewsAug.05,2025

-

Flocculant Water Treatment: A Pioneer in Purification in the Field of Water TreatmentNewsAug.05,2025

-

Benzyl Isothiazolinone: An Efficient and Broad-Spectrum Antibacterial Protective GuardNewsAug.05,2025