scale inhibitor

Understanding Scale Inhibitors Their Role and Importance in Industrial Applications

In various industrial processes, especially those involving water, the formation of scale can pose significant challenges. Scale refers to the buildup of mineral deposits, primarily composed of calcium carbonate, gypsum, and other inorganic substances that precipitate out of solution. This buildup can clog pipes, reduce heat transfer efficiency, and ultimately lead to costly downtime and maintenance. To combat these issues, industries often employ scale inhibitors. This article delves into the mechanisms of scale inhibitors, their benefits, and their applications across different sectors.

What are Scale Inhibitors?

Scale inhibitors are chemical agents designed to prevent the formation of scale in water systems. They work by modifying the crystallization process of mineral salts, thereby keeping them soluble in water and preventing them from precipitating out and forming hard deposits. Typically, these inhibitors integrate into various processes, including cooling systems, boilers, and oil extraction facilities.

Mechanisms of Action

The effectiveness of scale inhibitors lies in their chemical structure and interactions with scale-forming ions. There are several mechanisms through which these inhibitors operate

1. Threshold Inhibition Some scale inhibitors prevent crystal growth at low concentrations. They establish a threshold where scale formation is significantly reduced, allowing minerals to remain in solution longer.

2. Crystal Modifiers Certain inhibitors act as modifiers by altering the size, shape, and growth pattern of crystals that may form. This change makes it easier for these crystals to remain suspended in the water rather than aggregating and depositing onto surfaces.

3. Dispersion Some inhibitors work by preventing the agglomeration of scale particles. By keeping these particles dispersed in the water, they avoid forming larger deposits that could lead to blockages and other inefficiencies.

Types of Scale Inhibitors

There are various types of scale inhibitors, and their effectiveness can depend on the specific application and the water chemistry involved. Common categories include

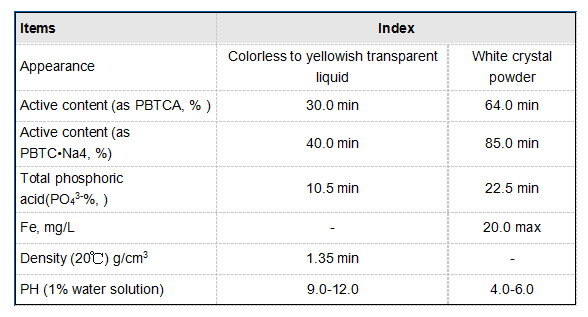

- Phosphonates Compounds that are particularly effective against calcium carbonate and calcium sulfate scaling. - Polyacrylates These are widely used in cooling water systems and are known for their ability to disperse precipitated scales. - Glutaraldehyde Often used in water treatment, glutaraldehyde not only helps inhibit scale formation but also serves as a biocide.

Industry Applications

scale inhibitor

Scale inhibitors find extensive use across multiple industries, including

1. Power Generation In cooling towers and steam boilers, scale buildup can drastically decrease efficiency. By using scale inhibitors, power plants can maintain optimal heat exchange rates and reduce the frequency of cleaning.

2. Oil and Gas During oil extraction, water that is injected to enhance oil recovery often leads to scale formation. Inhibitors help manage scales such as barium sulfate and calcium carbonate, ensuring smoother operations.

3. Water Treatment Scale inhibitors are crucial in municipal water supplies and industrial water treatment processes. They prevent scale in pipes, treatment equipment, and even in household settings.

4. Food and Beverage In the food processing industry, scale formation can impact equipment performance and product quality. Using scale inhibitors ensures consistent operation and product integrity.

Benefits of Using Scale Inhibitors

The advantages of using scale inhibitors are numerous

- Cost Savings By reducing the need for maintenance and downtime caused by scale-related issues, industries save money on repairs and operational disruptions.

- Increased Efficiency Scale inhibitors help maintain optimal operational conditions, leading to improved system efficiency and productivity.

- Extended Equipment Life Preventing scale formation protects equipment from corrosion and wear, thereby extending its lifespan.

- Environmental Compliance Many scale inhibitors are formulated to be environmentally friendly, allowing industries to comply with stricter environmental regulations.

Conclusion

In summary, scale inhibitors play a critical role in maintaining the efficiency and longevity of industrial systems that utilize water. By preventing scale formation through various mechanisms, these chemical agents not only save money but also enhance operational stability across diverse sectors. With continued research and innovation in this field, we can expect even more effective solutions that meet the evolving needs of industries globally.

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025