Flocculation Agents and Their Role in Water Treatment Processes and Applications

Flocculation Chemicals An Overview and Their Applications

Flocculation is a crucial process in various industries, notably in water treatment, food processing, and pharmaceuticals. It involves the aggregation of fine particles into a floc or flake, which can then be easily removed from liquids. This process is essential for clarifying liquids, removing contaminants, and ensuring that products meet safety and quality standards. Flocculation relies heavily on the use of specific chemicals known as flocculants, which facilitate the binding of particles together.

Understanding Flocculation Chemicals

Flocculation chemicals are typically water-soluble polymers or inorganic compounds that enhance the natural process of coagulation. The most commonly used flocculants can be categorized into two main groups organic and inorganic flocculants.

1. Organic Flocculants These are man-made polymers, often derived from natural sources such as starches or synthetic materials. They are especially effective in low concentration situations, making them a popular choice for various applications. Examples of organic flocculants include polyacrylamide, chitosan, and polyethylene oxide. Their high molecular weight allows them to create a bridging effect, which helps in binding and settling particles.

2. Inorganic Flocculants These are typically metal salts, like aluminum sulfate (alum) or ferric chloride. Inorganic flocculants work by neutralizing the charge on suspended particles in water, allowing them to coalesce and settle. This type of flocculant is particularly effective in high turbidity situations, where a large number of fine particles are present.

Applications of Flocculation Chemicals

Flocculation chemicals are widely used across various sectors, each catering to the specific needs of the industry.

- Water Treatment One of the most significant applications of flocculation chemicals is in the treatment of drinking water and wastewater

. Flocculants are employed to remove suspended solid particles, colloids, and other impurities, ensuring that the water meets safety standards for consumption and discharge into natural water bodies.flocculation chemicals

- Food and Beverage Industry In this sector, flocculants are used for clarifying juices, wines, and other liquids. The process helps remove unwanted solid particles, leading to a clearer product with improved taste and shelf-life. Additionally, flocculation chemicals aid in the recovery of valuable by-products and enhance overall processing efficiency.

- Pharmaceutical Industry Flocculation plays a significant role in the purification processes of various pharmaceutical products. Flocculants help in separating Active Pharmaceutical Ingredients (APIs) from impurities, ensuring that medicines are safe and effective for consumer use.

- Mining and Metallurgy In the mining industry, flocculation chemicals are used to help separate valuable minerals from ore slurries. The process increases the efficiency of recovery systems and minimizes environmental impact by reducing waste.

Environmental and Safety Considerations

While flocculation chemicals play an essential role in many processes, attention must be paid to their environmental impact. Some organic flocculants, particularly those derived from synthetic sources, may pose risks to aquatic life if not handled properly. Therefore, it is vital to choose flocculants that are effective yet environmentally friendly. The trend is moving towards biodegradable and non-toxic flocculants, which minimize adverse effects on the ecosystem.

Proper training in handling these chemicals is also vital for employees in industries where flocculation is a standard practice. Understanding the correct dosage, potential hazards, and safety measures can prevent accidents and ensure safe use.

Conclusion

Flocculation chemicals are indispensable in various industrial processes, providing solutions for water treatment, food processing, pharmaceuticals, and more. The choice between organic and inorganic flocculants depends on the specific requirements of each application, such as the nature of the contaminants and the desired outcome. As industries continue to prioritize environmental sustainability, the development of safer and more efficient flocculation chemicals will likely become a critical focus, ensuring that the benefits of flocculation can be realized without compromising environmental integrity.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

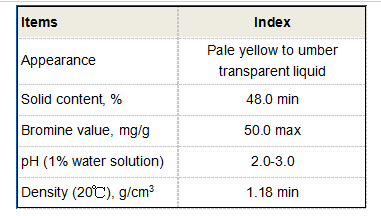

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025