Water Treatment Solutions for Scale Inhibition and Improved System Efficiency

Scale Inhibitor Water Treatment An Overview

Water is an essential resource for various industries, and its quality can significantly impact operational efficiency and equipment lifespan. One of the common challenges faced in water systems is scale formation. Scale, a hard, mineral deposit, can cause severe problems in pipelines, heat exchangers, boilers, and other water-utilizing equipment. This article explores the importance of scale inhibitors in water treatment processes, their mechanisms of action, and their application in different industries.

Understanding Scale Formation

Scale primarily consists of calcium carbonate, calcium sulfate, barium sulfate, and other mineral deposits that occur when water is heated or subjected to pressure changes. As the solubility of these minerals decreases, they precipitate out of the water and adhere to surfaces, creating a barrier that reduces efficiency, increases energy consumption, and can lead to equipment failure. The cost of maintaining and repairing scale-related damage can be significant, making it imperative to find effective solutions.

The Role of Scale Inhibitors

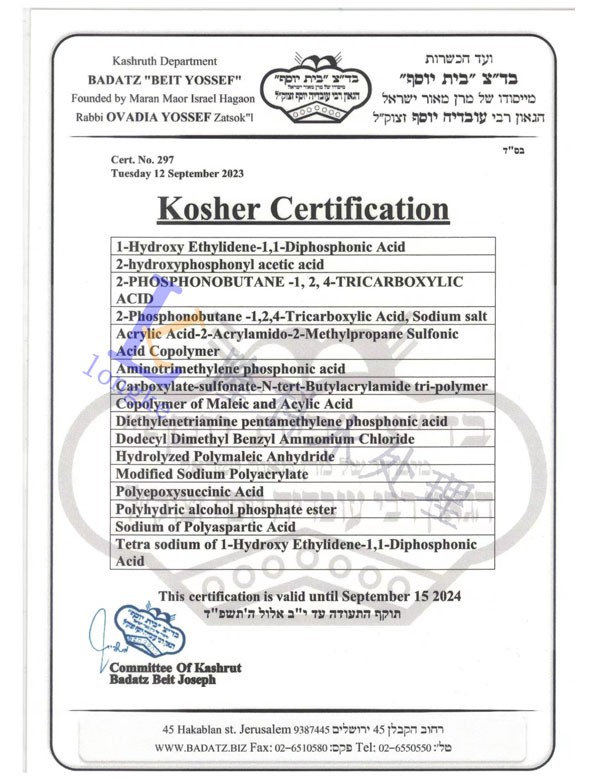

Scale inhibitors are chemical additives designed to prevent or reduce the formation of scale in water systems. They work by altering the properties of the minerals in the water, preventing them from precipitating out and forming deposits. There are several types of scale inhibitors, including phosphonates, polyacrylates, and synthetic polymers. Each type has its specific modes of action and effectiveness depending on the water chemistry and operational conditions.

1. Phosphonates These compounds are widely used for their effectiveness in preventing the formation of calcium carbonate and other mineral scales. They work by binding to crystal growth sites, inhibiting the formation of scale structures, and dispersing already-formed particles.

2. Polyacrylates These are versatile scale inhibitors that not only prevent scale formation but also disperse existing scales. They are particularly effective in controlling a wide range of scales in varying water conditions.

3. Synthetic Polymers These compounds can be tailored for specific applications and are often used in conjunction with other treatment chemicals to optimize performance.

Mechanisms of Action

Scale inhibitors function through various mechanisms, including

scale inhibitor water treatment

- Threshold Inhibition Scale inhibitors reduce the supersaturation level of the scale-forming minerals in the water, preventing precipitation even at concentrations typically considered saturated

.- Crystal Modification They can alter the crystal morphology of scale-forming substances, leading to the formation of non-adherent, smaller particles that are easily removed from the system.

- Dispersion Inhibitors can disperse existing scale and prevent agglomeration, keeping the scale in suspension and reducing the likelihood of buildup on surfaces.

Applications in Various Industries

Scale inhibitors are used across multiple sectors, reflecting their importance in maintaining efficient and effective water systems.

- Power Plants In cooling water systems, scale formation can severely impact heat transfer efficiency. The use of scale inhibitors helps maintain optimal performance and extends the lifespan of critical equipment.

- Oil and Gas In the extraction and transportation of hydrocarbons, scale can occur in pipelines, leading to blockages and production losses. Scale inhibitors are crucial in oilfield water treatment to avoid the costly consequences of scale buildup.

- Food and Beverage Maintaining water quality is vital for sanitation and product quality. Scale prevention helps in the efficiency of processing equipment and adherence to health standards.

- HVAC Systems Scale buildup in heating and cooling systems can lead to increased energy consumption. Regular treatment with scale inhibitors ensures efficient operation and reduced maintenance costs.

Conclusion

In summary, scale inhibitors play a crucial role in water treatment processes by preventing scale formation and improving system efficiency across various industries. The choice of scale inhibitor depends on specific water conditions and operational requirements, making it essential to understand the unique properties of these chemicals. With increasing demands for energy efficiency and equipment longevity, the importance of effective water treatment solutions, including scale inhibitors, will continue to grow. Addressing scale formation not only contributes to operational efficiency but also supports sustainability efforts in industrial water use.

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025