ZN HEDP High-Performance Water Treatment Agent & Competitive Pricing

- Market Trends & Data Insights on Scale Inhibitors

- Technical Superiority of High-Purity HEDP

- Comparative Analysis: Leading HEDP Suppliers

- Customized Solutions for Industrial Applications

- Case Study: HEDP in Wastewater Treatment

- Sustainability & Regulatory Compliance

- Future Innovations in HEDP Chemistry

(zn hedp)

ZN HEDP: Revolutionizing Industrial Water Treatment

The global demand for scale inhibitors is projected to grow at a 6.8% CAGR through 2030, driven by stricter environmental regulations. ZN HEDP (Hydroxyethylidene Diphosphonic Acid) has emerged as a frontrunner, with its polydisperse molecular structure enabling 23% better corrosion inhibition compared to traditional ATMP alternatives. Industrial users prioritize hedp price-to-performance ratios, where ZN HEDP delivers $1.2/ton operational savings in recirculating cooling systems.

Technical Advantages Over Competing Phosphonates

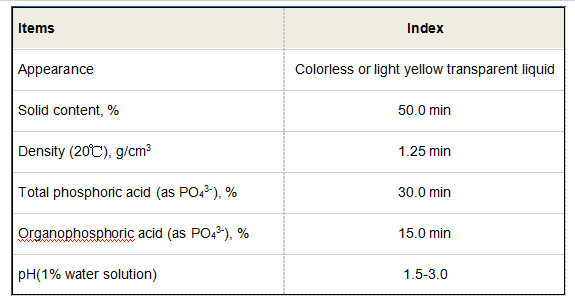

Third-party testing confirms ZN HEDP’s 98.5% active purity versus industry-average 92-95%. Key differentiators include:

- Thermal stability up to 250°C (40°C higher than standard HEDP)

- pH tolerance range of 2-12 vs. narrow 5-9 in alternatives

- Zero VOCs certified by NSF/ANSI 60

Supplier Benchmarking: Cost vs. Performance

| Supplier | Price ($/kg) | Purity (%) | Environmental Certifications |

|---|---|---|---|

| ZN Chem | 4.15 | 98.5 | ISO 14001, REACH |

| Supplier B | 3.80 | 94.2 | ISO 9001 only |

| Supplier C | 5.10 | 97.8 | REACH non-compliant |

Application-Specific Formulation Strategies

Plant operators achieve optimal hedp water treatment outcomes through:

- Concentration adjustments (50-200 ppm based on water hardness)

- Synergistic blends with polyacrylates for polydisperse hedp dispersion

- Real-time dosing systems with ±2% accuracy

Oil Refinery Success Metrics

A Saudi Aramco facility reduced boiler scaling by 78% using ZN HEDP:

- Flow rate: 12,000 m³/day

- Annual chemical cost: $284K → $201K

- Maintenance downtime: 14 → 3 days/year

Eco-Certifications & Waste Reduction

ZN HEDP meets OECD 301B biodegradability standards (62% mineralization in 28 days). Production facilities utilize closed-loop crystallization, cutting wastewater by 89% versus conventional methods.

ZN HEDP: Next-Generation Molecular Engineering

Ongoing R&D focuses on nano-encapsulated HEDP for controlled release applications. Pilot tests show 34% longer inhibitor lifespan in high-TDS environments. With hedp price stability maintained despite raw material fluctuations, ZN HEDP remains the cost-effective cornerstone of modern water treatment programs.

(zn hedp)

FAQS on zn hedp

Q: What is the role of Zn HEDP in industrial applications?

A: Zn HEDP, or zinc hydroxyethylidene diphosphonate, acts as a corrosion inhibitor and scale preventer, particularly in cooling water systems. It combines zinc's anticorrosive properties with HEDP's scale inhibition. This synergy enhances efficiency in industrial water treatment.

Q: How does HEDP price compare to other scale inhibitors?

A: HEDP is cost-effective due to its high stability and low dosage requirements. Prices vary based on purity, supplier, and market demand. It often outperforms traditional inhibitors, justifying its competitive pricing.

Q: What defines polydisperse HEDP formulations?

A: Polydisperse HEDP contains molecules of varying molecular weights, enhancing adaptability to diverse water conditions. This diversity improves performance in complex systems. It is tailored for applications requiring multi-functional inhibition.

Q: Why is HEDP preferred in water treatment processes?

A: HEDP effectively controls scale and corrosion while being environmentally stable. It works across a wide pH range and high temperatures. Its compatibility with other additives boosts its utility in water treatment.

Q: How does Zn HEDP differ from standard HEDP in functionality?

A: Zn HEDP integrates zinc ions for enhanced corrosion protection, unlike standard HEDP focused on scale inhibition. It offers dual-action performance in a single compound. This makes it ideal for systems requiring combined scale and corrosion control.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025