Acrylic Polymers: Essential Solutions for Industry

Acrylic homopolymer is one of the most widely used polymers in various industries due to its versatile properties. Made from acrylic acid or acrylate monomers, acrylic homopolymer is known for its exceptional clarity, durability, and resistance to weathering. These qualities make it ideal for applications in areas such as coatings, adhesives, textiles, and medical devices.

One of the key advantages of acrylic homopolymer is its high resistance to UV radiation, which allows it to retain its strength and clarity even when exposed to the elements for prolonged periods. This makes it a popular choice for outdoor applications like signage, windows, and automotive parts. Additionally, acrylic homopolymer offers excellent chemical resistance, making it a reliable material for use in harsh chemical environments.

Manufacturers looking for a high-performance material for both indoor and outdoor applications often turn to acrylic homopolymer because of its adaptability and durability. The polymer's ability to maintain its properties in diverse environments makes it an invaluable component in many industries.

Acrylic Acid Homopolymer

An important derivative of acrylic acid, the acrylic acid homopolymer is widely used in the production of water-absorbing materials, superabsorbent polymers, and flocculants. The unique properties of acrylic acid homopolymer, such as its ability to form gel-like substances, make it particularly useful in industries ranging from hygiene products to oil recovery.

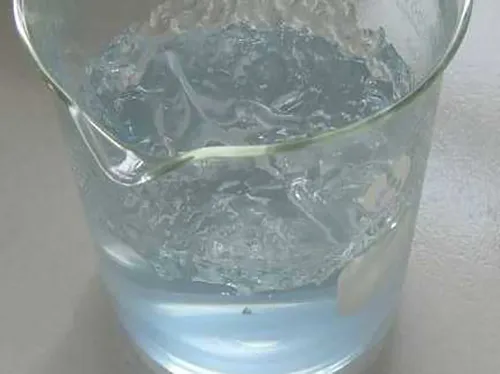

Acrylic acid homopolymer is produced by polymerizing acrylic acid, which forms a substance with strong ionic properties. These properties allow it to absorb water and swell, making it ideal for applications like diapers, feminine hygiene products, and even certain types of soil conditioners. The acrylic acid homopolymer's versatility also extends to water treatment processes, where it is used as a flocculant to aid in the removal of suspended particles.

The ability to tailor the polymer's characteristics through modification has made acrylic acid homopolymer an essential ingredient in many advanced products, ensuring efficiency and performance in industries where absorption and water retention are critical.

LK-1100 Modified Polyacrylic Acid

For those in need of a highly specialized polymer, LK-1100 Modified Polyacrylic Acid is an excellent choice. This advanced product is a modified version of polyacrylic acid that has been engineered to offer enhanced performance in specific applications. The LK-1100 Modified Polyacrylic Acid offers superior water retention, viscosity control, and adhesion properties, making it suitable for industries like oil recovery, water treatment, and the cosmetic industry.

What sets LK-1100 Modified Polyacrylic Acid apart is its ability to work in both high- and low-pH environments, ensuring optimal performance across various conditions. This polymer is often used in formulations for cleaning agents, where it can act as a thickener or stabilizer, improving the product's performance and efficiency. Its modified structure enhances its ability to create stronger bonds with particles, leading to better results in applications like water treatment and industrial cleaning.

For manufacturers looking for a versatile, high-performance polymer that can be tailored to specific needs, LK-1100 Modified Polyacrylic Acid offers a reliable solution that stands out in terms of both performance and versatility.

Uses and Applications of Acrylic Polymers

The uses of acrylic polymers, including acrylic homopolymer, acrylic acid homopolymer, and LK-1100 Modified Polyacrylic Acid, are extensive and cover a wide range of industries. From automotive to healthcare, the applications of these polymers have become increasingly important.

For example, acrylic homopolymer is frequently used in the production of automotive parts, especially those requiring durability and UV resistance. In the construction industry, acrylic homopolymer is used in coatings and adhesives, where its excellent bonding properties ensure long-lasting performance.

In water treatment, acrylic acid homopolymer plays a critical role in improving the quality of water by removing contaminants. As a flocculant, it aids in the removal of suspended solids, ensuring cleaner water for consumption and industrial use. Similarly, LK-1100 Modified Polyacrylic Acid is invaluable in industries like oil and gas, where its superior performance as a dispersant and stabilizer makes it ideal for applications like drilling fluids and enhanced oil recovery.

By incorporating these advanced polymers, industries can improve the efficiency and effectiveness of their products, making acrylic homopolymer, acrylic acid homopolymer, and LK-1100 Modified Polyacrylic Acid essential materials in modern manufacturing.

Acrylic Acid Homopolymer FAQs

What are the main uses of acrylic homopolymer?

Acrylic homopolymer is used primarily in industries like coatings, adhesives, automotive, and textiles. Its high clarity, UV resistance, and chemical durability make it ideal for outdoor applications like signage and automotive parts.

How does acrylic acid homopolymer work in water treatment?

Acrylic acid homopolymer is used in water treatment as a flocculant. It helps to aggregate suspended particles, making it easier to remove them from water during filtration or sedimentation processes.

What makes LK-1100 Modified Polyacrylic Acid unique?

LK-1100 Modified Polyacrylic Acid is a specialized polymer known for its superior water retention, viscosity control, and adhesion properties. It performs well in both high- and low-pH environments, making it highly versatile for various applications, including oil recovery and water treatment.

Can LK-1100 Modified Polyacrylic Acid be used in the cosmetic industry?

Yes, LK-1100 Modified Polyacrylic Acid is used in the cosmetic industry as a thickening agent and stabilizer. Its unique properties make it effective in creating smooth and consistent formulations for skincare and beauty products.

How does the price of acrylic acid homopolymer compare to other polymers?

The price of acrylic acid homopolymer is competitive within the polymer market, but it can vary depending on factors such as grade and manufacturer. It offers high performance at a relatively affordable cost, making it an attractive option for industries that require flocculation or water absorption.

Polymers like acrylic homopolymer, acrylic acid homopolymer, and LK-1100 Modified Polyacrylic Acid play vital roles across various industries. These advanced materials offer exceptional versatility and performance, making them indispensable in sectors ranging from water treatment to cosmetics. By understanding their unique properties and applications, manufacturers can make informed choices to optimize their products and ensure efficiency in their processes.

-

Understanding Polycarboxylic Acids: Properties, Applications, and Future PotentialBalitaJul.28,2025

-

Scale Inhibitor Explained: How to Protect Your System from Limescale and Hard Water DamageBalitaJul.28,2025

-

Scale and Corrosion Inhibitors: Essential Chemicals for Industrial Water System ProtectionBalitaJul.28,2025

-

Polyaspartic Acid: A Biodegradable Polymer for Sustainable ChemistryBalitaJul.28,2025

-

Isothiazolinones: A Versatile Antimicrobial Class with Industrial Power and Regulatory ChallengesBalitaJul.28,2025

-

A Deep Dive into 2-Phosphonobutane-1,2,4-Tricarboxylic Acid (PBTC)BalitaJul.28,2025