Led . 09, 2025 10:37

Back to list

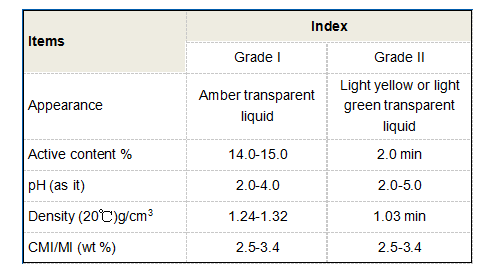

LK-3100 Carboxylate-Sulfonate-Nonion Terpolymer

Selecting the right flocculant manufacturer is a critical decision for industries reliant on water treatment, mining, paper production, and other fields where separating particles from liquids is required. The expertise and technology provided by these manufacturers can significantly impact efficiency and environmental outcomes. To achieve optimal results, understanding the core attributes of a top-tier flocculant manufacturer can guide your selection process.

Trustworthiness is achieved through a transparent and customer-oriented approach. Manufacturers who prioritize building strong relationships with their clients often provide detailed product information, performance data, and post-sale support services. They are open to feedback and continuously strive to improve their product lines based on client experiences and technological advancements. Trustworthy manufacturers also offer comprehensive testing services and pilot trials, allowing clients to assess the performance of flocculants under real operating conditions before full-scale implementation. Furthermore, cutting-edge technology integration sets apart leading manufacturers. Those investing in research and development focus on creating more sustainable and efficient flocculant solutions. For example, innovative manufacturers are developing bio-based flocculants that reduce environmental impact without compromising on performance. These advancements not only align with global sustainability goals but also provide clients with solutions that are future-proof and adaptable to evolving industry standards. In summary, the choice of a flocculant manufacturer should be guided by the company’s experience, expertise, authority, and trustworthiness. The optimal manufacturer will not only have a history of offering high-quality, effective products but also demonstrate an unwavering commitment to advancing their field. By choosing a manufacturer that excels in these areas, industries can ensure that their flocculation processes are efficient, cost-effective, and environmentally responsible.

Trustworthiness is achieved through a transparent and customer-oriented approach. Manufacturers who prioritize building strong relationships with their clients often provide detailed product information, performance data, and post-sale support services. They are open to feedback and continuously strive to improve their product lines based on client experiences and technological advancements. Trustworthy manufacturers also offer comprehensive testing services and pilot trials, allowing clients to assess the performance of flocculants under real operating conditions before full-scale implementation. Furthermore, cutting-edge technology integration sets apart leading manufacturers. Those investing in research and development focus on creating more sustainable and efficient flocculant solutions. For example, innovative manufacturers are developing bio-based flocculants that reduce environmental impact without compromising on performance. These advancements not only align with global sustainability goals but also provide clients with solutions that are future-proof and adaptable to evolving industry standards. In summary, the choice of a flocculant manufacturer should be guided by the company’s experience, expertise, authority, and trustworthiness. The optimal manufacturer will not only have a history of offering high-quality, effective products but also demonstrate an unwavering commitment to advancing their field. By choosing a manufacturer that excels in these areas, industries can ensure that their flocculation processes are efficient, cost-effective, and environmentally responsible.

Share

Latest news

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025