polyacrylamide production

The Production of Polyacrylamide A Comprehensive Overview

Polyacrylamide is a widely used polymer known for its versatility and effectiveness in various applications, particularly in water treatment, soil conditioning, and the oil and gas industry. The production of polyacrylamide involves several key processes, each critical in determining the quality and characteristics of the final product. Understanding these steps is essential for optimizing production and ensuring the polymer meets specific requirements for its intended uses.

1. Raw Materials

The primary raw material for polyacrylamide production is acrylamide, a monomer derived from the reaction of propylene with chlorine in the presence of sodium hydroxide. The quality of acrylamide is crucial, as impurities can affect the polymerization process and the properties of the final product. Additionally, other materials such as initiators, which can be thermal or redox initiators, and cross-linking agents are necessary for controlling the degree of polymerization and the structure of the resulting polyacrylamide.

2. Polymerization Process

The actual production of polyacrylamide begins with the polymerization of acrylamide. This process can take place in various mediums, including aqueous solutions, to ensure the proper reaction conditions. There are two main types of polymerization methods used solution polymerization and suspension polymerization.

- Solution Polymerization This method allows for the reaction to take place in a predominantly aqueous solution. Here, the acrylamide monomer is dissolved in water, and the initiators are added to start the chain reaction.

- Suspension Polymerization In contrast, suspension polymerization involves dispersing the acrylamide in an inert liquid, which prevents the formation of large aggregates and results in a more uniform product.

polyacrylamide production

The choice of polymerization method and conditions such as temperature, pH, and concentration of initiators significantly influences the molecular weight of the polyacrylamide, which in turn affects its solubility and effectiveness in various applications.

After polymerization, the polyacrylamide product often contains unreacted monomers, initiators, and other impurities. These must be removed to ensure product safety and performance. Various techniques, such as filtration, precipitation, or washing with solvents, are employed for purification.

Following purification, the polyacrylamide is typically dried to reduce moisture content, which is crucial for storage and handling. Drying methods can include spray drying or freeze-drying, depending on the desired form of the product, whether as powder or granules.

4. Applications

Polyacrylamide's unique properties make it suitable for a wide range of applications. In water treatment, it serves as a flocculant, helping to remove impurities from water through coagulation and sedimentation. In agriculture, it acts as a soil conditioner, enhancing moisture retention and promoting plant growth. Furthermore, in the oil and gas industry, polyacrylamide is utilized in enhanced oil recovery techniques, improving the extraction of crude oil from reservoirs.

Conclusion

The production of polyacrylamide involves meticulous processes that require careful control and optimization to yield a high-quality product. As demand for this versatile polymer continues to grow globally, advances in production technology and methodologies will play a crucial role in meeting the needs of various industries efficiently and sustainably. Understanding the intricacies of polyacrylamide production not only enhances its applications but also ensures better environmental management in its use and disposal.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

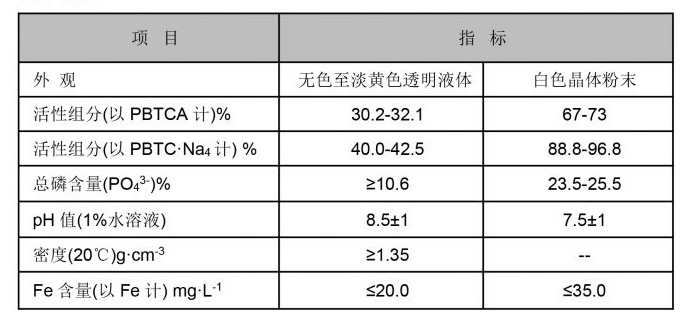

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025