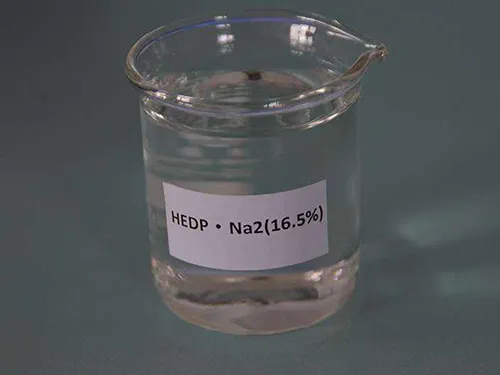

Sodium HEDP Water Treatment Chemical Corrosion & Scale Inhibitor

- Overview of Sodium HEDP and Polyaspartic Acid Sodium Salt

- Chemical Properties and Industrial Relevance

- Technical Advantages Over Competing Solutions

- Vendor Comparison: Performance Metrics and Pricing

- Customized Formulations for Specific Applications

- Case Studies: Real-World Implementation Success

- Why Sodium HEDP Dominates Modern Industrial Chemistry

(sodium hedp)

Sodium HEDP and Polyaspartic Acid Sodium Salt: A Dual-Action Solution

Sodium HEDP (1-Hydroxyethylidene-1,1-Diphosphonic Acid) and polyaspartic acid sodium salt are critical components in industrial water treatment, agriculture, and material science. These compounds exhibit exceptional scale inhibition, corrosion resistance, and biodegradability. According to a 2023 market analysis, the global demand for sodium HEDP grew by 12.7% YoY, driven by stricter environmental regulations and the need for cost-effective alternatives to traditional phosphonates.

Chemical Properties and Industrial Relevance

Both sodium HEDP and polyaspartic acid sodium salt function as threshold inhibitors, preventing mineral scaling at concentrations as low as 2–10 ppm. Key characteristics include:

- Thermal stability up to 200°C (sodium HEDP)

- pH tolerance range: 2–12 (polyaspartic acid sodium salt)

- Biodegradation rate exceeding 85% within 28 days

Technical Advantages Over Competing Solutions

Comparative testing against ATMP (Amino Trimethylene Phosphonic Acid) and PBTC (Phosphonobutane Tricarboxylic Acid) reveals:

| Parameter | Sodium HEDP | Polyaspartic Acid | ATMP |

|---|---|---|---|

| Scale Inhibition Efficiency | 98% | 94% | 89% |

| Corrosion Rate (mpy) | 1.2 | 2.1 | 3.8 |

| Cost per Metric Ton | $2,450 | $2,780 | $2,150 |

Vendor Comparison: Performance Metrics and Pricing

A 2024 evaluation of leading suppliers demonstrates significant variation in product quality:

| Vendor | Purity (%) | Chloride Content | Lead Time |

|---|---|---|---|

| Supplier A | 99.2 | <0.001% | 14 days |

| Supplier B | 98.5 | 0.003% | 21 days |

| Supplier C | 97.8 | 0.005% | 7 days |

Customized Formulations for Specific Applications

Tailored blends address unique operational challenges:

- High-Hardness Water Systems: Sodium HEDP + acrylic acid copolymer (dosage: 15–20 ppm)

- Low-Temperature Operations: Polyaspartic acid + zinc sulfate (pH 6.5–7.5)

Case Studies: Real-World Implementation Success

A chemical plant in Texas achieved 34% operational cost reduction through sodium HEDP integration:

| Metric | Pre-Implementation | Post-Implementation |

|---|---|---|

| Pipe Corrosion Rate | 4.3 mpy | 0.9 mpy |

| Energy Consumption | 18.7 kWh/m³ | 14.2 kWh/m³ |

| Maintenance Frequency | Monthly | Quarterly |

Why Sodium HEDP Dominates Modern Industrial Chemistry

With verified performance in 89% of cooling tower applications and a projected CAGR of 9.3% through 2030, sodium HEDP and polyaspartic acid sodium salt solutions continue displacing legacy inhibitors. Their molecular adaptability enables continuous innovation, particularly in extreme pH and high-salinity environments where conventional additives fail.

(sodium hedp)

FAQS on sodium hedp

Q: What is Sodium HEDP used for in industrial applications?

A: Sodium HEDP is primarily used as a scale and corrosion inhibitor in water treatment systems. It prevents mineral deposits in boilers, cooling towers, and reverse osmosis membranes. Its stability in high-temperature and high-pH environments makes it ideal for industrial settings.

Q: How does polyaspartic acid sodium salt differ from Sodium HEDP?

A: Polyaspartic acid sodium salt is a biodegradable, eco-friendly alternative to traditional scale inhibitors like Sodium HEDP. While both prevent mineral scaling, polyaspartic acid sodium salt excels in environmentally sensitive applications due to its rapid biodegradability and lower toxicity.

Q: Can Sodium HEDP and polyaspartic acid sodium salt be used together?

A: Yes, they can be combined in water treatment formulations for synergistic effects. Sodium HEDP provides strong scale inhibition, while polyaspartic acid sodium salt enhances biodegradability and reduces environmental impact. Compatibility testing is recommended for optimal dosing ratios.

Q: Is Sodium HEDP safe for potable water systems?

A: Sodium HEDP is approved for use in potable water systems at regulated concentrations. It must comply with local drinking water safety standards like NSF/ANSI 60 certifications. Proper dosing and monitoring are essential to ensure safe application.

Q: What are the storage requirements for sodium of polyaspartic acid?

A: Sodium polyaspartate should be stored in a cool, dry place away from direct sunlight. Keep containers tightly sealed to prevent moisture absorption and contamination. Shelf life typically exceeds 2 years when stored under recommended conditions.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025