Assessing the Impact of Scale and Corrosion Inhibitors in Industrial Applications

Scale and Corrosion Inhibitor Chemicals Essential Solutions for Industrial Efficiency

In a world where efficient industrial processes are paramount, the management of scale and corrosion in systems that involve water and other fluids is a significant challenge. Scale formation and corrosion not only decrease the operational efficiency of equipment but also lead to increased maintenance costs, potential downtimes, and even equipment failure. This article delves into the nature of scale and corrosion, the role of inhibitor chemicals, and their importance in various industries.

Understanding Scale and Corrosion

Scale refers to the buildup of minerals, such as calcium carbonate and magnesium sulfate, that occurs in water systems due to temperature and pressure changes. This mineral accumulation often leads to reduced flow rates, decreased heat exchange efficiency, and ultimately increased energy consumption. On the other hand, corrosion is the degradation of materials, particularly metals, caused by electrochemical reactions with the environment. This can lead to weakened structures, leaks, and even catastrophic failures if not properly managed.

Both scale and corrosion are particularly problematic in industries that rely heavily on water systems, such as power generation, oil and gas, chemical processing, and HVAC (heating, ventilation, and air conditioning). The economic repercussions of neglecting these issues can be substantial, thus, proper chemical treatment solutions are essential.

The Role of Inhibitor Chemicals

Inhibitor chemicals are specifically formulated to prevent or reduce the rates of scale formation and corrosion. These chemicals modify the properties of the liquid phase and the solid surfaces to which they adhere. They achieve this through various mechanisms, including forming protective films on metal surfaces to prevent corrosion, modifying crystal growth patterns to inhibit scale formation, and dispersing existing deposits in the system.

There are several types of scale and corrosion inhibitors available on the market, including

1. Corrosion Inhibitors These chemicals, such as amines, phosphates, and nitrites, function by reacting with the metal surface to create a protective barrier that mitigates corrosion. They can be used in both acidic and alkaline conditions, making them versatile options for various industrial applications.

2. Scale Inhibitors Commonly utilized are polyphosphates, phosphonates, and acrylic copolymers, which work by interfering with the crystallization process of scale-forming minerals. They reduce the tendency of minerals to precipitate out of solution and form solid deposits.

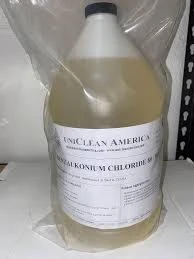

scale and corrosion inhibitor chemicals

3. Biocides In contexts where microbial-induced corrosion (MIC) is a concern, biocides can be added to water treatment programs. These prevent the growth of bacteria and microorganisms that contribute to corrosion and biofilm formation.

Importance of Scale and Corrosion Inhibitors

Implementing scale and corrosion inhibitors is vital for several reasons

- Cost Efficiency Preventive measures reduce the need for extensive maintenance and repairs, thereby lowering operational costs. Regular use of inhibitors can postpone or eliminate costly downtime associated with equipment failures.

- Energy Savings Equipment that is free of scale and corrosion operates more efficiently, leading to lower energy requirements. This not only translates to cost savings but also supports environmental sustainability by reducing energy consumption.

- Enhanced Equipment Lifespan By protecting critical infrastructure, inhibitors extend the lifespan of equipment and reduce the frequency of replacements. This is particularly beneficial in capital-intensive industries where equipment represents a significant investment.

- Regulatory Compliance Many industries face stringent regulations regarding water use and waste management. Inhibitors can help maintain compliance by promoting efficient water use and reducing the environmental impact of industrial operations.

Conclusion

Scale and corrosion are inevitable challenges in water-based systems across various industries. However, with the strategic application of scale and corrosion inhibitor chemicals, businesses can safeguard their equipment, enhance efficiency, and ultimately drive profitability. As industries continue to strive for operational excellence, the role of these chemical solutions will remain crucial in ensuring long-term sustainability and performance stability. The future of industrial operations hinges upon understanding and effectively managing these critical factors, making scale and corrosion inhibitors indispensable in the modern industrial landscape.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025