scale inhibitor

Understanding Scale Inhibitors Importance and Applications

Scale inhibitors play a crucial role in various industrial processes where water is used. The term scale refers to the hard, mineral deposits that form on equipment and surfaces as a result of the precipitation of dissolved minerals from water. These deposits can cause significant operational inefficiencies, increase maintenance costs, and even lead to equipment failure. Therefore, the use of scale inhibitors is essential in many sectors, including oil and gas, power generation, water treatment, and cooling systems.

What Are Scale Inhibitors?

Scale inhibitors are chemical compounds that prevent or reduce the formation of scale. They work by interfering with the crystallization process of minerals such as calcium carbonate, calcium sulfate, and barium sulfate. By altering the growth of these crystals, scale inhibitors help to keep them suspended in the water rather than allowing them to settle on surfaces. This is particularly important in systems where water is heated, as higher temperatures can accelerate scale formation.

Types of Scale Inhibitors

There are several types of scale inhibitors, each designed for specific applications and conditions

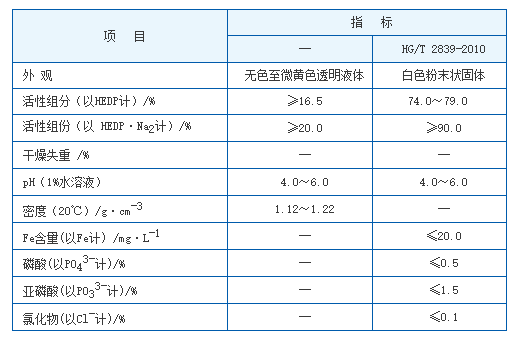

. The most common types include1. Phosphonates These compounds are effective against calcium carbonate and other scales and are often used in cooling systems and oilfield waters. 2. Polyacrylic Acid Known for their excellent dispersing properties, polyacrylic acids are widely used in both cooling towers and domestic water systems. 3. Sulfonate Polymers These offer broad-spectrum scale inhibition and are effective in high-temperature applications, such as power plants.

scale inhibitor

4. Organic and Inorganic Acids While primarily used for cleaning purposes, these acids can also prevent scale formation when used appropriately in small concentrations.

Applications of Scale Inhibitors

In industrial settings, the application of scale inhibitors is paramount. For example, in the oil and gas industry, scale formation can block the flow of oil or gas, leading to production losses. Scale inhibitors are used in water flood operations to maintain the integrity of the well and maximize oil recovery.

In power plants, the presence of scale in cooling towers can reduce heat exchange efficiency, thereby increasing operational costs. By incorporating scale inhibitors into the cooling water treatment processes, plants can significantly improve their efficiency and extend the lifespan of their equipment.

In the realm of water treatment, scale inhibitors are added to municipal water supplies and residential plumbing systems to prevent scale buildup in pipes and appliances, thereby ensuring better performance and longevity.

Conclusion

The importance of scale inhibitors cannot be overstated. As industries continue to seek greater efficiency and lower costs, the role of these chemical agents will only become more critical. By preventing scale formation, scale inhibitors help maintain equipment performance, reduce maintenance costs, and increase the overall efficiency of industrial processes. Their application across various sectors underscores their versatility and essential contribution to modern industry and infrastructure.

-

Understanding Polycarboxylic Acids: Properties, Applications, and Future PotentialNewsJul.28,2025

-

Scale Inhibitor Explained: How to Protect Your System from Limescale and Hard Water DamageNewsJul.28,2025

-

Scale and Corrosion Inhibitors: Essential Chemicals for Industrial Water System ProtectionNewsJul.28,2025

-

Polyaspartic Acid: A Biodegradable Polymer for Sustainable ChemistryNewsJul.28,2025

-

Isothiazolinones: A Versatile Antimicrobial Class with Industrial Power and Regulatory ChallengesNewsJul.28,2025

-

A Deep Dive into 2-Phosphonobutane-1,2,4-Tricarboxylic Acid (PBTC)NewsJul.28,2025