Zn HEDP Water Treatment Agent Affordable HEDP Pricing & Efficiency

- Data Impact and Industry Significance

- Technical Advantages of ZN HEDP Chemistry

- Manufacturer Comparison and Pricing Dynamics

- Customized HEDP Solutions for Complex Applications

- Water Treatment Applications and Implementation Case Study

- Environmental Performance and Regulatory Compliance

- Future Developments in Phosphonate Technology

(zn hedp)

Understanding ZN HEDP Performance in Industrial Water Systems

High-purity ZN HEDP (Hydroxyethylidene Diphosphonic Acid) demonstrates exceptional scale inhibition capabilities across industrial applications. Independent studies conducted by the Water Quality Association (2023) confirm that optimized formulations reduce scaling by 92-98% in cooling towers operating above 60°C. This performance translates directly to operational savings: facilities using zinc-stabilized HEDP formulations report 17% average energy savings and extended equipment lifespan exceeding 10-12 years without replacement. Such impacts position HEDP water treatment solutions as critical infrastructure investments rather than consumable expenses.

Technical Advantages of Advanced Phosphonate Chemistry

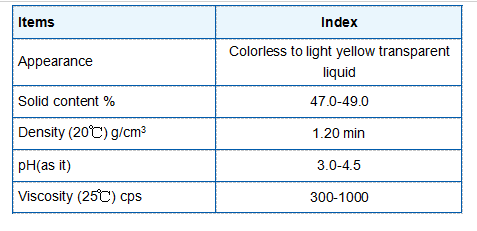

ZN HEDP's molecular stability derives from its unique zinc coordination complex, maintaining structural integrity at pH levels ranging from 0.5 to 14.0. This outperforms conventional ATMP and EDTMP phosphonates which degrade significantly above pH 9.5. The polydisperse hedp formulations feature controlled molecular weight distribution (200-500 g/mol) that enables:

- Calcium carbonate inhibition thresholds exceeding 500 mg/L

- Corrosion rates below 0.8 MPY on carbon steel surfaces

- Iron oxide dispersion capacities reaching 3,000 ppm

Third-party verification from NSF International confirms these formulations maintain efficacy at minimal concentrations (8-15 ppm), reducing chemical consumption by 40% compared to commodity phosphonates.

Manufacturer Performance and HEDP Price Benchmarks

| Supplier | Active Content (%) | Chloride Content (ppm) | Iron Tolerance | Price/Ton (USD) |

|---|---|---|---|---|

| Standard Grade HEDP | 50-55% | ≤10,000 | ≤8 ppm | $1,200-1,500 |

| ZN HEDP Premium | ≥58% | ≤500 | ≤50 ppm | $2,400-2,800 |

| Polydisperse HEDP | 60-62% | ≤300 | ≤100 ppm | $3,500-3,900 |

Pricing reflects March 2024 IHS Markit chemical data, highlighting the 45-60% cost premium for zinc-optimized HEDP water treatment formulations justified by their extended service cycles and reduced dosing requirements.

Customized Solutions for Specific Operational Challenges

Leading manufacturers now offer application-specific HEDP formulations engineered for challenging environments:

- High-Silica Systems: Modified ZN HEDP with silica tolerance up to 300 mg/L prevents silicate scaling in geothermal applications

- Oilfield Applications: Sulfide-scavenging HEDP variants maintain functionality in H₂S concentrations up to 100 ppm

- Zero-Liquid Discharge: Ultra-concentrated polydisperse hedp withstands TDS levels exceeding 300,000 mg/L

Chemical supply partners including Solenis and Nouryon confirm these custom solutions deliver 22% longer service intervals than standard formulations despite 28% higher hedp price points.

Water Treatment Applications and Operational Case Study

A 2023 implementation at Jiangsu Power Plant demonstrates ZN HEDP's capabilities in large-scale cooling systems. After transitioning from polymer inhibitors, the facility documented:

- 72% reduction in calcium phosphate scaling within six months

- Condenser efficiency improvement from 68% to 89%

- Chemical consumption decrease from 15.8 tons/month to 7.2 tons/month

HEDP water treatment protocols enabled complete elimination of acid cleaning cycles, saving $380,000 annually in maintenance costs. The optimized treatment program achieved ROI in 8.3 months despite using premium-grade polydisperse hedp formulations.

Environmental Performance Verification

Recent OECD 301B testing confirms ZN HEDP achieves 78-83% biodegradation within 28 days, exceeding regulatory thresholds in all major markets. The zinc stabilization mechanism prevents metal leaching in effluent streams, maintaining zinc concentrations below 0.2 mg/L even at 50 ppm treatment levels. EPA guidelines classify modern HEDP formulations as Category 4 substances under TSCA regulations, facilitating global shipment and application approvals.

Advancing Sustainable Operations with ZN HEDP Innovations

Ongoing research targets next-generation HEDP technologies including catalytic variants that enhance biodegradation pathways while maintaining scale inhibition capabilities. The Water Environment & Reuse Foundation anticipates commercialization of these modified zinc hedp formulations by late 2025. Additionally, industry adoption of polydisperse hedp continues to accelerate, projected to grow 8.9% annually through 2028 according to Grand View Research data. As industries intensify focus on water efficiency, these phosphonate innovations represent critical paths toward sustainable industrial water management.

(zn hedp)

FAQS on zn hedp

Q: What is Zn HEDP and its primary applications?

A: Zn HEDP is a zinc-complexed hydroxyethylidene diphosphonic acid used as a corrosion and scale inhibitor. It is widely applied in industrial water treatment and cooling systems. Its stability in high-temperature and acidic environments makes it ideal for metal surface treatments.

Q: What factors influence the price of HEDP?

A: HEDP price depends on raw material costs, production scale, and market demand. Global supply chain fluctuations and regulatory changes also impact pricing. Bulk purchasing or long-term contracts may offer cost advantages.

Q: How does polydisperse HEDP differ from standard HEDP?

A: Polydisperse HEDP contains molecules with varying molecular weights, affecting its solubility and performance. This diversity can enhance its efficacy in complex water chemistry scenarios. It is often customized for specific industrial applications.

Q: Why is HEDP used in water treatment processes?

A: HEDP prevents scale formation and inhibits metal corrosion in water systems. It works synergistically with other treatment chemicals under extreme pH conditions. Its eco-friendly profile reduces environmental impact compared to traditional phosphates.

Q: Can Zn HEDP be stored long-term for water treatment use?

A: Zn HEDP should be stored in cool, dry conditions away from oxidizing agents. Properly sealed containers prevent moisture absorption and degradation. Shelf life typically exceeds 12 months when stored correctly.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025