Understanding the Properties and Applications of Hydrolyzed Polymaleic Anhydride in Industry

Hydrolyzed Polymaleic Anhydride Versatile Applications and Properties

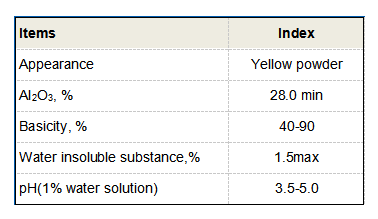

Hydrolyzed polymaleic anhydride (HPMA) is a synthetic polymer derived from the polymerization of maleic anhydride, followed by hydrolysis. This polymer has garnered significant attention in various industries due to its unique chemical properties and versatility in applications. Understanding HPMA’s composition, characteristics, and uses can reveal the potential benefits it offers across different fields.

The structure of HPMA comprises repeating units of maleic acid, which are formed when maleic anhydride undergoes hydrolysis. This process results in a water-soluble polymer that retains the functional groups essential for various interactions. The hydrolysis not only alters the solubility of polymaleic anhydride but also enhances its reactivity, making it suitable for various chemical modifications and applications.

One of the key properties of hydrolyzed polymaleic anhydride is its ability to act as a dispersant and scale inhibitor, especially in water treatment processes. When used in cooling systems, for instance, HPMA prevents the formation of scales that can inhibit heat transfer and reduce efficiency. By keeping minerals in suspension, it ensures that the systems function optimally and reduces maintenance costs associated with scale buildup.

Additionally, HPMA exhibits excellent binding properties, making it useful in the formulation of paints, coatings, and adhesives. Its ability to disperse pigments evenly allows for uniform color and consistency in finishes. This characteristic is particularly valuable in the construction and automotive industries, where high-quality coatings are essential for both aesthetic and protective purposes.

hydrolyzed polymaleic anhydride

Furthermore, HPMA’s biocompatibility has sparked interest in biomedical applications, particularly in drug delivery systems. The polymer can be used to encapsulate therapeutic agents, enhancing their solubility and stability while controlling their release. This property makes HPMA an attractive candidate for developing advanced pharmaceuticals aimed at targeted therapy, where controlled dosage is crucial for effectiveness.

In the realm of agriculture, HPMA has been explored as a potential agent for enhancing soil quality and nutrient availability. When applied to soil, it can improve water retention and nutrient absorption, leading to better crop yields. The polymer’s ability to interact with various soil components allows for effective nutrient binding, facilitating a more sustainable approach to agriculture in an era where resource efficiency is paramount.

Moreover, hydrolyzed polymaleic anhydride is utilized in various industrial processes, including oil and gas extraction. By acting as a low-viscosity fluid, it aids in improving the flow of crude oil and helps in the formulation of fracking fluids, thus enhancing extraction efficiency while minimizing environmental impact.

In conclusion, hydrolyzed polymaleic anhydride is a multifaceted polymer with far-reaching implications across various industries. Its unique properties, such as its ability to prevent scale formation, enhance binding, facilitate drug delivery, improve soil conditions, and assist in industrial applications, position it as a valuable compound in contemporary science and technology. As research continues and new applications are discovered, HPMA is likely to play an even more significant role in advancing various fields, making it an essential substance in both current and future innovations.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025