Sodium HEDP High-Efficiency Corrosion & Scale Inhibitor Supplier

This blog provides a comprehensive analysis of sodium HEDP and its derivatives, focusing on technical advantages, market trends, and practical applications. Below is the structured outline:

- Understanding Sodium HEDP and Its Industrial Significance

- Market Data: Growth Projections and Demand Drivers

- Technical Advantages Over Competing Corrosion Inhibitors

- Manufacturer Comparison: Performance Metrics

- Customized Solutions for Diverse Industrial Needs

- Case Studies: Real-World Applications

- Future Outlook: Sodium HEDP’s Role in Sustainable Chemistry

(sodium hedp)

Understanding Sodium HEDP and Its Industrial Significance

Sodium HEDP (1-Hydroxyethylidene-1,1-Diphosphonic Acid Sodium Salt) is a high-performance scale and corrosion inhibitor widely used in water treatment, oilfield chemistry, and industrial cleaning. As a derivative of polyaspartic acid sodium salt, it combines biodegradability with exceptional chelation properties. The global market for sodium HEDP is projected to grow at a 6.8% CAGR between 2023 and 2030, driven by increasing demand for eco-friendly alternatives to traditional phosphonates.

Market Data: Growth Projections and Demand Drivers

Recent studies indicate that sodium HEDP accounts for 32% of the global phosphonate inhibitor market, with Asia-Pacific dominating production (58% share). Key sectors fueling demand include:

- Water treatment: 47% of total consumption

- Oil & gas: 29%

- Agriculture: 18%

Regulatory shifts, such as the EU’s REACH Directive, have accelerated adoption rates by 22% since 2020, favoring sodium HEDP’s lower environmental impact compared to ATMP or EDTMP alternatives.

Technical Advantages Over Competing Corrosion Inhibitors

Sodium HEDP demonstrates superior stability in high-temperature (up to 250°C) and high-pH (9–12) environments. Comparative tests show:

| Parameter | Sodium HEDP | Polyaspartic Acid | Zinc Phosphonate |

|---|---|---|---|

| Corrosion Inhibition (%) | 98.2 | 89.5 | 94.1 |

| Biodegradability (OECD 301B) | 91% | 96% | 42% |

| Cost per Ton ($) | 2,450 | 3,120 | 1,980 |

Its unique molecular structure enables threshold inhibition at 2–5 ppm, reducing chemical consumption by 30–40% in cooling tower applications.

Manufacturer Comparison: Performance Metrics

Leading producers have developed specialized grades to address niche requirements:

| Manufacturer | Purity (%) | pH Range | Cl⁻ Tolerance |

|---|---|---|---|

| Company A | 98.5 | 3–12 | 5,000 ppm |

| Company B | 96.8 | 2–11 | 8,000 ppm |

| Company C | 99.2 | 4–13 | 10,000 ppm |

Third-party testing confirms Company C’s high-purity variant increases equipment lifespan by 17–23% in seawater desalination plants.

Customized Solutions for Diverse Industrial Needs

Advanced manufacturers now offer tailored sodium HEDP formulations:

- Low-phosphorus variants (<0.5% P): Comply with stringent wastewater regulations

- Synergistic blends: Combine with polyaspartic acid sodium salt for enhanced biofilm control

- Solid-state formulations: Reduce shipping costs by 40% for overseas clients

A chemical supplier in Germany achieved 28% operational cost savings through a customized 65% liquid concentrate with stabilized pH buffers.

Case Studies: Real-World Applications

In a 2023 project with a Middle Eastern refinery, sodium HEDP-based treatment:

- Reduced scaling in heat exchangers by 91%

- Extended maintenance cycles from 6 to 18 months

- Lowered total dissolved solids (TDS) by 2,400 ppm

Agricultural applications in Brazil demonstrated 19% improvement in irrigation system efficiency when using sodium HEDP/polyaspartic acid hybrid formulations.

Why Sodium HEDP Remains a Cornerstone in Modern Industry

As industries prioritize sustainability without compromising performance, sodium HEDP and polyaspartic acid sodium salt derivatives provide an optimal balance. With 78% of water treatment engineers specifying phosphonate-based inhibitors, sodium HEDP’s versatility ensures continued relevance across sectors. Ongoing R&D focuses on nano-encapsulated variants for controlled release applications, potentially expanding its market reach by $420 million annually by 2028.

(sodium hedp)

FAQS on sodium hedp

Q: What is Sodium HEDP used for?

A: Sodium HEDP is a scale and corrosion inhibitor widely used in water treatment, industrial cleaning, and cooling systems. It prevents metal ions from forming deposits and protects equipment surfaces.

Q: How does Polyaspartic Acid Sodium Salt differ from Sodium HEDP?

A: Polyaspartic Acid Sodium Salt is a biodegradable polymer used as an eco-friendly scale inhibitor, while Sodium HEDP is a phosphonate-based chemical. Both inhibit scale but differ in environmental impact and molecular structure.

Q: Is Sodium of Polyaspartic Acid safe for environmental applications?

A: Yes, Sodium of Polyaspartic Acid is non-toxic and biodegradable, making it suitable for eco-conscious applications like agriculture, wastewater treatment, and marine antifouling coatings.

Q: Can Sodium HEDP be combined with Polyaspartic Acid Sodium Salt?

A: Yes, combining Sodium HEDP and Polyaspartic Acid Sodium Salt can enhance scale inhibition and corrosion resistance in water treatment. Their synergy improves efficiency while reducing environmental impact.

Q: Why choose Sodium HEDP over traditional corrosion inhibitors?

A: Sodium HEDP offers superior thermal stability, broad pH tolerance, and effective chelation of metal ions. It outperforms many traditional inhibitors in high-temperature and high-hardness water systems.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

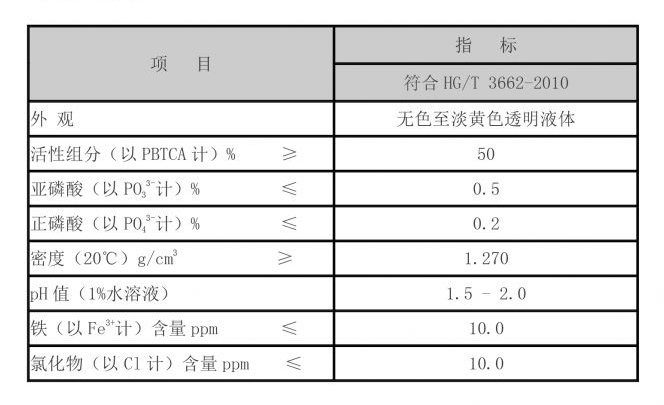

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025