Flocculant Production Facility for Efficient Water Treatment Solutions

The Emergence of Flocculant Factories A Key Player in Water Treatment

In an era where water scarcity and pollution are critical global issues, the need for effective water treatment solutions has never been more pressing. Flocculants, chemical agents that promote the clumping of particles to form flocs, are vital in the process of water purification. Flocculant factories have emerged as essential players in the production of these chemicals, contributing to cleaner water and a healthier environment.

Flocculants are utilized in various applications, ranging from wastewater treatment to the clarification of drinking water. They facilitate the removal of suspended solids, organic matter, and other impurities from water. As industries continue to grow, so does the demand for high-quality flocculants. The establishment of flocculant factories has become paramount to meet this demand efficiently.

A flocculant factory typically consists of several functional areas, including research and development (R&D), production, quality control, and logistics

. The R&D department is crucial for innovation, where scientists and engineers work to develop new formulations and improve existing products. They examine the interaction of flocculants with different types of wastewater, seeking ways to enhance their effectiveness while minimizing environmental impacts.The production process in a flocculant factory involves the synthesis of various chemical compounds, including polyacrylamides, natural polymers, and inorganic coagulants. Each type of flocculant has its unique properties and applications. For instance, polyacrylamide-based flocculants are widely used for their high efficiency in settling and clarifying particles. In contrast, natural polymer flocculants are favored for biodegradable applications, highlighting the trend towards more sustainable practices in the industry.

flocculant factory

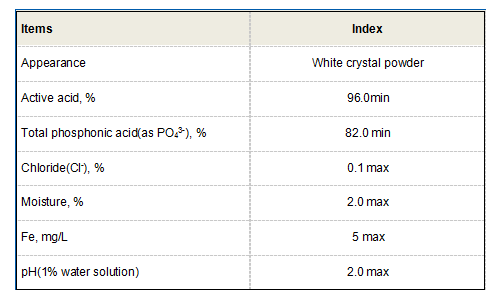

Quality control is integral to the operations of a flocculant factory. Ensuring that the produced flocculants conform to international standards is essential for their effectiveness and safety. Factories employ rigorous testing protocols to assess the properties of the flocculants, such as molecular weight, charge density, and solubility. These tests are crucial to guarantee that the products meet the specific requirements of various industries, including municipal water treatment, paper manufacturing, and mining.

Moreover, environmental considerations play a significant role in the operations of flocculant factories. As awareness of environmental issues grows, there is a mounting pressure for factories to adopt sustainable manufacturing practices. Many flocculant manufacturers are now focusing on reducing their ecological footprint by utilizing renewable resources, minimizing waste, and ensuring that their products are non-toxic and environmentally friendly.

The logistics aspect of flocculant factories is also vital. Efficient distribution channels ensure that flocculants reach their intended markets promptly. Given that water treatment is critical for public health and safety, timely delivery of flocculants to municipalities and industries is crucial. Factories often establish partnerships with reliable logistics providers to facilitate the transport of their products, ensuring that they can respond swiftly to market demands.

As global water challenges continue to escalate, the role of flocculant factories will likely expand. Innovative formulations that cater to specific water treatment needs will be developed, and increased emphasis will be placed on sustainability and environmental stewardship. Furthermore, collaboration between academia, industry, and government will be essential to advance research and development in this field.

In conclusion, flocculant factories are at the forefront of addressing the pressing challenges associated with water treatment. By producing effective and innovative flocculants, these factories play a critical role in ensuring access to clean water and promoting environmental sustainability. As the world continues to grapple with water scarcity and pollution, the importance of flocculant manufacturers will only increase, highlighting the need for continued investment and innovation in this vital sector. Through their efforts, flocculant factories contribute not only to improved water quality but also to the overall health and well-being of communities around the globe.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025