Effective Solutions for Water Treatment Using Scale Inhibitors to Prevent Mineral Build-Up

Scale Inhibitor Water Treatment Essential Solutions for Industrial Processes

Water is a vital resource in various industrial processes, but its quality often poses challenges due to the presence of minerals that can form scale. Scale, a hard, solid deposit, can accumulate in pipes, boilers, and cooling towers, leading to reduced efficiency, increased operational costs, and potential equipment failure. To combat these issues, scale inhibitors are essential in water treatment systems. This article explores the significance of scale inhibitors, their mechanisms, and their application in water treatment.

Understanding Scale and Its Impact

Scale primarily consists of calcium carbonate, calcium sulfate, barium sulfate, and other mineral deposits that precipitate when water is heated or evaporated. Industries such as power generation, oil and gas, and manufacturing are particularly vulnerable to scaling due to the high temperatures and pressures involved in their processes. The formation of scale can lead to a variety of problems, including

1. Reduced Heat Transfer Efficiency Scale acts as an insulating layer, decreasing the efficiency of heat exchangers and boilers, leading to higher energy consumption. 2. Increased Maintenance Costs Accumulated scale requires frequent cleaning and maintenance, which can be costly and time-consuming.

3. Equipment Damage Severe scaling can cause blockages or corrosion, potentially resulting in catastrophic equipment failures.

Given these implications, implementing effective water treatment solutions is crucial for maintaining operational efficiency and reducing costs.

The Role of Scale Inhibitors

Scale inhibitors are chemicals designed to prevent the formation and deposition of scale in water. They work through several mechanisms, including

1. Threshold Inhibition These inhibitors allow minerals to remain in a dissolved state longer than they normally would, preventing crystallization and scale formation.

scale inhibitor water treatment

3. Dispersion They assist in keeping small particles suspended in the water, preventing them from aggregating and forming larger deposits.

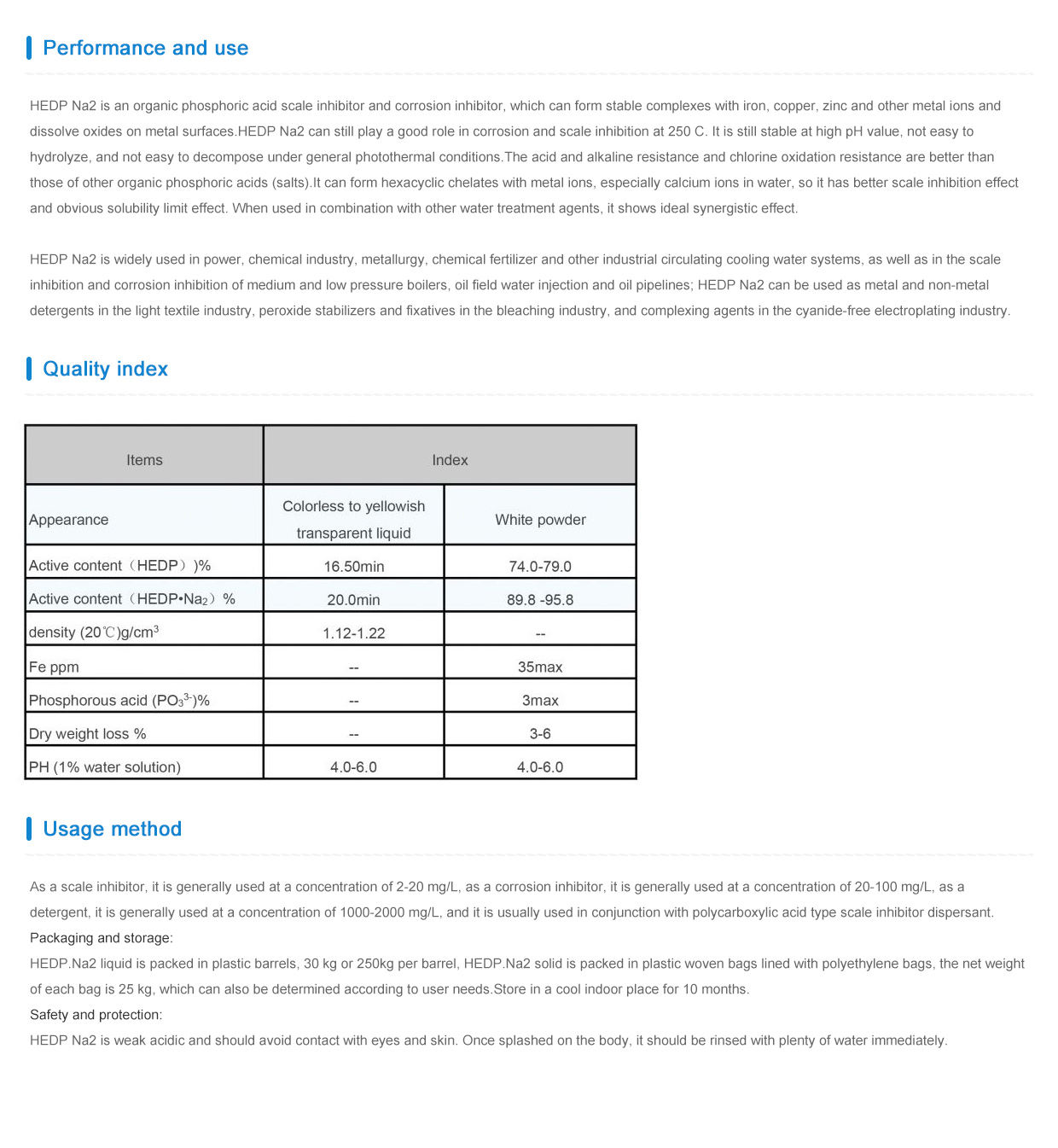

Common scale inhibitors include phosphonates, polycarboxylates, and organic acids. Each has its own unique properties and is selected based on the specific requirements of the water system.

Applications of Scale Inhibitors in Water Treatment

The use of scale inhibitors is widespread across various industries

1. Power Generation In power plants, water is heated to produce steam. The presence of scale can significantly hinder heat transfer, making scale inhibitors essential to maintaining efficiency. Additionally, they help reduce the frequency of cleaning and maintenance interventions.

2. Oil and Gas Industry Scale formation is prevalent in oil extraction due to the mix of water and hydrocarbons. Inhibitors play a critical role in oil recovery and during the processing of produced water, preventing scale that can clog pipelines and equipment.

3. Cooling Systems In cooling towers and chillers, scale can deposit on heat exchange surfaces, reducing heat transfer efficiency. The application of scale inhibitors helps maintain optimal performance and prolongs equipment life.

4. Manufacturing Processes Many manufacturing processes that require water for cooling or as a component in products are at risk for scaling. Using scale inhibitors ensures consistent product quality and reduces downtime due to maintenance.

Conclusion

Scale inhibitors are a vital component of water treatment systems across multiple industries. Their ability to prevent the formation of scale not only enhances the efficiency of industrial processes but also extends the lifespan of equipment while minimizing maintenance costs. As industries continue to tackle water quality challenges, the demand for effective scale inhibitors is likely to grow. Organizations must invest in comprehensive water treatment solutions, incorporating advanced scale inhibition technologies to safeguard their operations and promote sustainability. By addressing scaling challenges proactively, industries can improve operational efficiency and reduce the environmental footprint associated with excessive water use and treatment inefficiencies.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025