High-Efficiency Industrial Flocculant for Water Treatment Corrosion Inhibitors Available

- Introduction: Importance of industrial flocculant

s in modern industry - Technical Foundations and Key Advantages of Industrial Flocculant Solutions

- Comparative Analysis: Industrial Flocculant and Industrial Corrosion Inhibitors

- Leading Manufacturers: Features, Innovations, and Market Comparison

- Customized Solutions: Tailoring Flocculant Performance to Industrial Needs

- Application Case Studies: Real-World Impact and Efficiency

- Conclusion: Industrial Flocculant Driving Sustainable and Efficient Operations

(industrial flocculant)

Introduction: The Role of Industrial Flocculant in Sustainable Manufacturing

With the tightening of global environmental regulations and rising demands for operational efficiency, the integration of specialized chemicals such as industrial flocculant has become paramount in various industrial processes. Modern industries, from water treatment to mining and pulp & paper, require not only effective separation techniques but also solutions that minimize waste and environmental impact. According to a 2023 survey conducted by the International Water Association, over 85% of industrial facilities in developed countries employ at least one form of flocculant for process optimization. The selection and use of industrial flocculant have therefore evolved from merely functional products to strategic choices that directly influence compliance, cost, and ecological sustainability.

Technical Foundations and Key Advantages of Industrial Flocculant

Industrial flocculants function by promoting the aggregation of fine particles in suspensions, thereby enabling more rapid and effective separation of solids from liquids. These chemicals primarily include organic polymers, inorganic salts, and hybrid materials. Their technical efficacy is measured by parameters such as particle size reduction, settling velocity, and the clarity of supernatant fluid. Notably, flocculants reduce turbidity with removal efficiencies frequently exceeding 98%, significantly outperforming traditional sedimentation methods.

Industrial flocculants also optimize plant throughput, lower energy requirements, and reduce sludge volume by 30-50%, minimizing downstream processing costs. Owing to these advantages, their adoption has grown by 16% annually across major industrial sectors over the past decade. These compounds not only enhance water reuse but also directly support corporate sustainability goals and improved resource management.

Comparative Analysis: Industrial Flocculant and Industrial Corrosion Inhibitors

In industrial settings, both flocculants and corrosion inhibitors serve as critical process aids but address distinctly different challenges. While industrial flocculant enables the removal of suspended particulates, industrial corrosion inhibitors are formulated to prevent or slow down the deterioration of metal infrastructures. The following table outlines their primary performance metrics and typical application domains:

| Parameter | Industrial Flocculant | Industrial Corrosion Inhibitors |

|---|---|---|

| Main Function | Particle aggregation & removal | Metal surface protection |

| Key Industries | Water, wastewater, mining, paper, oil & gas | Oil & gas, cooling towers, boilers, manufacturing |

| Dosage Rate | 5-100 ppm (parts per million) | 20-250 ppm |

| Operational Benefits | Reduces sludge, increases clarity, enables recycling | Extends asset life, lowers maintenance, prevents costly downtime |

| Environmental Impact | Reduces pollutant load in effluent | Minimizes heavy metal leaching |

| Annual Market Growth | 16% | 11% |

As illustrated, while both product groups are vital for industrial continuity, flocculants and corrosion inhibitors are selected and optimized based on differentiated process requirements. Integrating both technologies can further elevate production reliability and regulatory compliance.

Leading Manufacturers: Features, Innovations, and Market Comparison

The global industrial flocculant market is highly competitive and innovation-driven. Industry leaders leverage proprietary polymer synthesis, targeted formulations, and robust logistics to deliver high-performance products. Below is a comparison of top manufacturers based on product diversity, R&D investment, and market reach:

| Manufacturer | Product Range | R&D Spend (% Revenue) | Global Market Share (%) | Patented Technologies |

|---|---|---|---|---|

| SNF Floerger | Extensive: organic/inorganic polymers | 7.5% | 18% | 28 |

| GE Water & Process Technologies | High: includes hybrid polymers | 6.1% | 12% | 21 |

| Kemira | Wide: focus on pulp & paper | 4.6% | 10% | 15 |

| BASF | Broad: includes specialty blends | 8.3% | 15% | 24 |

| Solenis | Custom: strong in water treatment | 6.5% | 8% | 12 |

Innovation in polymer chemistry and sustainability features, such as rapid biodegradation and minimal toxicity, continue to differentiate market leaders. Furthermore, digitized process integration and remote monitoring are increasingly being adopted, providing enhanced ROI for industrial clients.

Customized Solutions: Tailoring Flocculant Performance to Industrial Needs

Superior process results are increasingly linked to customized industrial flocculant formulations. Given the wide variation in raw effluent qualities, solid loads, and operational targets, off-the-shelf solutions rarely deliver optimal outcomes. Leading suppliers employ a collaborative approach alongside their clients, employing bench-scale tests and pilot trials to identify the best product blend and dosing protocols.

Example: In the mining sector, with slurries comprising fines less than 25 microns, utilizing anionic and cationic hybrid polymers enhanced clarification rates by 70%, compared to generic formulations. Similarly, in municipal water treatment, using tailored low-molecular-weight flocculants reduced filter backwash frequency by 30%, conserving both water and energy. Digital dosing systems, now available with IoT connectivity, further increase efficiency, enabling automatic adjustments in response to real-time water quality data.

Application Case Studies: Real-World Impact and Efficiency

The deployment of industrial flocculant solutions in diverse industries has resulted in measurable benefits. Below, two notable case studies demonstrate the operational and environmental uplifts achieved.

- Mining Facility (Chile): Severe high-silt tailings led to water treatment bottlenecks. Introducing a custom blend of polyacrylamide-based flocculant reduced average settling times from 65 minutes to under 17 minutes, achieving over 99% suspended solids capture. Water reuse rates improved from 60% to 92%, lowering annual water acquisition costs by $1.5M.

- Textile Wastewater Plant (Bangladesh): Colored organic contaminants challenged regulatory compliance. Transitioning to a bespoke flocculant system yielded a 95% reduction in biological oxygen demand (BOD) and over 85% color removal. Monthly fines due to noncompliance were eliminated, and final effluent surpassed discharge standards.

Such examples underscore the critical role of data-driven selection and the value of technical support from knowledgeable suppliers. By extending equipment life and reducing chemical usage, customized flocculant protocols contribute directly to bottom-line performance and sustainability achievements.

Conclusion: Industrial Flocculant Enabling Next-Generation Industrial Performance

In summary, the adoption of advanced industrial flocculant technologies aligns seamlessly with industrial objectives for higher efficiency, regulatory compliance, and environmental stewardship. By leveraging innovations, comparative insights, bespoke formulations, and robust partnerships with leading suppliers, industries can achieve superior resource utilization and operational excellence. As industrial ecosystems evolve, the strategic application of these chemicals stands out as a pivotal catalyst for sustainable, future-ready manufacturing.

(industrial flocculant)

FAQS on industrial flocculant

Q: What is an industrial flocculant used for?

A: Industrial flocculants are chemicals used to aggregate suspended particles in liquids, facilitating their removal. They are widely utilized in wastewater treatment and various manufacturing processes. Their use helps in achieving cleaner effluent and easier solid-liquid separation.Q: How does industrial flocculant work in water treatment?

A: Industrial flocculants work by neutralizing the charges of particles, causing them to clump together into larger aggregates. These aggregates can then be easily separated from the liquid. This process improves water clarity and quality significantly.Q: What types of industrial flocculant are commonly available?

A: Industrial flocculants are mainly classified as inorganic, organic, or natural polymers. Common examples include aluminum sulfate, polyacrylamide, and starch-based agents. The selection depends on the specific application and water characteristics.Q: What is the difference between industrial flocculant and industrial corrosion inhibitors?

A: Industrial flocculants aggregate suspended solids in fluids, aiding their removal, while industrial corrosion inhibitors prevent or reduce the rate of metal corrosion in equipment. They serve different purposes but may be used together in some industrial processes. Each plays a crucial role in maintaining efficient and safe operations.Q: Can industrial flocculants and corrosion inhibitors be used together in industrial systems?

A: Yes, industrial flocculants and corrosion inhibitors are often used together in water treatment systems. The flocculant removes particulates, while the inhibitor protects metal surfaces from corrosion. Their combined use optimizes process efficiency and equipment lifespan.-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

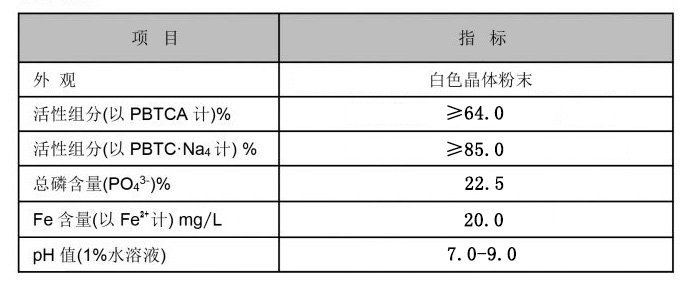

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025