High-Performance Polyacrylamide for OEM Applications and Industrial Uses

Understanding OEM Polyacrylamide Uses, Benefits, and Applications

Polyacrylamide (PAM) is a versatile synthetic polymer that has gained prominence in various industries due to its excellent properties, including water solubility, high molecular weight, and the ability to form gels. As industries look for customization and tailored solutions for their specific needs, Original Equipment Manufacturer (OEM) polyacrylamide has emerged as a significant player in the market. This article explores what OEM polyacrylamide is, its benefits, and its wide-ranging applications.

What is OEM Polyacrylamide?

OEM polyacrylamide refers to polyacrylamide that is manufactured according to the specifications and requirements of a particular client or industry. This means that the product can be customized in terms of molecular weight, degree of hydrolysis, and composition to suit specific applications. The OEM approach allows companies to leverage the advantages of polyacrylamide while ensuring that the end product aligns with their unique operational needs.

Benefits of OEM Polyacrylamide

1. Customization One of the most significant advantages of OEM polyacrylamide is its customizability. By working with manufacturers, businesses can specify the exact properties they need—whether it’s a particular viscosity, solubility level, or interaction with other chemicals.

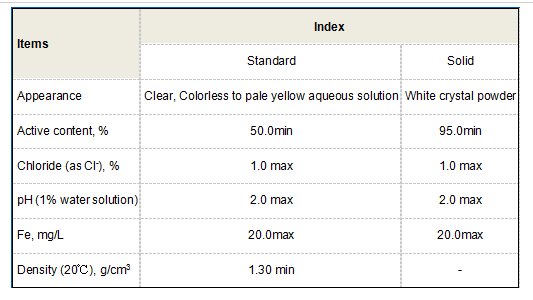

2. Quality Control OEM manufacturers often adhere to rigorous quality control standards. This ensures that the polyacrylamide produced meets specific quality, safety, and performance criteria, reducing the risk of product failure or inconsistency in applications.

3. Cost-Effectiveness By customizing their polymer needs, companies can optimize their production processes, resulting in cost savings. Customized solutions can lead to improved performance and efficiency, reducing waste and enhancing productivity.

4. Innovation OEM partnerships often foster innovation. Manufacturers are equipped to collaborate on the development of new formulations that can enhance product performance, tackling industry-specific challenges more effectively.

oem polyacrylamide

Applications of OEM Polyacrylamide

The applications of OEM polyacrylamide span a broad spectrum of industries

1. Water Treatment One of the most prominent uses of polyacrylamide is in the water treatment sector. It is commonly used as a flocculant, helping to remove suspended particles from water, thus improving clarity and quality. OEM formulations can be tailored to optimize performance under various environmental conditions.

2. Oil Recovery In the oil and gas industry, polyacrylamide is utilized in Enhanced Oil Recovery (EOR) techniques. It helps to increase the efficiency of oil extraction by altering the viscosity of drilling fluids and promoting the displacement of oil from the reservoir.

3. Agriculture Polyacrylamide is used in agriculture to improve soil structure and moisture retention. OEM formulations can be designed to enhance specific soil types or crops, promoting better yield and resource efficiency.

4. Mining and Mineral Processing In the mining industry, polyacrylamide is often employed in the separation of minerals. Customized formulations can improve the efficiency of mineral recovery processes, making them more cost-effective and environmentally friendly.

5. Cosmetics and Personal Care The cosmetic industry also benefits from OEM polyacrylamide. Its gel-forming properties make it a popular ingredient in various beauty products, including lotions and creams.

Conclusion

OEM polyacrylamide presents a remarkable opportunity for industries seeking customized solutions that meet their specific needs. By leveraging the benefits of customization, quality control, cost-effectiveness, and innovation, companies can enhance their operations and product performance. Whether in water treatment, oil recovery, agriculture, mining, or cosmetics, the tailored applications of OEM polyacrylamide demonstrate its versatility and importance in modern industrial processes. As industries continue to evolve, the demand for specialized solutions like OEM polyacrylamide is expected to grow, paving the way for further innovation and sustainability in various sectors.

-

LK-319 Special Scale And Corrosion Inhibitor For Steel Plants: Advanced Solutions for Industrial Water SystemsNewsAug.22,2025

-

Flocculant Water Treatment: Essential Chemical Solutions for Purification ProcessesNewsAug.22,2025

-

Isothiazolinones: Versatile Microbial Control Agents for Industrial and Consumer ApplicationsNewsAug.22,2025

-

Scale Inhibitor: Key Solutions for Water System Scale PreventionNewsAug.22,2025

-

Organophosphonates: Versatile Scale Inhibitors for Industrial Water SystemsNewsAug.22,2025

-

Scale and Corrosion Inhibitor: Essential Chemical Solutions for Water System MaintenanceNewsAug.22,2025