cooling tower scale inhibitor

The Importance of Cooling Tower Scale Inhibitors

Cooling towers play a vital role in various industrial processes, providing essential cooling for equipment and maintaining optimal operational efficiency. However, the accumulation of scale within these systems can lead to significant challenges, affecting performance and increasing operational costs. This is where cooling tower scale inhibitors become essential.

Scale formation in cooling towers primarily occurs due to the evaporation of water, which concentrates minerals like calcium, magnesium, and silica. As these minerals precipitate, they form hard deposits that can clog pipes, reduce heat exchange efficiency, and ultimately lead to equipment failure. To mitigate these issues, the use of scale inhibitors is an effective solution.

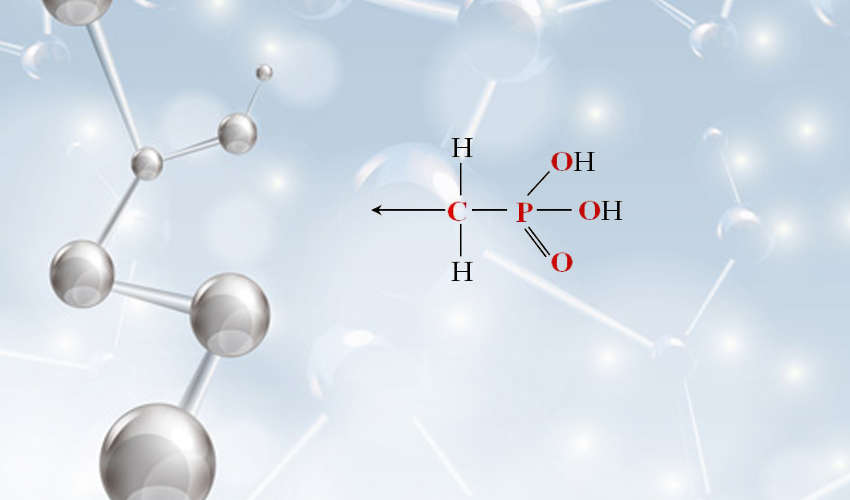

Cooling tower scale inhibitors work by interfering with the crystallization process of scale-forming minerals. They can be categorized into several types, including threshold inhibitors, dispersants, and crystal modifiers. Threshold inhibitors prevent the formation of scale at low concentrations, while dispersants keep existing particles suspended in water, preventing them from adhering to surfaces. Crystal modifiers change the growth habits of scale crystals, making them less likely to form deposits.

cooling tower scale inhibitor

The application of scale inhibitors not only enhances the reliability and efficiency of cooling towers but also reduces maintenance costs. By minimizing scale buildup, operators can extend the life of their equipment and avoid costly downtime associated with scale-related failures. Additionally, maintaining optimal heat exchange efficiency can lead to lower energy consumption and reduced environmental impact, aligning with modern sustainability goals.

It’s important to carefully select the appropriate scale inhibitor based on water chemistry and system conditions. Factors such as pH, temperature, and the specific minerals present in the water should be taken into consideration. Regular monitoring and precise dosing of inhibitors are crucial to achieving optimal results and ensuring long-term protection against scale.

In conclusion, cooling tower scale inhibitors are essential for maintaining the operational efficiency of cooling systems. By preventing scale formation, they protect equipment, reduce maintenance costs, and contribute to more sustainable industrial practices. For businesses relying on cooling towers, investing in high-quality scale inhibitors is not just a preventive measure but a strategic move towards operational excellence and sustainability.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025