polyacrylamide manufacturers

Polyacrylamide Manufacturers An Overview of the Industry

Polyacrylamide, a versatile polymer, has gained significant attention in various industries, including wastewater treatment, agriculture, oil recovery, and the paper manufacturing sector. As its demand continues to grow, the role of polyacrylamide manufacturers becomes increasingly vital. This article explores the landscape of polyacrylamide manufacturing, including its applications, production processes, challenges, and future trends.

Understanding Polyacrylamide

Polyacrylamide (PAM) is a synthetic polymer formed through the polymerization of acrylamide monomers. It exists in various forms, such as anionic, cationic, and nonionic, depending on the charge of the polymer chains. The distinct properties of polyacrylamide enable it to serve unique functions across different applications. Its high molecular weight and ability to absorb water make it an effective agent in flocculation, which is crucial in separating solids and liquids in industrial processes.

Applications of Polyacrylamide

1. Water Treatment One of the most prominent uses of polyacrylamide is in wastewater treatment. It acts as a coagulant and flocculant, helping to remove contaminants from water. By facilitating the aggregation of suspended particles into larger clusters, polyacrylamide enhances sedimentation and filtration processes.

2. Agriculture Polyacrylamide also finds extensive use in agriculture as a soil conditioner. It improves water retention in arid regions, reduces soil erosion, and enhances crop yield. By forming a gel-like structure in the soil, it helps in retaining moisture, making it ideal for irrigation practices.

3. Oil Recovery In the oil and gas industry, polyacrylamide is employed in enhanced oil recovery (EOR) techniques. It improves the viscosity of water injected into oil reservoirs, which helps in mobilizing trapped oil. This method is particularly beneficial in mature oil fields, leading to increased extraction efficiencies.

4. Paper Manufacturing The paper industry utilizes polyacrylamide as a retention aid and drainage aid, which helps in the efficient use of raw materials and enhances the quality of the final product.

The Production Process

The manufacturing of polyacrylamide involves several key steps

polyacrylamide manufacturers

1. Synthesis Acrylic acid and acrylamide are the primary raw materials. These are polymerized through a free-radical process, either in an aqueous solution or in a solid-state process.

2. Purification Once synthesized, the product must be purified to remove residual monomers that could be toxic. Various methods, such as recrystallization or alcohol precipitation, are employed to achieve this.

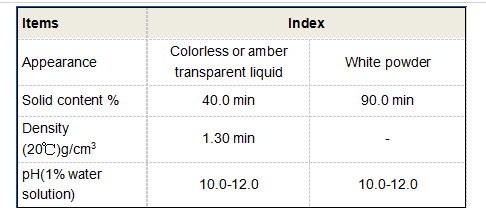

3. Drying and Formulation The purified polyacrylamide is then dried and formulated into various grades, such as powder or emulsion forms, based on its intended applications. Each grade has its specific characteristics tailored for different industrial needs.

Challenges Faced by Manufacturers

Despite the growing demand for polyacrylamide, manufacturers face several challenges

1. Environmental Concerns There are increasing concerns about the environmental impact of polyacrylamide, especially its potential toxicity. The industry must find ways to mitigate risks associated with its use and disposal.

2. Regulatory Compliance Stricter regulations governing chemical manufacturing and usage are emerging globally. Manufacturers must stay informed and compliant with these regulations to operate legally and sustainably.

3. Market Competition As the demand for polyacrylamide rises, so does competition among manufacturers. Companies must innovate and improve their production processes to maintain a competitive edge, often necessitating significant investment in research and development.

Future Trends

Looking ahead, the polyacrylamide industry is poised for growth. With advancements in technology and an increased focus on sustainable practices, manufacturers are exploring eco-friendly alternatives and biodegradable options. Moreover, the rising emphasis on water purification and agricultural efficiency will likely drive demand for polyacrylamide.

In conclusion, polyacrylamide manufacturers play an essential role in addressing various industrial needs. By understanding the applications, production processes, and challenges associated with polyacrylamide, these manufacturers can better position themselves for success in a rapidly evolving market. As the industry adapts to emerging trends and continues to innovate, the future of polyacrylamide looks promising, contributing significantly to several key sectors worldwide.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025