corrosion & scale inhibitors

Corrosion and Scale Inhibitors Essential Solutions for Asset Protection

Corrosion, the gradual destruction of materials by electrochemical reaction with their environment, poses significant challenges across various industries, including oil and gas, water treatment, and manufacturing. In conjunction with corrosion, the formation of scale—mineral deposits that develop on surfaces in contact with water—can lead to operational inefficiencies and equipment failure. To mitigate these issues, corrosion and scale inhibitors are employed as vital agents to protect assets, enhance efficiency, and extend the lifespan of industrial systems.

Understanding Corrosion and Scale

Before delving into the specifics of inhibitors, it is important to grasp the complexities of corrosion and scale formation. Corrosion can occur through several mechanisms, including uniform corrosion, pitting, galvanic corrosion, and stress corrosion cracking. Factors such as moisture, temperature, and the presence of specific chemicals in the environment can accelerate these processes.

Scale formation, on the other hand, typically arises from dissolved minerals in water, such as calcium, magnesium, and silica. When water is heated or evaporated, these minerals precipitate out of solution and form hard deposits. This scale accumulation can impede heat transfer, reduce flow rates, and necessitate costly maintenance interventions.

The Role of Inhibitors

Corrosion and scale inhibitors serve as protective measures to combat the deterioration of materials and the unwanted buildup of deposits

. They can be categorized into several types based on their mechanisms and application methods.1. Corrosion Inhibitors These compounds can either be anodic or cathodic inhibitors. Anodic inhibitors form a protective oxide layer on the metal surface, while cathodic inhibitors restrict the flow of electrons to the metal. Common examples include phosphates, nitrates, and chromium compounds. In oil and gas applications, amine-based inhibitors are frequently utilized for their effectiveness in corrosive environments.

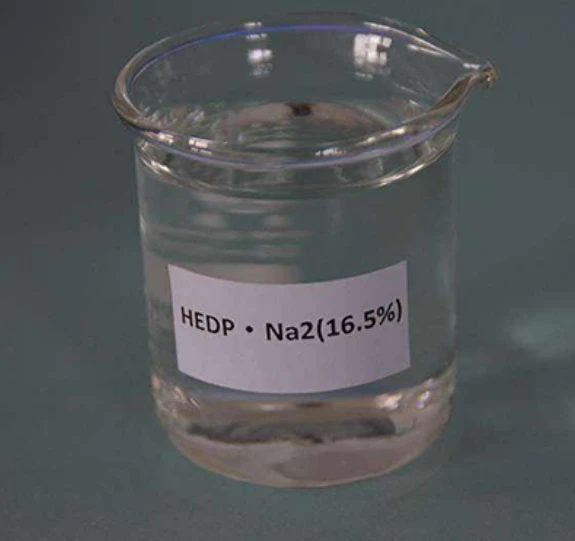

2. Scale Inhibitors These chemicals modify the crystallization process of mineral deposits, preventing them from adhering to surfaces. Phosphonates, polyacrylic acids, and various organic polymers are among the most commonly used scale inhibitors. They function by either dispersing particles in suspension or altering the crystal structure, thus reducing the propensity for scale formation.

corrosion & scale inhibitors

Application and Benefits

The application of corrosion and scale inhibitors is crucial for optimizing operational efficiency and preserving equipment integrity. In the water treatment industry, for instance, the use of these inhibitors can significantly reduce maintenance costs associated with cleaning and repairing scale-affected systems. Moreover, in industries such as power generation and petrochemicals, the prevention of corrosion leads to minimized downtime and improved safety by reducing the risk of leaks and failures.

Furthermore, the use of these inhibitors can support sustainability efforts. By extending the lifespan of infrastructure and reducing resource consumption for repairs and replacements, organizations can lower their environmental impact.

Challenges and Future Directions

Despite their benefits, the selection and application of corrosion and scale inhibitors are not without challenges. The effectiveness of these inhibitors can be influenced by factors such as temperature fluctuations, fluid composition, and flow rates. Therefore, a thorough understanding of the specific operational environment is essential for optimizing inhibitor performance.

Emerging trends in the development of corrosion and scale inhibitors include the exploration of green chemistry alternatives. There is a growing interest in bio-based inhibitors derived from natural sources, which may offer environmentally friendly options without compromising performance. Additionally, the integration of smart materials and sensors could pave the way for real-time monitoring and adaptive responses to corrosion and scale threats.

Conclusion

In conclusion, corrosion and scale inhibitors play a critical role in protecting industrial assets and maintaining operational efficiency. By understanding their mechanisms and applications, industries can effectively combat the detrimental effects of corrosion and scale, ultimately enhancing sustainability and reducing costs. As research progresses, the industry can expect innovative solutions that further push the boundaries of asset protection, leading to safer and more resilient infrastructures.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025