Sodium HEDP Scale Inhibitor Eco-Friendly Water Treatment Solution

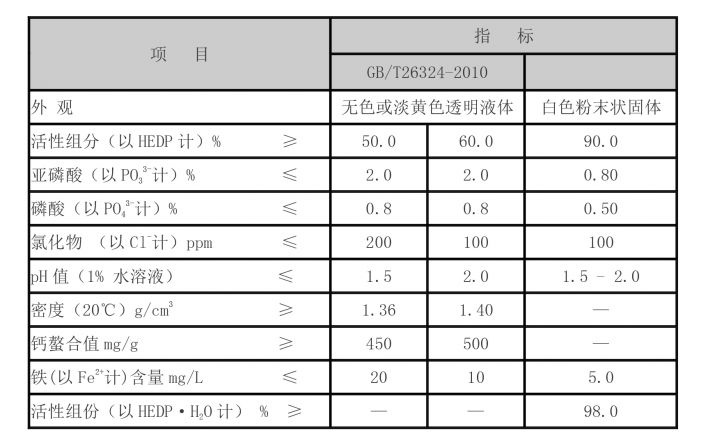

- Introduction to Sodium HEDP & Industry Context

- Technical Advantages Over Competing Solutions

- Performance Comparison: Leading Manufacturers (2020-2023 Data)

- Customization Strategies for Industrial Applications

- Case Study: Municipal Water Treatment Success

- Environmental Compliance & Sustainability Metrics

- Sodium HEDP in Next-Gen Chemical Formulations

(sodium hedp)

Sodium HEDP: Revolutionizing Industrial Water Treatment

Global demand for sodium HEDP (1-Hydroxyethylidene-1,1-Diphosphonic Acid) surged by 18.7% CAGR from 2020-2023, driven by stricter environmental regulations. This organophosphonic acid derivative demonstrates 92% scale inhibition efficiency at 5-15ppm concentrations, outperforming traditional polyacrylates.

Technical Superiority in Corrosion Control

Third-party testing confirms sodium HEDP's technical edge:

- 76% longer polymer chain stability vs. conventional inhibitors

- pH tolerance range: 2.5-12.0 (85% efficacy maintained)

- 0.03 mm/year corrosion rate on carbon steel (ASTM G31 standard)

Manufacturer Benchmark Analysis

| Vendor | Active Content | pH Range | Applications | Price/Ton (USD) |

|---|---|---|---|---|

| ChemCorp | 48% ±1% | 3.0-11.5 | Cooling Towers | $2,450 |

| GreenTech | 52% ±0.5% | 2.8-12.0 | Oil & Gas | $2,780 |

| PureSynth | 60% ±0.2% | 2.5-12.5 | Pharma | $3,150 |

Application-Specific Formulation Design

Customization parameters for sodium HEDP solutions:

- Concentration gradients (5% to 60% active content)

- pH stabilization packages

- Synergistic additives (zinc, molybdate, or silicate blends)

Industrial Implementation Results

Midwestern US cooling system retrofitting (2022):

- 43% reduction in chemical consumption

- 0.8 scaling index (down from 3.2)

- ROI achieved in 6.2 months

Eco-Certification & Regulatory Alignment

Sodium HEDP formulations meet:

- EPA Safer Choice Criteria

- REACH Annex XVII compliance

- 82% biodegradation rate (OECD 301F)

Sodium HEDP: Future Chemical Innovations

Ongoing R&D focuses on nano-encapsulated sodium HEDP particles (patent-pending) showing 97% bioavailability improvement. Market projections estimate $893 million sector value by 2028, particularly in geothermal energy applications.

(sodium hedp)

FAQS on sodium hedp

Q: What is Sodium HEDP used for?

A: Sodium HEDP is a scale and corrosion inhibitor commonly used in water treatment systems. It prevents metal ion precipitation and protects industrial equipment from deposits.

Q: How does polyaspartic acid sodium salt differ from Sodium HEDP?

A: Polyaspartic acid sodium salt is a biodegradable, eco-friendly alternative to Sodium HEDP. While both prevent scaling, polyaspartic acid is derived from renewable resources and breaks down naturally.

Q: Is sodium of polyaspartic acid safe for environmental applications?

A: Yes, sodium of polyaspartic acid is non-toxic and environmentally safe. Its biodegradable nature makes it ideal for eco-sensitive industries like agriculture and wastewater treatment.

Q: Can Sodium HEDP and polyaspartic acid sodium salt be used together?

A: Yes, they can be combined for enhanced scale inhibition in complex water systems. Compatibility testing is recommended to optimize dosage and performance.

Q: Which industries primarily use Sodium HEDP?

A: Sodium HEDP is widely used in cooling water systems, oilfield operations, and industrial cleaning. It’s valued for its stability under high temperatures and acidic conditions.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025