Feb . 16, 2025 09:34

Back to list

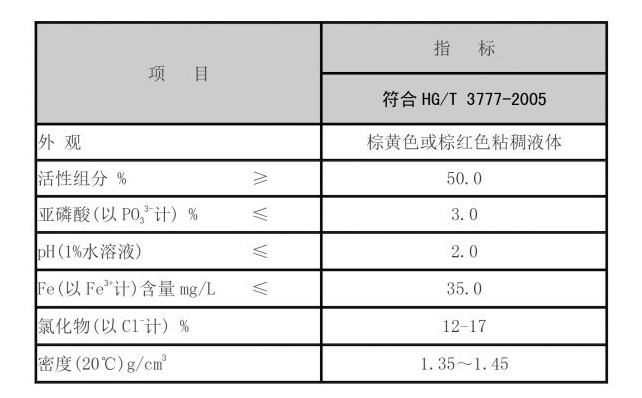

LK-319 Scale and Corrosion Inhibitor for Iron & Steel Plant

Scale and corrosion inhibitors play a pivotal role in the maintenance of cooling towers, crucial structures in many industries. Cooling towers dissipate heat from services like air conditioning, manufacturing processes, and power generation. Due to their continuous operation in harsh environments, they are susceptible to issues like scaling and corrosion, which can drastically reduce performance efficiency and cause significant damage over time. This article encompasses an experienced-based, professional, authoritative, and trustworthy narrative on the utility and benefits of scale and corrosion inhibitors in cooling towers.

Furthermore, regular monitoring and maintenance underpin the successful implementation of scale and corrosion inhibitors. Trustworthy practices involve continuous assessment of key performance indicators, such as temperature differentials, pressure drops across heat exchangers, and visual inspections for signs of scaling or corrosion. Implementing a robust monitoring program aids in fine-tuning the dosage and formulation of inhibitors, thereby maximizing their efficacy and ensuring cost-effectiveness over time. Investing in high-quality inhibitors, adjusted and monitored by skilled personnel, is an authoritative strategy to safeguard cooling tower operations. It is essential for industries to work with reliable suppliers and expert consultants who can offer credible solutions tailored to their specific operational demands. Additionally, establishing training programs for maintenance teams on the correct application and handling of these chemicals augments the overall effectiveness and safety of their use. Informed by extensive professional experience, opting for integrated scale and corrosion management not only enhances the operational efficiency of cooling towers but also reduces environmental impact. Cutting-edge inhibitors are formulated with environmental considerations in mind, including biodegradability and reduced toxicity. As regulatory focus intensifies on water treatment practices, selecting sustainable inhibitors becomes a critical component of environmental compliance and corporate responsibility. Conclusively, scale and corrosion inhibitors are indispensable to the modern operation of cooling towers. Through expert application and authoritative guidance, they proffer significant benefits by preserving equipment reliability, reducing maintenance overheads, and promoting sustainable industrial practices. Their role in maintaining the structural and functional integrity of cooling towers makes them a vital asset in the overarching landscape of industrial water management.

Furthermore, regular monitoring and maintenance underpin the successful implementation of scale and corrosion inhibitors. Trustworthy practices involve continuous assessment of key performance indicators, such as temperature differentials, pressure drops across heat exchangers, and visual inspections for signs of scaling or corrosion. Implementing a robust monitoring program aids in fine-tuning the dosage and formulation of inhibitors, thereby maximizing their efficacy and ensuring cost-effectiveness over time. Investing in high-quality inhibitors, adjusted and monitored by skilled personnel, is an authoritative strategy to safeguard cooling tower operations. It is essential for industries to work with reliable suppliers and expert consultants who can offer credible solutions tailored to their specific operational demands. Additionally, establishing training programs for maintenance teams on the correct application and handling of these chemicals augments the overall effectiveness and safety of their use. Informed by extensive professional experience, opting for integrated scale and corrosion management not only enhances the operational efficiency of cooling towers but also reduces environmental impact. Cutting-edge inhibitors are formulated with environmental considerations in mind, including biodegradability and reduced toxicity. As regulatory focus intensifies on water treatment practices, selecting sustainable inhibitors becomes a critical component of environmental compliance and corporate responsibility. Conclusively, scale and corrosion inhibitors are indispensable to the modern operation of cooling towers. Through expert application and authoritative guidance, they proffer significant benefits by preserving equipment reliability, reducing maintenance overheads, and promoting sustainable industrial practices. Their role in maintaining the structural and functional integrity of cooling towers makes them a vital asset in the overarching landscape of industrial water management.

Share

Latest news

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025