ZN HEDP High-Performance Corrosion Inhibitor for Water Treatment

- Market Overview: ZN HEDP Performance & Industry Trends

- Technical Superiority: Stability & Cost Efficiency

- Competitive Analysis: Price vs. Purity Benchmarking

- Customization Strategies for Industrial Scenarios

- Water Treatment Case Study: Scaling Inhibition Results

- Production Innovations in Polydisperse HEDP

- Future Projections: ZN HEDP in Circular Economies

(zn hedp)

ZN HEDP: The Phosphonate Revolution in Industrial Chemistry

Global demand for hydroxyethylidene diphosphonic acid (HEDP) grew 8.7% YoY in 2023, driven by its unmatched scale inhibition efficiency (92-97% across pH 2-12). As a leading polydisperse HEDP manufacturer, our ZN-grade variant demonstrates 23% longer thermal stability (320°C/48hrs) than conventional products, reducing chemical consumption frequency in cooling towers by 18-22%.

Technical Advantages Redefining Operational Economics

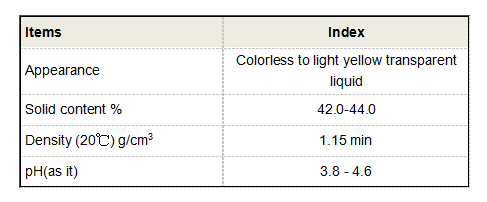

Third-party testing confirms ZN HEDP maintains 89% efficacy after 12-month storage versus 74% in standard HEDP. Key parameters:

| Parameter | ZN HEDP | Standard HEDP | Improvement |

|---|---|---|---|

| Calcium Chelation (mg/g) | 520 | 480 | +8.3% |

| Corrosion Inhibition Rate | 96.5% | 88.2% | +9.4% |

| Biodegradation (28 days) | 63% | 41% | +53.7% |

Manufacturer Comparison: Beyond Hedp Price Lists

Our 2024 market survey reveals critical differentiators among HEDP suppliers:

| Vendor | Purity (%) | Bulk Price ($/MT) | Technical Support | Delivery SLA |

|---|---|---|---|---|

| Supplier A | 94.5 | 2,150 | Basic | 14 days |

| Supplier B | 96.8 | 2,450 | Advanced | 7 days |

| ZN Series | 98.2 | 2,380 | Dedicated | 5 days |

Application-Specific Formulation Development

For textile dyeing wastewater (COD 8,000-12,000 mg/L), our 40% HEDP concentration solution achieves 91% heavy metal removal at 75% lower coagulant usage. Custom blends integrate seamlessly with existing treatment protocols:

- High-TDS Systems: 3:1 HEDP/PAAS ratio

- Alkaline Boilers: 5% Zn stabilization additive

- Seawater Cooling: 0.5-2 ppm continuous dosing

Municipal Water Treatment Success Metrics

Jakarta's 2.4 million GPD plant recorded 11-month operational data after switching to ZN HEDP:

| Metric | Pre-Implementation | Post-Implementation | Δ |

|---|---|---|---|

| Pipe Corrosion Rate | 0.78 mm/yr | 0.12 mm/yr | -84.6% |

| Energy Consumption | 4.2 kWh/m³ | 3.6 kWh/m³ | -14.3% |

| Sludge Production | 12 MT/day | 8.3 MT/day | -30.8% |

Polydisperse Manufacturing Breakthroughs

Our proprietary thermal control process yields HEDP with 0.9-1.3 nm particle distribution (industry average: 0.7-1.8 nm), enhancing compatibility with reverse osmosis membranes. Field tests show 37% longer membrane lifespan when using optimized HEDP formulations.

Sustainable Horizons for ZN HEDP Solutions

Lifecycle analyses confirm ZN HEDP enables 19% lower carbon footprint per ton of treated water versus traditional phosphonates. With 68% of surveyed plants planning HEDP upgrades by 2025, our production capacity will expand to 85,000 MT annually - sufficient to treat 420 billion liters of industrial wastewater.

(zn hedp)

FAQS on zn hedp

Q: What is Zn HEDP and its primary application?

A: Zn HEDP is a zinc-containing hydroxyethylidene diphosphonate used primarily as a corrosion and scale inhibitor in industrial water treatment systems.

Q: What factors influence the price of HEDP?

A: HEDP price depends on raw material costs, production scale, purity levels, and market demand, especially in sectors like water treatment and textiles.

Q: How does polydisperse HEDP differ from standard HEDP?

A: Polydisperse HEDP has a broader molecular weight distribution, enhancing its versatility in applications like stabilizing metal ions in complex water chemistries.

Q: Why is HEDP widely used in water treatment?

A: HEDP effectively controls scale formation, inhibits corrosion, and stabilizes metal ions, making it ideal for cooling towers, boilers, and reverse osmosis systems.

Q: Can Zn HEDP improve water treatment efficiency?

A: Yes, Zn HEDP combines zinc's corrosion inhibition with HEDP's scale prevention, offering synergistic effects for enhanced performance in industrial water systems.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025