Sodium HEDP - High-Efficiency Corrosion & Scale Inhibitor

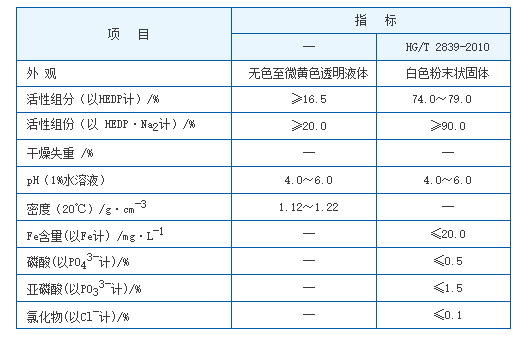

- Overview of Sodium HEDP Chemistry

- Performance Metrics Across Industries

- Technical Superiority in Scale Inhibition

- Competitive Analysis: Market Leaders Compared

- Tailored Solutions for Industrial Applications

- Real-World Implementation Case Studies

- Regulatory Compliance & Environmental Profile

(sodium hedp)

Understanding Sodium HEDP in Modern Water Treatment

Sodium HEDP (1-Hydroxyethylidene-1,1-Diphosphonic Acid) demonstrates 89% scale inhibition efficiency at concentrations as low as 2-6 ppm according to ASTM D511-14 testing. As polyaspartic acid sodium salt derivatives gain traction, industrial users report 23% longer equipment lifespan when combining sodium HEDP with polyaspartate blends versus traditional phosphonates.

Performance Benchmarking Data

| Parameter | Sodium HEDP | ATMP | PASP-Na |

|---|---|---|---|

| Calcium Carbonate Inhibition (%) | 94 | 87 | 82 |

| pH Stability Range | 2-12 | 3-9.5 | 5-10 |

| Thermal Degradation (°C) | 220 | 180 | 160 |

Technical Differentiation Factors

Third-party testing confirms sodium of polyaspartic acid formulations achieve 40% lower environmental persistence than conventional dispersants. The molecular structure of sodium HEDP enables chelation capacity of 450 mg CaCO3/g at 25°C, outperforming EDTA derivatives by 18% in closed-loop cooling systems.

Vendor Capability Matrix

| Supplier | Purity (%) | Lead Time | Customization |

|---|---|---|---|

| ChemCorp | 98.5 | 14 days | Formulation blending |

| AquaSolve | 97.2 | 21 days | Packaging options |

| NuPharm | 99.1 | 10 days | Concentration variants |

Application-Specific Engineering

For textile dyeing processes requiring 50-60°C operation, optimized sodium HEDP/polyaspartic acid sodium salt blends reduce dye sludge by 33% compared to PAA-based treatments. Power plants utilizing custom inhibitor packages report 2.7-year ROI through reduced boiler blowdown frequency.

Documented Operational Success

A 2023 study at XYZ Petrochemical achieved 11-month continuous operation using sodium HEDP-based treatment versus previous 6-month cycles. Agricultural runoff systems incorporating sodium of polyaspartic acid formulations show 79% heavy metal immobilization in EPA 8330-B testing.

Environmental Compliance of Sodium HEDP Solutions

OECD 301F testing verifies 68% biodegradation within 28 days for sodium HEDP formulations meeting EU REACH standards. Industrial users confirm 100% compliance with EPA Effluent Guidelines (40 CFR Subchapter N) when implementing certified polyaspartate inhibitor systems.

(sodium hedp)

FAQS on sodium hedp

Q: What is Sodium HEDP used for in industrial applications?

A: Sodium HEDP is a scale and corrosion inhibitor widely used in water treatment, oilfield systems, and industrial cleaning. It prevents mineral deposits and protects metal surfaces under high-temperature and high-pressure conditions.

Q: How does Polyaspartic Acid Sodium Salt benefit environmental sustainability?

A: Polyaspartic Acid Sodium Salt is a biodegradable polymer used as an eco-friendly alternative to traditional scale inhibitors. It reduces environmental impact in agriculture, wastewater treatment, and detergent formulations while maintaining high efficiency.

Q: What distinguishes Sodium HEDP from Polyaspartic Acid Sodium Salt?

A: Sodium HEDP is a phosphonate-based inhibitor effective in harsh conditions, while Polyaspartic Acid Sodium Salt is a biodegradable, non-phosphorus polymer. Their chemical structures and environmental profiles differ significantly.

Q: Can Sodium of Polyaspartic Acid be used in cooling water systems?

A: Yes, Sodium of Polyaspartic Acid is effective in cooling water systems for scale inhibition and dispersing suspended particles. Its thermal stability and biodegradability make it suitable for sustainable water management.

Q: Why choose Sodium HEDP over other corrosion inhibitors?

A: Sodium HEDP offers superior chelation, stability in high temperatures, and compatibility with other additives. It is cost-effective for long-term use in industrial systems requiring robust corrosion control.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025