corrosion & scale inhibitors

Understanding Corrosion and Scale Inhibitors Importance and Applications

Corrosion and scale formation are significant challenges faced in various industries, including oil and gas, water treatment, and manufacturing. These issues can lead to equipment failure, increased maintenance costs, and operational inefficiencies. To mitigate these problems, the use of corrosion and scale inhibitors has become crucial. This article delves into the mechanisms of corrosion and scale formation, the types of inhibitors available, and their applications in different sectors.

The Nature of Corrosion

Corrosion is a natural process where metals deteriorate due to chemical or electrochemical reactions with their environment. Factors such as moisture, temperature, and the presence of corrosive agents can accelerate this process. Common types of corrosion include pitting, galvanic, and uniform corrosion. Pitting corrosion, for instance, typically occurs in stagnant water, while galvanic corrosion results from electrical contact between different metals. The consequences of corrosion are not only detrimental to the lifespan of equipment but also pose safety hazards.

Scale Formation

Scale formation, primarily seen in water systems, occurs when dissolved minerals precipitate out of the water, leading to the buildup of mineral deposits. This often happens in boilers, heat exchangers, and pipelines where water is heated and concentrated. Common scale-forming minerals include calcium carbonate, silica, and magnesium compounds. Scale can severely impair heat transfer, leading to increased energy consumption and operational costs. Like corrosion, scale formation prompts maintenance issues that can interrupt production processes.

Importance of Inhibitors

To combat corrosion and scale formation, various inhibitors are used. These substances help to minimize metal loss and scale accumulation, thereby extending the life of industrial equipment and ensuring efficient operation.

Types of Corrosion Inhibitors

1. Anodic Inhibitors These materials function by forming a protective oxide layer on the metal surface, which reduces the rate of oxidation. Common examples include chromates, which are effective but have environmental concerns due to their toxicity.

2. Cathodic Inhibitors By decreasing the cathodic reaction rate, these inhibitors help reduce the overall corrosion rate. Compounds like zinc and barium are frequently used in this category.

corrosion & scale inhibitors

3. Mixed Inhibitors These inhibitors offer the benefits of both anodic and cathodic inhibitors and are often used in complex environments. They can provide comprehensive protection for various metals.

Types of Scale Inhibitors

1. Threshold Inhibitors These are used in low concentrations to prevent the nucleation of scale. They work by interfering with the crystallization process of scale-forming minerals.

2. Chelating Agents These compounds bind with metal ions, preventing them from precipitating out of solution. Common chelating agents include citric acid and polyacrylic acid.

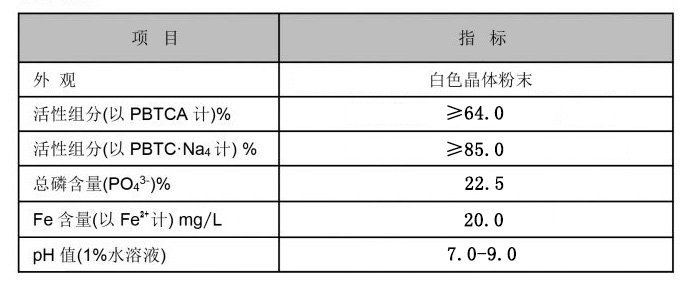

3. Organic Phosphonates These are particularly effective in high-temperature applications and can help control scale formation by changing the crystal growth patterns of scale-forming minerals.

Applications Across Industries

The application of corrosion and scale inhibitors is widespread across various sectors. In the oil and gas industry, these inhibitors are critical in maintaining pipeline integrity and ensuring safe transport of crude oil and natural gas. In water treatment facilities, they help manage the quality of water supplied to consumers by preventing scale buildup in treatment equipment.

Manufacturing processes that involve heat exchangers must also employ inhibitors to maintain efficiency and prevent downtime due to maintenance. Additionally, cooling systems benefit significantly from scale and corrosion inhibitors, which safeguard against costly repairs and replacements.

Conclusion

Corrosion and scale are persistent problems impacting various industries, but with the application of effective inhibitors, these challenges can be managed. By understanding the types of inhibitors available and their respective mechanisms, industries can take proactive steps to protect their assets, enhance operational efficiency, and reduce maintenance costs. As science and technology advance, the development of new and more effective corrosion and scale inhibitors will continue to play a vital role in industrial applications, contributing to sustainability and economic viability.

-

LK-319 Special Scale And Corrosion Inhibitor For Steel Plants: Advanced Solutions for Industrial Water SystemsNewsAug.22,2025

-

Flocculant Water Treatment: Essential Chemical Solutions for Purification ProcessesNewsAug.22,2025

-

Isothiazolinones: Versatile Microbial Control Agents for Industrial and Consumer ApplicationsNewsAug.22,2025

-

Scale Inhibitor: Key Solutions for Water System Scale PreventionNewsAug.22,2025

-

Organophosphonates: Versatile Scale Inhibitors for Industrial Water SystemsNewsAug.22,2025

-

Scale and Corrosion Inhibitor: Essential Chemical Solutions for Water System MaintenanceNewsAug.22,2025