Exploring the Applications and Benefits of Hydrolyzed Polyacrylamide in Various Industries and Processes

The Importance of Hydrolyzed Polyacrylamide in Modern Applications

Hydrolyzed polyacrylamide (HPAM) has gained significant attention in various industries due to its versatile properties and numerous applications. As a water-soluble polymer, HPAM is derived from polyacrylamide through a hydrolysis process that involves breaking down the polymer chains, which enhances its functionality. This article explores the characteristics, production, and applications of hydrolyzed polyacrylamide, shedding light on its growing significance in modern technology and environmental management.

Characteristics of Hydrolyzed Polyacrylamide

HPAM is characterized by its high molecular weight and excellent solubility in water. The hydrolysis process introduces functional groups, primarily carboxyl (-COOH) groups, which enhance the polymer's ability to interact with various substances, such as minerals and organic compounds. This alteration in the molecular structure leads to improved properties, including increased viscosity and enhanced flocculation capabilities, making HPAM an ideal choice for numerous applications.

One of the noteworthy features of hydrolyzed polyacrylamide is its ability to form gels with suspensions and colloids. This property is vital in applications that require the stabilization of soils and sediments, especially in the presence of water. Moreover, HPAM's biodegradability is a key aspect that distinguishes it from many synthetic polymers, positioning it as a more environmentally friendly alternative in industrial processes.

Production of Hydrolyzed Polyacrylamide

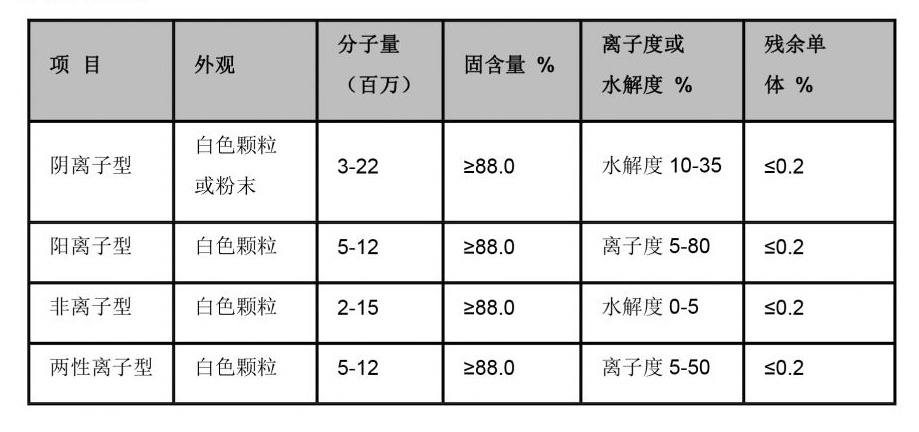

The production of HPAM involves the controlled hydrolysis of polyacrylamide, which can be achieved through various methods, including chemical hydrolysis and enzymatic hydrolysis. The degree of hydrolysis can be precisely controlled to tailor the polymer's properties for specific applications. This control allows manufacturers to produce HPAM with varying degrees of anionicity, which can influence its performance in different environments.

Applications of Hydrolyzed Polyacrylamide

hydrolyzed polyacrylamide

The applications of hydrolyzed polyacrylamide are vast and diverse, cutting across several industries

1. Oil and Gas Industry HPAM plays a crucial role in enhanced oil recovery (EOR) processes. It is used to improve the viscosity of water used in fracking operations, facilitating better oil extraction. By increasing water's ability to mobilize oil in porous rock formations, HPAM contributes to more efficient resource recovery.

2. Agriculture In agriculture, hydrolyzed polyacrylamide is employed as a soil conditioner. It helps in water retention, reducing soil erosion, and improving the overall soil structure. As a result, crops can grow more effectively, especially in arid regions, promoting sustainable farming practices.

3. Water Treatment HPAM is widely used in water treatment processes. Its flocculating properties aid in the separation of suspended solids from wastewater, thereby enhancing the clarity and quality of treated water. This capability is particularly important in municipal and industrial wastewater treatment facilities.

4. Cosmetics and Personal Care Products Due to its thickening and stabilizing properties, HPAM is also used in a variety of cosmetic and personal care products. It improves product texture and helps maintain the stability of emulsions, providing a desirable user experience.

5. Mining and Mineral Processing In the mining sector, HPAM is utilized as a flocculant to facilitate the separation of fine particulates from liquids in mineral processing.

Conclusion

In conclusion, hydrolyzed polyacrylamide stands out as a multifunctional polymer with wide-ranging applications across several industries. Its unique properties and versatility not only improve process efficiency but also promote environmentally sustainable practices. As research and technology continue to advance, the demand for hydrolyzed polyacrylamide is expected to grow, paving the way for innovative applications and enhanced effectiveness in current uses. The future of HPAM promises exciting opportunities for both industrial progress and ecological stewardship.

-

Understanding Polycarboxylic Acids: Properties, Applications, and Future PotentialNewsJul.28,2025

-

Scale Inhibitor Explained: How to Protect Your System from Limescale and Hard Water DamageNewsJul.28,2025

-

Scale and Corrosion Inhibitors: Essential Chemicals for Industrial Water System ProtectionNewsJul.28,2025

-

Polyaspartic Acid: A Biodegradable Polymer for Sustainable ChemistryNewsJul.28,2025

-

Isothiazolinones: A Versatile Antimicrobial Class with Industrial Power and Regulatory ChallengesNewsJul.28,2025

-

A Deep Dive into 2-Phosphonobutane-1,2,4-Tricarboxylic Acid (PBTC)NewsJul.28,2025