flocculant manufacturer

The Role of Flocculant Manufacturers in Water Treatment

Water is an essential resource for life, industries, and agriculture. However, the increasing levels of pollutants and contaminants in water bodies necessitate effective water treatment solutions. One of the most crucial components in water treatment processes is the use of flocculants. Flocculants are chemical substances that promote the clumping of particles in water, facilitating their removal. The role of flocculant manufacturers is critical in ensuring that industries and municipalities have access to the right products for effective water purification.

Understanding Flocculants

Flocculants work by neutralizing the charges on suspended particles, allowing them to agglomerate into larger flocs. These flocs can then be easily separated from the water through sedimentation or filtration. Flocculants are widely used in various applications, including drinking water treatment, wastewater treatment, and even in certain industrial processes. The effectiveness of flocculants can vary greatly depending on their chemical composition, with common types including polyacrylamides, natural starches, and chitosan-based products.

The Role of Flocculant Manufacturers

Flocculant manufacturers play a pivotal role in producing and supplying these vital chemicals. Their responsibilities extend from research and development to distribution and customer support. Here are some key functions that these manufacturers perform

1. Research and Development Flocculant manufacturers invest heavily in research to develop new and more efficient flocculant formulations. This is especially important as environmental regulations become stricter, and the demand for cleaner water increases. Innovative products can help wastewater treatment facilities operate more efficiently and reduce the environmental impact of their operations.

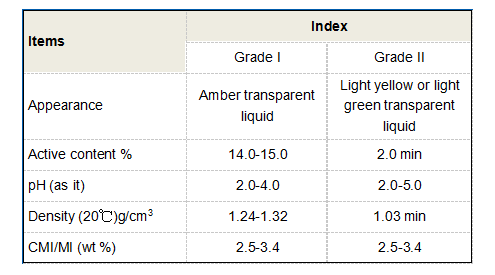

2. Quality Control The quality of flocculants can significantly affect the water treatment process. Manufacturers follow stringent quality control measures to ensure that their products meet established standards and specifications. This includes testing for efficacy, safety, and environmental impact, ensuring that customers receive a consistent and reliable product.

flocculant manufacturer

3. Customization and Technical Support Industries often have unique requirements based on the specific contaminants present in their water sources. Flocculant manufacturers work closely with clients to understand their needs and may provide customized solutions tailored to specific conditions. Additionally, technical support is offered to help customers optimize their flocculation processes and improve overall water treatment efficiency.

4. Sustainability Practices As the focus on environmental sustainability increases, many flocculant manufacturers are seeking to reduce their ecological footprint. This can involve sourcing raw materials from sustainable suppliers, reducing waste during production, and designing biodegradable flocculant products. Sustainable practices not only benefit the environment but can also enhance a manufacturer's reputation and appeal to eco-conscious clients.

5. Education and Training Flocculant manufacturers often offer training programs and educational resources for their clients. This can include workshops on the proper application of flocculants, troubleshooting common issues, and understanding the chemistry behind flocculation. Educating clients helps ensure that they are making the most of the products and achieving optimal results in their water treatment efforts.

Market Trends and Challenges

The flocculant manufacturing industry is impacted by several market trends and challenges. The push for zero liquid discharge in industrial processes is driving demand for innovative flocculants that can enhance recovery rates. Additionally, the rise of smart water management technologies is changing how companies approach water treatment, creating further opportunities for flocculant manufacturers to adapt and innovate.

However, manufacturers also face challenges, including fluctuating raw material costs and regulatory changes. Adapting to these challenges requires flexibility and a commitment to continuous improvement.

Conclusion

Flocculant manufacturers are essential players in the water treatment sector, providing the necessary chemical solutions to ensure clean and safe water for various applications. Their role encompasses research and development, quality control, customization, and sustainability initiatives. As environmental concerns grow and water treatment needs evolve, these manufacturers will continue to innovate, ensuring that industries and municipalities are equipped with effective and efficient water treatment solutions. The future of clean water relies heavily on the advancements made by flocculant manufacturers today.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025