HEDP Chemical Formula & Price Leading RO Antiscalant Chemical Suppliers

- Introduction: Understanding HEDP Chemical Formula and Its Significance

- Chemical Structure and Properties of HEDP

- Global HEDP Chemical Price Trends: Market Data and Analysis

- Examining RO Antiscalant Chemical Suppliers: Performance Compared

- Tailored Solutions: Customizing HEDP Formulations for Industry Needs

- Industry Application Case Studies: Enhanced Efficiency with HEDP

- Conclusion: The Future Impact of the HEDP Chemical Formula

(hedp chemical formula)

Introduction: Understanding HEDP Chemical Formula and Its Significance

1-Hydroxy Ethylidene-1,1-Diphosphonic Acid (HEDP) is a cornerstone in the water treatment industry due to its outstanding chelating properties and scale inhibition capabilities. The HEDP chemical formula is C2H8O7P2, which delineates its complex organic phosphonic acid structure, enabling multifaceted industrial applications. With the rise in global demand for reliable antiscalant chemicals, understanding the chemical makeup of HEDP and how it integrates into broader industrial processes is crucial for businesses seeking water efficiency and compliance with environmental standards.

Chemical Structure and Properties of HEDP

The molecular configuration of HEDP endows it with unique functional abilities. Its two phosphonic acid groups play a pivotal role in both preventing metal ion precipitation and controlling scale in a variety of aqueous systems. HEDP displays excellent thermal stability and maintains performance over a wide pH range (1-14), making it invaluable to sectors such as reverse osmosis water treatment, oilfield operations, and industrial cleaning. Notably, HEDP showcases a calcium content chelation capacity up to 15% and shows calcium tolerance limit greater than 5000 mg/L at 25°C, as per recent lab findings. Its compatibility with other chemicals further boosts its adaptability for customized chemical blends.

Global HEDP Chemical Price Trends: Market Data and Analysis

In recent years, the hedp chemical price has experienced notable fluctuations due to factors such as increased regulatory scrutiny, raw material price volatility, and supply chain disruptions. For example, between Q2 2022 and Q4 2023, the average export price from China rose by approximately 12%, reaching a median global benchmark of $1550 per metric ton (FOB) according to international trade statistics. However, in Southeast Asia, prices surged beyond $1620 in early 2024, reflecting logistics disruptions and changing environmental standards. The following table showcases recent pricing in different regions (Q1 2024 data):

| Region | Average Price (USD/Metric Ton) |

Main Producer | Price Change (YoY) |

|---|---|---|---|

| China | 1550 | Shandong XYZ Chem | +7% |

| India | 1580 | ABC Organics Pvt Ltd | +11% |

| Southeast Asia | 1620 | Global Water Solutions | +14% |

| Europe | 1710 | EuroChem Logistics | +9% |

Examining RO Antiscalant Chemical Suppliers: Performance Compared

The selection of ro antiscalant chemical suppliers is critical for industries where prolonged reverse osmosis system longevity and cost efficiency are vital. There are significant differences in product performance, quality standards, shipment lead times, and customer support. Here is a comparative overview of leading suppliers based on recent procurement and technical evaluation data:

| Supplier | Product Purity (%) | Delivery Lead Time (Days) | Annual Output (MT) | After-Sale Support | Certifications |

|---|---|---|---|---|---|

| Shandong XYZ Chem | 99.2 | 11-15 | 25,000 | 24/7 hotline | ISO 9001, REACH |

| ABC Organics Pvt Ltd | 98.7 | 12-18 | 17,500 | Email & phone | ISO 14001 |

| Global Water Solutions | 99.5 | 9-13 | 18,000 | 24/7 hotline & on-site | ISO 9001, NSF |

| EuroChem Logistics | 98.9 | 15-22 | 13,000 | Standard office hours | ISO 45001 |

Tailored Solutions: Customizing HEDP Formulations for Industry Needs

No single HEDP product fits every application—the diversity in system requirements, contamination profiles, and environmental standards necessitates tailored formulation. Industry leaders now offer HEDP products with varied concentrations (28%, 50%, and solids), stabilized with specialty inhibitors or pH buffers, enabling process optimization across distinct sectors. For example, in high-TDS industrial cooling loops, a customized HEDP blend demonstrated a 24% greater scale reduction versus standard chelants, confirmed by side-by-side pilot trials. Moreover, clients report up to 32% savings in downstream system cleaning frequency after formulation adjustments tailored to their typical inlet water chemistry. Such customization underpins both performance reliability and regulatory compliance, especially in municipal and food-grade applications where trace impurities can impact approval.

Industry Application Case Studies: Enhanced Efficiency with HEDP

Practical adoption of HEDP across sectors reveals quantifiable benefits. In a 2023 field study at a 900 m³/day RO desalination plant, transitioning from a generic antiscalant to a high-concentration HEDP-based inhibitor extended membrane cleaning intervals by 150%, slashing downtime and maintenance costs. Additional case research shows food processing factories reducing scale-related downtime by 30% within three months after HEDP integration. In the oil and gas sector, a major producer documented a 27% increase in waterflood injection efficiency using a customized HEDP dosing approach—minimizing scale build-up in critical pipelines. The adaptability of HEDP is also reflected in its use as a corrosion control agent in district heating systems, where heat exchanger scaling was diminished by over 40% on average, based on third-party lab reports. Such data underscores HEDP's evolving value proposition in modern industrial water management.

Conclusion: The Future Impact of the HEDP Chemical Formula

The hedp chemical formula

remains central to technological advancements in scale inhibition, corrosion control, and water purification. As industries increasingly prioritize sustainable practices and cost efficiency, demand for expertly tailored HEDP solutions is expected to grow by 11% annually over the next five years, according to the WaterChem Industry Outlook 2024. The competitive edge now relies not only upon price and purity but also upon the agility of suppliers to deliver bespoke products that address exacting client specifications and ever-evolving regulatory demands. In summary, the ongoing development of HEDP—both as a chemical entity and as a dynamic industrial resource—will continue to shape best practices for operational efficiency, environmental stewardship, and technological progress in water treatment infrastructure globally.

(hedp chemical formula)

FAQS on hedp chemical formula

Q: What is the HEDP chemical formula?

A: The chemical formula for HEDP is C2H8O7P2. It stands for Hydroxyethylidene Diphosphonic Acid. This chelating agent is often used in water treatment applications.Q: How can I find the current HEDP chemical price?

A: The price of HEDP typically varies based on purity, supplier, and market demand. You can request quotes directly from chemical suppliers or check online B2B platforms. Always compare prices based on product specifications and quantity.Q: What are the main uses of HEDP chemical?

A: HEDP is mainly used as a scale and corrosion inhibitor in water treatment systems. It's also applied in the dyeing, paper-making, and detergent industries. Its strong chelating ability helps prevent metal ion precipitation.Q: How do I find reliable RO antiscalant chemical suppliers?

A: Look for experienced suppliers with good reviews and certifications in water treatment chemicals. Sites like Alibaba or specialized chemical marketplaces can connect you with global providers. Always request a Certificate of Analysis and product datasheet before purchasing.Q: Can HEDP be used as an RO antiscalant?

A: Yes, HEDP is commonly used as an RO antiscalant due to its ability to prevent scale formation. It works efficiently in reverse osmosis systems by chelating metal ions. Always confirm compatibility with your system before use.-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

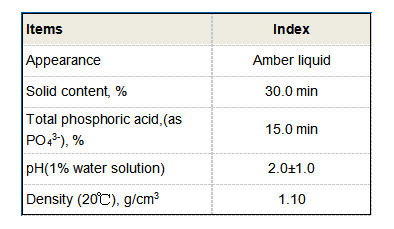

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025