industrial flocculant

Understanding Industrial Flocculants Applications and Benefits

In the realm of industrial processes, particularly in waste treatment, water purification, and mineral processing, flocculants play a crucial role. These chemical agents facilitate the agglomeration of suspended particles in a liquid, making them easy to remove. The importance of understanding industrial flocculants cannot be overstated, as they contribute significantly to operational efficiency, environmental protection, and the overall sustainability of industrial practices.

What Are Flocculants?

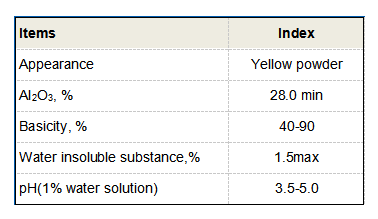

Flocculants are substances that promote the clumping of particles in a liquid solution. Their primary function is to aggregate fine solid particles into larger masses or flocs, which can then be easily separated from the slurry through sedimentation, filtration, or flotation. Depending on their chemical composition, flocculants can be categorized into different types, including synthetic polymers, natural organic flocculants like starch and cellulose derivatives, and inorganic compounds such as alum and ferric chloride.

The Mechanism of Action

The effectiveness of flocculants is rooted in their ability to enhance the interaction between particles suspended in a liquid. When flocculants are introduced into a suspension, they neutralize the charge on the particles, which often repels one another. This neutralization allows particles to come closer together, leading to the formation of larger aggregates. The larger the floc, the easier it is for it to settle or be removed from the liquid. This process is vital in a variety of industrial applications where clarity of water or the recovery of valuable material is necessary.

Applications of Industrial Flocculants

1. Water Treatment One of the most common uses of flocculants is in water treatment facilities. They are used to clarify drinking water, remove turbidity, and help in the separation of sludge from treated water. By enhancing the sedimentation of particles, flocculants ensure that water meets health and safety standards.

2. Wastewater Treatment In wastewater treatment plants, flocculants play a key role in the removal of suspended solids, phosphorus, nitrogen, and other contaminants. The use of flocculants in this context not only aids in the cleaning process but also helps in recovering valuable by-products.

industrial flocculant

3. Mineral Processing Flocculants are widely used in the mining industry to beneficiate ore and recover valuable minerals from slurries. They allow for effective separation of fines from larger particles, optimizing resource recovery while minimizing waste.

4. Pulp and Paper Industry In the pulp and paper sector, flocculants are used to clarify process water and remove lignin and other residues from pulp. They enhance the quality of the final product while reducing water consumption and energy demands.

5. Food Industry Flocculants find use in the food industry for clarification processes, such as in the production of fruit juices and beverages, where the removal of fine particles is essential for achieving a clear product.

Benefits of Using Flocculants

The incorporation of flocculants in industrial applications offers several benefits. Firstly, they improve the efficiency of separation processes, reducing the time and resources needed for sedimentation and clarification. This enhanced efficiency translates to cost savings and increased productivity.

Secondly, the use of flocculants aids in the environmental management of industrial waste. By effectively removing contaminants and recovering useful materials, businesses can minimize their ecological footprint and comply with regulations.

Lastly, advancements in flocculant technology have led to the development of more eco-friendly options. Biodegradable and less toxic flocculants are now available, allowing industries to adopt sustainable practices while maintaining operational effectiveness.

Conclusion

In conclusion, industrial flocculants play an integral role in various sectors, aiding in the effective management of liquids and improving overall industrial efficiency. As industries continue to face challenges related to sustainability and environmental impact, the importance of flocculants will likely increase. By leveraging these chemical agents, industries can enhance their operations, reduce waste, and contribute to a cleaner, more sustainable future. As research and technology progress, the potential applications and benefits of flocculants will undoubtedly expand, reinforcing their significance in the industrial landscape.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025