Jul . 06, 2024 03:30

Back to list

Managing scale and corrosion in cooling towers with effective inhibitors to improve performance.

Scale and Corrosion Inhibitor for Cooling Tower

Cooling towers play a crucial role in industrial processes by removing heat from various sources such as machinery or heated process material. However, over time, these cooling towers can be plagued by two common issues scale buildup and corrosion. Scale is caused by the accumulation of minerals in the water, while corrosion occurs when metal surfaces are attacked by the water or chemicals present in the system. To combat these problems, a scale and corrosion inhibitor is often added to the cooling tower water.

Scale inhibitors work by either preventing mineral ions from precipitating and forming scale or by dispersing these ions so they do not accumulate. They can be organic or inorganic chemicals that interact with the minerals in the water to keep them in solution. By preventing scale buildup, these inhibitors not only help maintain the efficiency of the cooling tower but also extend its lifespan.

On the other hand, corrosion inhibitors form a protective film on metal surfaces to prevent the water from coming into direct contact with the metal. This film acts as a barrier, reducing the chances of corrosion occurring. Corrosion inhibitors can be organic or inorganic compounds that interact with the metal surface to form a protective layer. By inhibiting corrosion, these chemicals help prevent the degradation of the cooling tower components and maintain the integrity of the system.

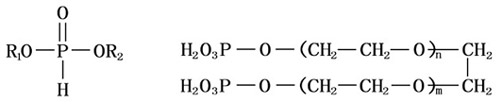

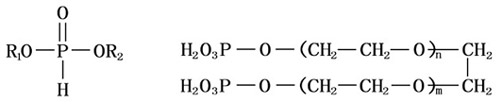

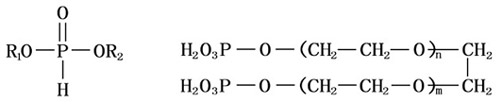

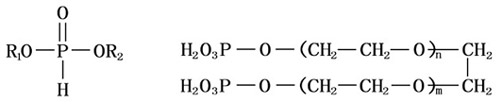

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds scale and corrosion inhibitor for cooling tower. These compounds are effective in preventing scale formation and inhibiting corrosion in a wide range of water conditions. Phosphonates work by forming complexes with metal ions and preventing them from interacting with other substances in the water. This helps in keeping the minerals in solution and protecting the metal surfaces from corrosion.

Another popular inhibitor is polyacrylic acid, which is effective in dispersing mineral ions and preventing the formation of scale. Polyacrylic acid molecules adsorb onto the mineral surfaces, preventing them from aggregating and forming scale deposits. This inhibitor is also effective in inhibiting corrosion by forming a protective film on metal surfaces.

In conclusion, scale and corrosion inhibitors are essential additives for maintaining the efficiency and longevity of cooling towers. By preventing scale buildup and inhibiting corrosion, these chemicals help ensure the smooth operation of the cooling tower and reduce the need for costly repairs and replacements. Choosing the right inhibitor based on water quality and system requirements is crucial in ensuring the optimal performance of the cooling tower. With the right inhibitor in place, industrial processes can run smoothly and efficiently without the threat of scale and corrosion issues.

scale and corrosion inhibitor for cooling tower. These compounds are effective in preventing scale formation and inhibiting corrosion in a wide range of water conditions. Phosphonates work by forming complexes with metal ions and preventing them from interacting with other substances in the water. This helps in keeping the minerals in solution and protecting the metal surfaces from corrosion.

Another popular inhibitor is polyacrylic acid, which is effective in dispersing mineral ions and preventing the formation of scale. Polyacrylic acid molecules adsorb onto the mineral surfaces, preventing them from aggregating and forming scale deposits. This inhibitor is also effective in inhibiting corrosion by forming a protective film on metal surfaces.

In conclusion, scale and corrosion inhibitors are essential additives for maintaining the efficiency and longevity of cooling towers. By preventing scale buildup and inhibiting corrosion, these chemicals help ensure the smooth operation of the cooling tower and reduce the need for costly repairs and replacements. Choosing the right inhibitor based on water quality and system requirements is crucial in ensuring the optimal performance of the cooling tower. With the right inhibitor in place, industrial processes can run smoothly and efficiently without the threat of scale and corrosion issues.

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds

One commonly used scale and corrosion inhibitor for cooling towers is phosphonate-based compounds scale and corrosion inhibitor for cooling tower. These compounds are effective in preventing scale formation and inhibiting corrosion in a wide range of water conditions. Phosphonates work by forming complexes with metal ions and preventing them from interacting with other substances in the water. This helps in keeping the minerals in solution and protecting the metal surfaces from corrosion.

Another popular inhibitor is polyacrylic acid, which is effective in dispersing mineral ions and preventing the formation of scale. Polyacrylic acid molecules adsorb onto the mineral surfaces, preventing them from aggregating and forming scale deposits. This inhibitor is also effective in inhibiting corrosion by forming a protective film on metal surfaces.

In conclusion, scale and corrosion inhibitors are essential additives for maintaining the efficiency and longevity of cooling towers. By preventing scale buildup and inhibiting corrosion, these chemicals help ensure the smooth operation of the cooling tower and reduce the need for costly repairs and replacements. Choosing the right inhibitor based on water quality and system requirements is crucial in ensuring the optimal performance of the cooling tower. With the right inhibitor in place, industrial processes can run smoothly and efficiently without the threat of scale and corrosion issues.

scale and corrosion inhibitor for cooling tower. These compounds are effective in preventing scale formation and inhibiting corrosion in a wide range of water conditions. Phosphonates work by forming complexes with metal ions and preventing them from interacting with other substances in the water. This helps in keeping the minerals in solution and protecting the metal surfaces from corrosion.

Another popular inhibitor is polyacrylic acid, which is effective in dispersing mineral ions and preventing the formation of scale. Polyacrylic acid molecules adsorb onto the mineral surfaces, preventing them from aggregating and forming scale deposits. This inhibitor is also effective in inhibiting corrosion by forming a protective film on metal surfaces.

In conclusion, scale and corrosion inhibitors are essential additives for maintaining the efficiency and longevity of cooling towers. By preventing scale buildup and inhibiting corrosion, these chemicals help ensure the smooth operation of the cooling tower and reduce the need for costly repairs and replacements. Choosing the right inhibitor based on water quality and system requirements is crucial in ensuring the optimal performance of the cooling tower. With the right inhibitor in place, industrial processes can run smoothly and efficiently without the threat of scale and corrosion issues. Share

Latest news

-

Understanding Polycarboxylic Acids: Properties, Applications, and Future PotentialNewsJul.28,2025

-

Scale Inhibitor Explained: How to Protect Your System from Limescale and Hard Water DamageNewsJul.28,2025

-

Scale and Corrosion Inhibitors: Essential Chemicals for Industrial Water System ProtectionNewsJul.28,2025

-

Polyaspartic Acid: A Biodegradable Polymer for Sustainable ChemistryNewsJul.28,2025

-

Isothiazolinones: A Versatile Antimicrobial Class with Industrial Power and Regulatory ChallengesNewsJul.28,2025

-

A Deep Dive into 2-Phosphonobutane-1,2,4-Tricarboxylic Acid (PBTC)NewsJul.28,2025