pbtc scale inhibitorpbtc

The Importance of PBTC Scale Inhibitors in Industrial Applications

In various industrial processes, scale formation can lead to significant operational challenges and increased maintenance costs. One of the most effective solutions to prevent scale build-up is the use of scale inhibitors, specifically Phosphonobutane-1,2,4-Tricarboxylic Acid, or PBTC. This article explores the nature of PBTC as a scale inhibitor, its effectiveness, and its applications in diverse industries.

Understanding Scale Formation

Scale formation typically occurs in systems that handle water, such as cooling towers, boilers, and heat exchangers. Minerals dissolved in water, particularly calcium carbonate, calcium sulfate, barium sulfate, and magnesium silicate, can precipitate and form solid deposits when conditions change, such as during evaporation or temperature fluctuations. These deposits can cause blockages, increase energy consumption, decrease heat transfer efficiency, and ultimately lead to equipment damage.

What is PBTC?

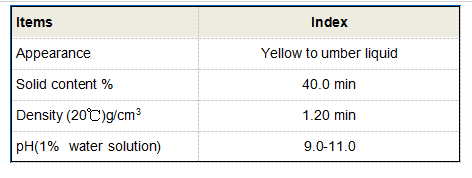

PBTC is a highly effective organic scale inhibitor with a multi-functional structure that enhances its performance in controlling scale formation. It is a part of the phosphonic acid family, which provides it with strong metal-binding capabilities. This unique characteristic allows PBTC to effectively disrupt the crystallization process of scale-forming minerals, thus preventing their aggregation and adhesion to surfaces.

Effectiveness of PBTC

The effectiveness of PBTC as a scale inhibitor relies on several mechanisms. Firstly, PBTC has a high affinity for calcium ions, which are key players in scale formation. By binding to these ions, PBTC prevents them from participating in scale formation reactions. Secondly, PBTC is also effective in dispersing existing scale, which further aids in maintaining clean system surfaces. Additionally, PBTC’s stability under varying pH and temperature conditions makes it a versatile choice for different applications.

Numerous studies have demonstrated PBTC's superior performance compared to traditional scale inhibitors, such as phosphates and polyacrylates. For instance, in high-temperature environments, PBTC not only outperforms other inhibitors in preventing scale but also maintains lower concentrations, making it an economically viable option.

Applications of PBTC

pbtc scale inhibitorpbtc

PBTC is widely used across various industries, including

1. Power Generation In cooling towers and boiler systems, PBTC helps in minimizing scale formation, which can lead to operational inefficiencies and increased maintenance costs due to the deposition of calcium and other minerals.

2. Oil and Gas In the extraction and processing of hydrocarbons, PBTC is utilized to prevent scale deposits in pipelines and processing equipment, ensuring smooth operations and extending equipment life.

3. Textile Industry In textile processing, where water quality significantly affects dyeing and finishing, PBTC is used to control scale that can interfere with fabric treatments.

4. Water Treatment PBTC is also employed in municipal and industrial water treatment facilities to prevent the formation of scale in reverse osmosis membranes and other filtration systems.

Environmental Considerations

An essential aspect of PBTC is its environmentally friendly profile compared to some traditional scale inhibitors. Being biodegradable and having low toxicity levels, PBTC presents a more sustainable alternative for industries looking to minimize their environmental impact while maintaining operational efficiency.

Conclusion

The use of PBTC as a scale inhibitor addresses one of the critical challenges faced by various industries. Its effectiveness in preventing scale formation, combined with its environmentally friendly properties, makes it a preferable choice over more traditional options. Industries can achieve greater operational efficiency, reduced maintenance costs, and prolonged equipment life by incorporating PBTC into their water management strategies. As technology advances, the application of PBTC and similar compounds will likely expand, contributing further to sustainable industrial practices.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025