Applications and Benefits of Polyaluminum Chloride in Water Treatment Processes

Understanding Polyaluminum Chloride Coagulant A Key Player in Water Treatment

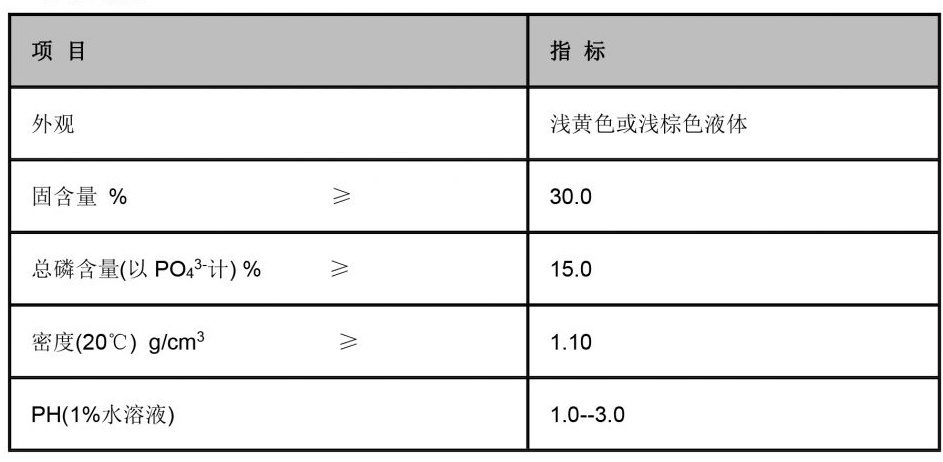

Polyaluminum chloride (PAC) is a versatile coagulant widely used in water treatment processes. Its chemical composition typically includes multiple aluminum ions and chloride ions, which impart its unique properties that make it highly effective for various applications, including drinking water purification, wastewater treatment, and industrial applications.

The Chemistry of Polyaluminum Chloride

Polyaluminum chloride is a polymeric form of aluminum chloride and is available in various formulations, depending on the intended use. It is produced by reacting aluminum hydroxide with hydrochloric acid, resulting in a product that contains a mixture of different polymeric species. The primary benefit of PAC over traditional coagulants, like aluminum sulfate, lies in its ability to form larger flocs—clumps of particles—more efficiently at a lower dosage. This results in improved sedimentation and filtration, which are critical processes in water treatment.

Mechanism of Action

PAC operates through a mechanism known as charge neutralization and bridging. When PAC is added to water, it dissociates and releases aluminum ions. These aluminum ions neutralize the negative charge of colloidal particles suspended in the water, such as silt, organic matter, and microorganisms. Once neutralized, these particles can begin to clump together, forming larger aggregates or flocs. As these flocs grow in size, they can settle more easily to the bottom of the treatment tank or be removed through filtration.

This process not only enhances the removal of turbidity (the cloudiness caused by suspended particles) but also effectively reduces the presence of harmful pathogens and organic pollutants, making PAC an essential coagulant for safe drinking water production.

Advantages of Using PAC

The use of polyaluminum chloride offers several advantages over traditional coagulants

2. Broader pH Range PAC performs well across a wider pH range compared to other coagulants. This versatility allows for its use in diverse water chemistry conditions, making it suitable for various applications.

polyaluminum chloride coagulant

3. Fast Settling The formation of larger flocs facilitates rapid settling and clarification, resulting in shorter processing times. This efficiency improves overall plant productivity.

4. Reduced Sludge Production PAC generates less sludge compared to aluminum sulfate, which simplifies sludge handling and disposal in treatment facilities.

5. Improved Water Quality PAC not only enhances turbidity removal but also reduces levels of dissolved organic carbon (DOC), trihalomethanes (THMs), and other disinfection by-products, ensuring higher quality water.

Applications of PAC

Polyaluminum chloride is extensively used in different sectors. In municipal water treatment facilities, it plays a crucial role in ensuring that drinking water meets safety and quality standards. It is also used in wastewater treatment plants to treat industrial effluents, where it efficiently removes heavy metals and organic pollutants.

In the food industry, PAC finds applications in clarifying juices and beverages. Furthermore, in the paper industry, it is used as a retention aid, helping to improve product quality and reduce wastewater treatment costs.

Environmental Considerations

Although PAC is highly effective, environmental considerations must be taken into account. Excessive use of aluminum can lead to potential toxicity in aquatic environments. Therefore, it is essential for water treatment facilities to optimize dosing protocols and monitor aluminum levels to minimize environmental impact.

Conclusion

Polyaluminum chloride has emerged as a preferred choice for coagulants in water treatment due to its high efficiency and versatility. Its ability to enhance water quality in various applications makes it invaluable for meeting public health goals and environmental regulations. As the demand for safe and clean water continues to grow, PAC will likely play an increasingly prominent role in the future of water treatment technology. As with all chemicals, its use must be balanced with environmental stewardship to ensure sustainable practices in water management.

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025