Trends and Factors Influencing Poly Aluminum Chloride Pricing in the Market

Understanding Poly Aluminum Chloride Prices Factors and Trends

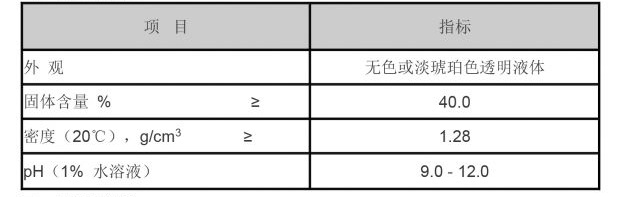

Poly Aluminum Chloride (PAC) is a widely used coagulant in various industries, particularly in water treatment, paper manufacturing, and food processing. Its effectiveness in removing impurities, including colloidal particles and turbidity from water, has made it a key player in the purification processes. However, end-users often find themselves concerned about PAC pricing trends and factors influencing its cost. This article delves into the elements that affect the price of poly aluminum chloride and some current trends.

Factors Influencing Poly Aluminum Chloride Prices

1. Raw Material Costs The production of PAC involves the use of aluminum raw materials, hydrochloric acid, and other chemical components. Fluctuations in the prices of these raw materials can significantly impact the cost of PAC. For instance, an increase in aluminum prices due to market demand or mining restrictions can lead to higher PAC prices. Conversely, a drop in aluminum prices may provide some respite to manufacturers and consumers.

2. Production Process The manufacturing process of PAC can also affect its price. Various production methods exist, each with different cost implications. For example, PAC can be produced through neutralizing aluminum hydroxide with hydrochloric acid, but this process may vary in efficiency and cost depending on the technology and infrastructure used in the manufacturing facility. Innovations that enhance production efficiency or reduce waste may help in stabilizing prices.

3. Market Demand The demand for PAC is significantly influenced by the industries that utilize it. For instance, an increase in demand for drinking water treatment due to population growth or heightened environmental regulations can drive up prices. Similarly, seasonal demand fluctuations, such as increased use in agriculture during certain planting seasons, can also affect pricing patterns.

4. Regulatory Influences Compliance with environmental and safety regulations can impact PAC prices. Stricter regulations may necessitate higher production costs due to the need for upgraded equipment or enhanced safety measures. Additionally, regulations can affect the demand for PAC if alternatives are more eco-friendly or economically viable. Manufacturers must stay abreast of these changes, as they can lead to either increased costs or opportunities in the market.

poly aluminum chloride price

5. Geopolitical Factors Political instability, trade policies, and economic sanctions can influence the availability and pricing of raw materials, particularly in countries rich in aluminum resources. Geopolitical tensions can lead to supply chain disruptions, creating shortages that drive prices higher. Import tariffs can also add to costs for consumers dependent on international sources for PAC.

Current Trends in Poly Aluminum Chloride Pricing

As of late 2023, the PAC market has experienced notable changes. Global supply chains have been recovering from the disruptions caused by the COVID-19 pandemic, leading to some stabilization in pricing. However, the ongoing conflict in various regions and fluctuating energy prices continue to exert pressure on the market. Prices may rise if energy costs increase, as energy-intensive processes are central to PAC production.

Moreover, the push for sustainability has led to innovations in PAC production. Some manufacturers are exploring eco-friendlier alternatives and production methods, which may influence prices in the long run. The growing emphasis on reducing carbon footprints may lead to higher costs initially, but it could also stabilize prices by opening new markets for sustainably produced PAC.

In addition, the expansion of wastewater treatment facilities and investment in municipal water systems are likely to stimulate demand for PAC. As countries enhance their infrastructure to improve water quality, the need for effective coagulants will grow, potentially leading to price increases as manufacturers respond to higher demand.

Conclusion

The pricing of poly aluminum chloride remains a dynamic aspect influenced by various factors ranging from raw material costs and production processes to market demand and geopolitical scenarios. Understanding these elements is crucial for industries reliant on PAC, as they navigate pricing fluctuations and seek strategic sourcing solutions. As we move forward, it will be essential for stakeholders to keep an eye on market trends and regulatory developments that could impact PAC pricing and availability. Staying informed will enable manufacturers and end-users alike to make educated decisions in this evolving landscape.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025