polydisperse hedp

Understanding Polydisperse HEDP A Comprehensive Overview

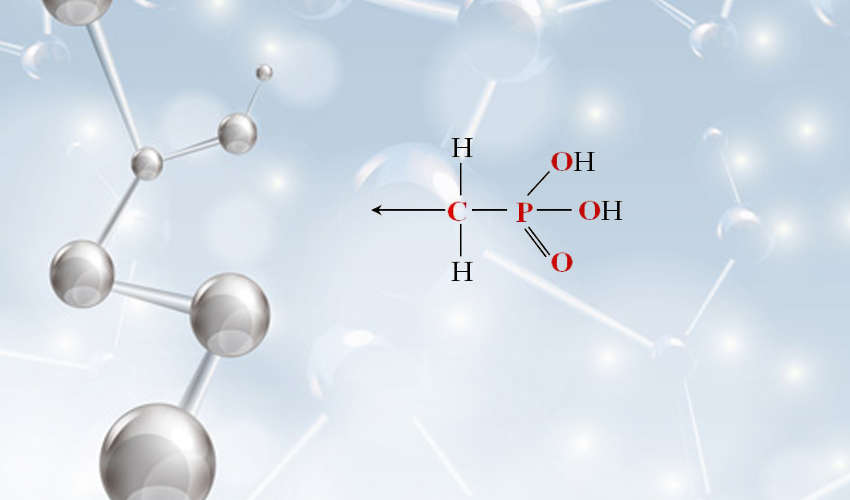

HEDP, or Hydroxyethylidene Diphosphonic Acid, is a well-known phosphonic acid derivative that has gained significant attention in various industrial applications, particularly in water treatment and corrosion inhibition. When discussing HEDP, the term polydisperse often arises, referring to a mixture where the molecular weight distribution varies widely. This article aims to explore the concept of polydisperse HEDP, its implications, and its applications in different fields.

What is Polydisperse HEDP?

Polydisperse HEDP signifies that the HEDP molecules present in a sample do not all have the same molecular weight. In contrast to monodisperse systems, where all molecules are similar, polydisperse systems contain a range of molecular sizes. This polydispersity can stem from the synthetic processes used to produce HEDP or from subsequent degradation phenomena during its use.

Importance of Polydispersity

Polydispersity plays a crucial role in determining the physical and chemical properties of HEDP. The variation in molecular weights can influence

1. Solubility Polydisperse HEDP may exhibit different solubility characteristics compared to its monodisperse counterparts. This variation affects its efficacy in different water chemistries and temperatures.

2. Reaction Kinetics The distribution of molecular weights can alter how HEDP interacts with metal ions and other components in water systems. Polydisperse systems may promote more complex reactions compared to uniform systems.

polydisperse hedp

3. Performance Efficiency In applications such as scale prevention and corrosion inhibition, the polydisperse nature of HEDP can enhance its performance by allowing it to interact with a broader range of surfaces and metal ions.

Applications of Polydisperse HEDP

1. Water Treatment Polydisperse HEDP is widely used in water treatment systems, particularly in cooling water circuits. It acts as a scale inhibitor, preventing the formation of calcium phosphate and other mineral scales that can diminish system efficiency. The presence of various molecular weights allows for greater adaptability in different water qualities and flow conditions.

2. Corrosion Inhibition In industrial settings, polydisperse HEDP is utilized to protect pipelines, boilers, and heat exchangers from corrosion. The diverse structure of the HEDP molecules contributes to a more robust protective layer on metal surfaces, reducing the likelihood of corrosion. The ability of polydisperse HEDP to function effectively across varying pH levels and temperatures makes it particularly valuable in maintaining operational integrity.

3. Adhesives and Coatings In the refinement of adhesives and coatings, polydisperse HEDP shows promise due to its ability to enhance bonding properties and durability. Its presence can improve the adhesion of coatings to substrates, contributing to long-lasting protective layers.

4. Agricultural Applications There is a growing interest in utilizing polydisperse HEDP in agriculture, particularly in controlling scale formation in irrigation systems. By preventing mineral build-up, HEDP enhances water flow and ensures that nutrients are delivered effectively.

Conclusion

Polydisperse HEDP represents a significant advancement in chemical formulations for various industrial applications. Understanding its polydisperse nature is crucial for optimizing its use in water treatment, corrosion inhibition, and beyond. As industries continue to seek sustainable and efficient solutions to manage resources, the versatility and effectiveness of polydisperse HEDP will undoubtedly play a pivotal role in future innovations. Through ongoing research and development, we can expect to see even broader applications and improved formulations that leverage the unique properties of polydisperse HEDP.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025