Scale-Free Efficiency: How Inhibitors Keep Your Equipment Running Smoothly

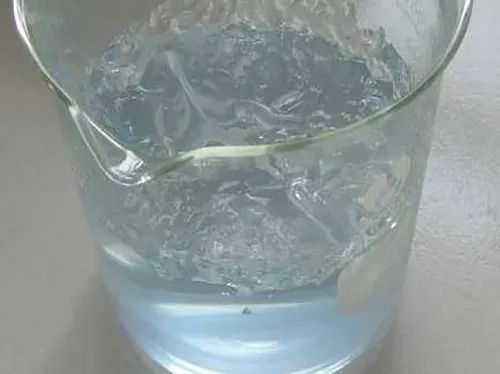

In industries where water systems are integral to operations, scale and corrosion can cause significant problems, reducing efficiency and leading to costly repairs. Fortunately, scale and corrosion inhibitors for cooling towers and other industrial systems offer a powerful solution. These inhibitors work by preventing the formation of harmful mineral deposits and protecting the equipment from corrosion, ensuring that operations run smoothly.

LK-1100 Modified Polyacrylic Acid: A Powerful Scale Inhibitor

LK-1100 Modified Polyacrylic Acid is a highly effective scale and corrosion inhibitor for cooling towers. This modified version of polyacrylic acid offers superior performance in preventing mineral scale buildup, particularly in high-heat environments. Cooling towers are especially vulnerable to scaling due to the constant flow of water and exposure to heat, making it essential to have an effective inhibitor to prevent damage.

The unique formulation of LK-1100 Modified Polyacrylic Acid prevents calcium and magnesium ions from crystallizing and adhering to surfaces, which is a common cause of scale formation. By keeping these minerals suspended in the water, this inhibitor ensures that your equipment remains free from scaling, maintaining efficient heat exchange and reducing maintenance costs. It also helps to prevent corrosion, which is a critical factor in prolonging the life of cooling towers and other water systems.

Acrylic Acid Homopolymer: Versatile Protection for Industrial Systems

The use of acrylic acid homopolymer in scale and corrosion inhibitors for cooling towers is becoming increasingly popular due to its versatility and effectiveness. This polymer works by forming a protective layer on metal surfaces, preventing the adhesion of minerals that can cause scale buildup. Additionally, acrylic acid homopolymer has the ability to disperse particulate matter, further reducing the risk of clogging and damage to the system.

One of the primary benefits of using acrylic acid homopolymer is its ability to adapt to various water conditions, including hard water, which is known to accelerate scaling. Its compatibility with different water systems makes it an excellent choice for industries that rely on cooling towers, boilers, and other water-intensive equipment. By incorporating acrylic acid homopolymer into your water treatment regimen, you can achieve optimal scale control and maintain a clean, efficient system.

Polyaspartic Acid: Advanced Protection Against Scaling and Corrosion

For a more advanced solution, polyaspartic acid has become a key player in water treatment. Known for its exceptional scale inhibition properties, polyaspartic acid prevents the formation of scale without the need for excessive chemical additives. It works by interfering with the crystallization process of minerals, thus preventing them from forming hard deposits on surfaces.

Unlike traditional inhibitors, polyaspartic acid is biodegradable, making it an environmentally friendly option. Its low toxicity and high efficiency make it ideal for use in a wide range of industries, from energy production to manufacturing. In cooling towers, where the prevention of both scale and corrosion is critical, polyaspartic acid offers a sustainable and highly effective solution for maintaining system performance and extending equipment lifespan.

Polyaspartic Acid Sodium Salt: A Cost-Effective, Sustainable Solution

An alternative to traditional chemical inhibitors, polyaspartic acid sodium salt offers the same powerful scale and corrosion inhibition properties but with the added benefit of being cost-effective and environmentally friendly. This compound works by forming a protective coating on the metal surfaces of your equipment, preventing the adhesion of scale-forming minerals.

Polyaspartic acid sodium salt is particularly effective in systems where water quality is inconsistent, as it helps to maintain optimal performance even in challenging conditions. Its ability to reduce the formation of scale and corrosion makes it a valuable addition to any water treatment system, particularly in industries that rely on cooling towers, boilers, and heat exchangers.

Scale and Corrosion Inhibitor for Cooling Tower Systems: Maintaining Efficiency

When it comes to scale and corrosion inhibitors for cooling towers, the right product can make all the difference. These systems are highly susceptible to both scale buildup and corrosion, which can severely impact their efficiency and longevity. By incorporating inhibitors like LK-1100 Modified Polyacrylic Acid, acrylic acid homopolymer, and polyaspartic acid, industries can ensure that their equipment operates at peak efficiency, reducing downtime and maintenance costs.

In addition to keeping scaling under control, these inhibitors also help prevent the corrosion of metal surfaces, which is crucial in maintaining the structural integrity of cooling towers. By preventing both scale and corrosion, industries can optimize their operations, improve energy efficiency, and extend the life of their equipment. With the right inhibitors in place, your water systems will continue to run smoothly, even under demanding conditions.

By choosing the right inhibitors, industries can achieve scale-free efficiency, improve system performance, and protect their equipment from the damaging effects of scaling and corrosion.

-

Understanding Polycarboxylic Acids: Properties, Applications, and Future PotentialNewsJul.28,2025

-

Scale Inhibitor Explained: How to Protect Your System from Limescale and Hard Water DamageNewsJul.28,2025

-

Scale and Corrosion Inhibitors: Essential Chemicals for Industrial Water System ProtectionNewsJul.28,2025

-

Polyaspartic Acid: A Biodegradable Polymer for Sustainable ChemistryNewsJul.28,2025

-

Isothiazolinones: A Versatile Antimicrobial Class with Industrial Power and Regulatory ChallengesNewsJul.28,2025

-

A Deep Dive into 2-Phosphonobutane-1,2,4-Tricarboxylic Acid (PBTC)NewsJul.28,2025