scale and corrosion inhibitor for cooling tower

Scale and Corrosion Inhibitors for Cooling Towers

Cooling towers are crucial components in various industrial applications, including power plants, chemical processing, and HVAC systems. They help dissipate heat from circulating water, ensuring efficient operation of machinery and preventing overheating. However, the operation of cooling towers is often hampered by scale formation and corrosion, which can significantly affect their efficiency and lifespan. Thus, the use of scale and corrosion inhibitors has become an essential aspect of cooling tower maintenance.

Understanding Scale Formation

Scale is a hard, mineral deposit that forms on the surfaces of cooling towers due to the evaporation of water and the precipitation of dissolved minerals, such as calcium, magnesium, and silica. As water evaporates, the concentration of these minerals increases, leading to their crystallization and subsequent deposition on heat exchange surfaces, fill materials, and other components of the cooling system. This build-up of scale can act as an insulating layer, reducing heat transfer efficiency and forcing the system to work harder, which in turn increases energy costs and operational issues.

The Impact of Corrosion

Corrosion, on the other hand, refers to the deterioration of materials, typically metals, due to chemical reactions with their environment. In cooling towers, the presence of oxygen, carbon dioxide, and other corrosive agents in water can lead to pitting, rusting, and structural failure of pipes and cooling tower materials. Corrosion not only compromises the integrity of the system but can also result in severe downtime and costly repairs.

The Role of Inhibitors

scale and corrosion inhibitor for cooling tower

To combat scale and corrosion, various inhibitors are employed in cooling tower systems. These chemical compounds are specifically designed to inhibit the formation of scale and reduce the rate of corrosion, thereby enhancing the operational efficiency and longevity of the cooling system.

1. Scale Inhibitors These substances work by interfering with the crystallization process of mineral deposits. By altering the morphology of the scale-forming crystals or suspending them in the water, scale inhibitors help keep the system free from build-up. Commonly used scale inhibitors include phosphonates, polyacrylates, and organic acids. Their effectiveness depends on dosing, water chemistry, and system conditions.

2. Corrosion Inhibitors Different types of corrosion inhibitors are available depending on the materials of construction and the specific corrosive environment within the cooling tower. Common inhibitors such as sodium nitrite, molybdate, and phosphates act by forming a protective film on metal surfaces, thereby preventing corrosive substances from causing damage. These inhibitors are particularly important for systems utilizing ferrous metals, such as steel, which are prone to corrosion.

Choosing the Right Inhibitor

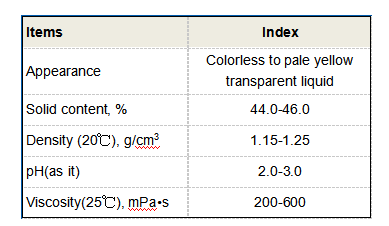

Selecting the appropriate scale and corrosion inhibitor is crucial for optimal cooling tower performance. Factors such as water chemistry, temperature, pH, and presence of other contaminants must be considered. Regular water testing and monitoring are essential to ensure that inhibitors are functioning effectively and that the cooling water remains within acceptable limits for optimal operation.

Conclusion

The importance of scale and corrosion inhibitors in cooling tower systems cannot be overstated. These compounds play a vital role in maintaining efficiency, preventing costly repairs, and ensuring the smooth operation of industrial processes. By understanding the mechanisms of scale and corrosion, facility managers can make informed decisions regarding water treatment programs and the selection of appropriate inhibitors. In doing so, they not only extend the life of the cooling equipment but also contribute to a more sustainable and energy-efficient operation. Regular maintenance and monitoring will ensure that cooling towers continue to function effectively, meeting the demands of modern industrial applications while minimizing environmental impact.

-

2 Phosphonobutane 1,2,4 Tricarboxylic Acid (PBTCA): Superior Scale & Corrosion InhibitorNewsAug.31,2025

-

Dodecyldimethylbenzylammonium Chloride: High-Purity DisinfectantNewsAug.30,2025

-

2-Phosphonobutane-1,2,4-Tricarboxylic Acid: Scale & CorrosionNewsAug.29,2025

-

Premium Isothiazolinones | Broad-Spectrum Biocidal SolutionsNewsAug.28,2025

-

LK-319 Special Scale And Corrosion Inhibitor For Steel Plants: Advanced Solutions for Industrial Water SystemsNewsAug.22,2025

-

Flocculant Water Treatment: Essential Chemical Solutions for Purification ProcessesNewsAug.22,2025