scale and corrosion inhibitor for cooling tower

Scale and Corrosion Inhibitors for Cooling Towers

Cooling towers are essential components in various industrial applications, including power plants, chemical processing, and HVAC systems. They are designed to dissipate heat from cooling water systems, ensuring efficient operation and energy conservation. However, the presence of scale and corrosion can significantly hinder the performance and longevity of these systems, leading to increased maintenance costs and reduced efficiency. Consequently, the use of appropriate scale and corrosion inhibitors is critical for the effective operation of cooling towers.

Understanding Scale and Corrosion

Scale formation generally occurs when dissolved minerals in water precipitate out, typically due to changes in temperature or concentration. Common minerals that contribute to scale include calcium, magnesium, and silica. When these mineral salts crystallize, they adhere to the surfaces of the cooling tower, heat exchangers, and piping, causing clogged systems and reduced heat transfer efficiency. In severe cases, scale can lead to equipment failure, necessitating costly repairs or replacements.

Corrosion, on the other hand, is the deterioration of materials (usually metals) due to chemical reactions with the environment. In cooling towers, corrosion can be driven by factors such as oxygen concentration, pH levels, and the presence of chlorides. Corrosion not only compromises the structural integrity of equipment but also contributes to the formation of additional deposits that further exacerbate operational issues.

The Role of Inhibitors

To combat scale and corrosion, industrial operators often resort to chemical inhibitors. These substances are designed to minimize the formation of scale and reduce the rate of corrosion, ultimately extending the life of cooling systems and enhancing operational efficiency. There are several types of inhibitors commonly used in cooling towers

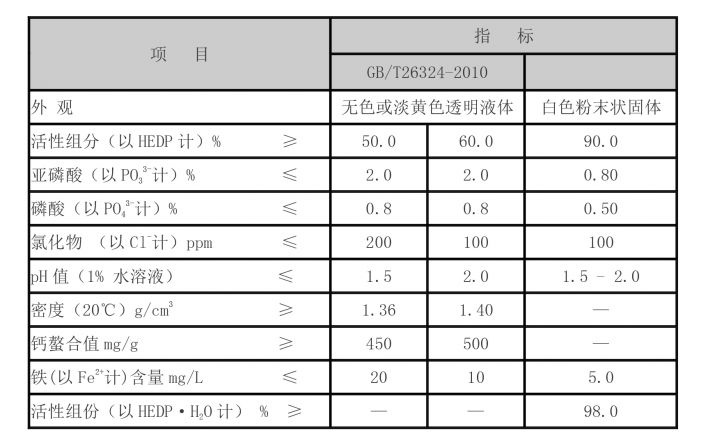

1. Scale Inhibitors These compounds work by interfering with the crystallization process of scale-forming minerals. Common scale inhibitors include polyacrylic acids, phosphonates, and polyphosphates. They can either precipitate the scale minerals into a more manageable form or keep them in suspension, preventing them from adhering to surfaces.

scale and corrosion inhibitor for cooling tower

2. Corrosion Inhibitors These chemicals function by forming a protective layer on metal surfaces, thereby reducing their exposure to corrosive agents. Common corrosion inhibitors include zinc salts, azoles, and amines. They can modify the electrochemical processes occurring on the surface of metals and help maintain the pH levels required to minimize corrosion.

3. Combined Formulations Many modern inhibitors are designed to provide both scale and corrosion protection in a single formulation, simplifying the treatment process and enhancing overall effectiveness. These combined formulations are particularly beneficial in environments where both issues are prevalent.

Selecting the Right Inhibitor

The selection of a suitable scale and corrosion inhibitor depends on various factors, including water chemistry, operational conditions (such as temperature and concentration), and environmental regulations. Conducting a thorough analysis of the water characteristics, such as hardness, alkalinity, and the presence of specific ions, is crucial for choosing the right inhibitor.

Moreover, the compatibility of the inhibitor with the cooling system materials must also be considered. Different metals react differently to various inhibitors, and selecting an incompatible product can result in more damage than benefit.

Conclusion

In summary, scale and corrosion are significant challenges faced by cooling tower systems, adversely affecting their efficiency and lifespan. The implementation of appropriate scale and corrosion inhibitors is vital for maintaining optimal operation and minimizing maintenance costs. By understanding the mechanisms of scale and corrosion, as well as selecting the right inhibitors tailored to the specific operating conditions, industries can ensure their cooling towers function efficiently and effectively over time. Investing in proper chemical treatment not only protects equipment but also contributes to sustainable practices within industrial operations.

-

Dodecyldimethylbenzylammonium Chloride: High-Purity DisinfectantNewsAug.30,2025

-

2-Phosphonobutane-1,2,4-Tricarboxylic Acid: Scale & CorrosionNewsAug.29,2025

-

Premium Isothiazolinones | Broad-Spectrum Biocidal SolutionsNewsAug.28,2025

-

LK-319 Special Scale And Corrosion Inhibitor For Steel Plants: Advanced Solutions for Industrial Water SystemsNewsAug.22,2025

-

Flocculant Water Treatment: Essential Chemical Solutions for Purification ProcessesNewsAug.22,2025

-

Isothiazolinones: Versatile Microbial Control Agents for Industrial and Consumer ApplicationsNewsAug.22,2025