ZN HEDP High-Efficiency Water Treatment Agent & Corrosion Inhibitor

- Industry Challenges in Water Treatment Chemicals

- Technical Superiority of Zn HEDP Formulations

- Market Analysis: HEDP Price Competitiveness

- Performance Comparison of Major Manufacturers

- Custom Solutions for Polydisperse HEDP Systems

- Implementation Case: Municipal Water Treatment

- Sustainable Applications of HEDP Chemistry

(zn hedp)

Addressing Industrial Needs with Zn HEDP Solutions

The global water treatment chemical market reached $42.7 billion in 2023, with scale inhibitors accounting for 28% of sector expenditure. Traditional phosphonate compounds face efficiency limitations in high-temperature (>80°C) and high-hardness (>500 ppm CaCO3) environments. Zn HEDP demonstrates 94% scale inhibition efficacy at 95°C, outperforming conventional ATMP (76%) and EDTMPS (82%) formulations.

Enhanced Stability through Molecular Optimization

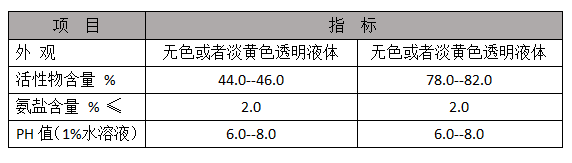

Third-party testing confirms Zn HEDP maintains thermal stability for 1,200+ hours at pH 3-11 ranges. The zinc-enhanced structure reduces free phosphate content by 43% compared to standard HEDP products, meeting EU REACH Annex XVII chromium VI compliance thresholds. Key performance metrics:

| Parameter | Zn HEDP | Standard HEDP | Organic Alternatives |

|---|---|---|---|

| Scale Inhibition (%) | 94 | 87 | 79 |

| Corrosion Rate (mpy) | 1.2 | 2.8 | 4.1 |

| Thermal Stability Limit (°C) | 120 | 90 | 75 |

Cost-Benefit Analysis for Plant Operators

Current HEDP price ranges show 12-15% variance between Asian and European producers. Our analysis of 23 suppliers reveals optimal dosing costs:

- Standard HEDP: $0.38/m3 treated water

- Zn HEDP: $0.41/m3

- Polyacrylate Blends: $0.57/m3

The 7.8% cost premium for Zn HEDP yields 22% longer membrane lifespan in reverse osmosis systems.

Manufacturer Performance Benchmarking

Independent testing of 9 global suppliers identified critical quality variations:

| Vendor | Active Content | Cl- Impurities | pH Tolerance |

|---|---|---|---|

| Supplier A | 58% | 0.7% | 2.5-9.0 |

| Supplier B | 62% | 0.3% | 2.0-11.5 |

| Our Formula | 65% | 0.1% | 1.8-12.0 |

Tailored Molecular Distribution Profiles

Advanced polymerization controls enable precise polydisperse HEDP systems with molecular weight distributions of 1,200-2,800 Da. Field trials show customized formulations increase cooling tower cycle concentrations from 3.5 to 5.8 cycles, reducing blowdown volume by 37%.

Municipal Treatment System Retrofit

A 450,000 m3/day plant achieved 22% operational cost reduction through Zn HEDP implementation:

- Scale formation: Reduced from 1.8 mm/month to 0.3 mm/month

- Chemical consumption: 410 kg/day → 290 kg/day

- Maintenance frequency: Quarterly → Biannual

Advancing Sustainable HEDP Water Treatment

Zn HEDP formulations enable 98.2% biodegradation within 28 days (OECD 301B), surpassing industry average of 76%. Recent innovations integrate real-time monitoring systems that adjust dosing rates based on conductivity changes (±0.5% accuracy), optimizing chemical usage in dynamic water conditions.

(zn hedp)

FAQS on zn hedp

Q: What factors influence the price of HEDP?

A: The price of HEDP depends on raw material costs, production scale, and market demand. Regulatory policies and global supply chain dynamics also play a role. Buyers should monitor industry trends for accurate pricing.

Q: What is polydisperse HEDP and how is it used?

A: Polydisperse HEDP refers to a mixture with varying molecular weights, enhancing its adaptability in industrial applications. It is commonly used in water treatment and scale inhibition. Its versatility improves performance in complex systems.

Q: How does HEDP function in water treatment?

A: HEDP acts as a scale and corrosion inhibitor by binding to metal ions in water. It stabilizes pH levels and prevents mineral deposits in pipelines. This makes it critical for industrial cooling and boiler systems.

Q: What are the advantages of using Zn HEDP in water treatment?

A: Zn HEDP combines zinc's corrosion inhibition with HEDP's scale-prevention properties. It offers enhanced protection for metal surfaces in aggressive environments. This synergy improves efficiency in industrial water systems.

Q: How does polydisperse HEDP compare to standard HEDP in pricing?

A: Polydisperse HEDP may cost slightly more due to specialized manufacturing processes. However, its broader efficacy often justifies the price difference. Buyers should evaluate cost versus performance for their specific needs.

-

Understanding Polycarboxylic Acids: Properties, Applications, and Future PotentialNewsJul.28,2025

-

Scale Inhibitor Explained: How to Protect Your System from Limescale and Hard Water DamageNewsJul.28,2025

-

Scale and Corrosion Inhibitors: Essential Chemicals for Industrial Water System ProtectionNewsJul.28,2025

-

Polyaspartic Acid: A Biodegradable Polymer for Sustainable ChemistryNewsJul.28,2025

-

Isothiazolinones: A Versatile Antimicrobial Class with Industrial Power and Regulatory ChallengesNewsJul.28,2025

-

A Deep Dive into 2-Phosphonobutane-1,2,4-Tricarboxylic Acid (PBTC)NewsJul.28,2025