ਜਨਃ . 31, 2025 06:22

Back to list

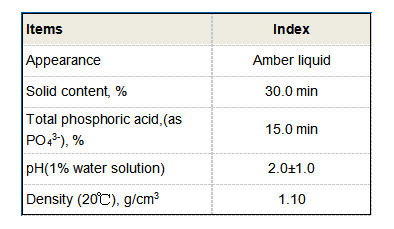

Sodium of Polyepoxysuccinic Acid (PESA)

Navigating the Complex World of OEM Flocculants An In-Depth Analysis

This level of specialization feeds directly into the broader discourse on sustainable industrial practices. By fine-tuning flocculant efficiency, the downstream impact on ecosystems and communities is significantly reduced. Fewer pollutants mean less environmental degradation, and this lies at the heart of building sustainable industrial ecosystems. As industries embrace more eco-friendly operational models, the demand for such tailored solutions is poised to rise. Furthermore, OEM flocculants are not just about enhanced performance; they also offer a profound opportunity for cost management. Industries leveraging these custom solutions often find that initial higher investments in specialized flocculants result in lower operational costs over the lifecycle of their application. Reduced chemical usage, lower disposal fees, and improved compliance with environmental regulations equate to a measurable return on investment. From an authoritative stance, leaders in the field of chemical processing and environmental management consistently advocate for the integration of OEM solutions. The customization available aligns perfectly with industry movements towards precision manufacturing and intelligent systems, concepts that are fast becoming industry standards across the globe. As technological advancements continue to intersect with the need for efficient industrial processes, the role of OEM flocculants is set to expand. In this dynamic landscape, companies must align with reputable manufacturers with proven expertise in innovation and sustainability. This partnership guarantees not only superior product performance but also aligns with global industrial strategies focusing on efficiency, environmental responsibility, and economic viability. In conclusion, while the broader category of flocculants serves an indispensable role across industries, OEM flocculants offer a subset of advanced solutions characterized by precision, adaptability, and tailored efficacy. Their integration results not just in improved performance metrics but also contributes significantly to an organization's environmental and economic goals, making them an essential component in the toolkit of modern industry leaders.

This level of specialization feeds directly into the broader discourse on sustainable industrial practices. By fine-tuning flocculant efficiency, the downstream impact on ecosystems and communities is significantly reduced. Fewer pollutants mean less environmental degradation, and this lies at the heart of building sustainable industrial ecosystems. As industries embrace more eco-friendly operational models, the demand for such tailored solutions is poised to rise. Furthermore, OEM flocculants are not just about enhanced performance; they also offer a profound opportunity for cost management. Industries leveraging these custom solutions often find that initial higher investments in specialized flocculants result in lower operational costs over the lifecycle of their application. Reduced chemical usage, lower disposal fees, and improved compliance with environmental regulations equate to a measurable return on investment. From an authoritative stance, leaders in the field of chemical processing and environmental management consistently advocate for the integration of OEM solutions. The customization available aligns perfectly with industry movements towards precision manufacturing and intelligent systems, concepts that are fast becoming industry standards across the globe. As technological advancements continue to intersect with the need for efficient industrial processes, the role of OEM flocculants is set to expand. In this dynamic landscape, companies must align with reputable manufacturers with proven expertise in innovation and sustainability. This partnership guarantees not only superior product performance but also aligns with global industrial strategies focusing on efficiency, environmental responsibility, and economic viability. In conclusion, while the broader category of flocculants serves an indispensable role across industries, OEM flocculants offer a subset of advanced solutions characterized by precision, adaptability, and tailored efficacy. Their integration results not just in improved performance metrics but also contributes significantly to an organization's environmental and economic goals, making them an essential component in the toolkit of modern industry leaders.

Share

Next:

Latest news

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025