Exploring the Applications and Benefits of Cationic Polyacrylamide in Various Industries

The Role of Cationic Polyacrylamide in Modern Industry

Cationic polyacrylamide (CPAM) is a water-soluble polymer that has gained significant traction in various industrial and environmental applications due to its unique properties. As a derivative of polyacrylamide, CPAM contains positively charged functional groups, which enhances its performance in a myriad of uses, particularly in water treatment, papermaking, and oil recovery.

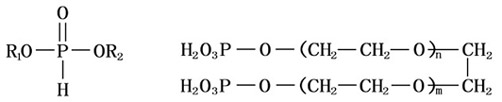

Structure and Properties

Cationic polyacrylamide is synthesized through the polymerization of acrylamide monomers, introducing cationic groups into the polymer chain. The presence of these cationic groups influences its solubility and interaction with other substances in a solution. One of the most notable characteristics of CPAM is its ability to flocculate (or aggregate) particles in water, which is a crucial feature utilized in various processes. Its molecular weight can vary widely, allowing it to be tailored for specific applications, from low molecular weight for rapid flocculation to high molecular weight for enhanced viscosity and water retention.

Applications in Water Treatment

One of the primary applications of cationic polyacrylamide is in the field of water treatment. In municipal and industrial wastewater treatment plants, CPAM acts as a flocculant to remove suspended solids and emulsified oils from water. By neutralizing the negative charges of particles, it facilitates the formation of larger aggregates, or flocs, that can then be more easily removed from the water. This property is critical for maintaining water quality and meeting regulatory standards, thereby contributing to environmental sustainability.

Moreover, CPAM is used in sludge dewatering processes

. By enhancing the dewatering efficiency, it reduces the volume of sludge that needs to be disposed of, minimizing disposal costs and environmental impacts. The use of cationic polyacrylamide in these applications not only improves the efficiency of water treatment processes but also contributes to the reduction of the ecological footprint of industrial activities.cationic polyacrylamide

Role in Papermaking

In the papermaking industry, CPAM serves as a retention and drainage aid. It helps improve the retention of fine particles and fillers, enhancing the quality and strength of the final product. By facilitating better water removal during the papermaking process, CPAM increases production efficiency and reduces energy consumption. The use of cationic polyacrylamide in this industry exemplifies how this polymer can enhance performance while simultaneously promoting cost-effectiveness.

Application in Enhanced Oil Recovery

Cationic polyacrylamide is also gaining attention in the oil and gas industry, particularly in enhanced oil recovery (EOR) techniques. Its ability to modify the viscosity of water solutions makes it a suitable candidate for polymer flooding operations. By injecting CPAM into reservoirs, operators can improve the viscosity of the water used in EOR processes, which enhances oil displacement and ultimately increases hydrocarbon recovery rates. This application highlights the versatility of CPAM and its importance in maximizing resource extraction efficiency.

Conclusion

Cationic polyacrylamide is a multifaceted polymer that plays a vital role in various industrial applications, from water treatment and papermaking to oil recovery. Its unique properties, particularly its ability to flocculate particles and enhance fluid characteristics, make it an invaluable asset in improving operational efficiencies and meeting stringent environmental regulations. As industries continue to seek sustainable solutions, CPAM will undoubtedly remain a key player in driving innovation and efficiency across multiple sectors. The ongoing research into its applications and improvements ensures that cationic polyacrylamide is well-positioned for continued relevance in the future.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025