industrial flocculant

The Role of Industrial Flocculants in Water Treatment and Waste Management

Industrial flocculants play a crucial role in water treatment and waste management processes, proving to be essential components in various industries. These chemical agents facilitate the aggregation of suspended particles in liquid environments, enhancing sedimentation and filtration processes, and thereby improving water clarity and quality.

Understanding Flocculants

Flocculants are substances that promote the clumping together of particles, or flocculation, which allows them to settle out of suspension in a liquid. They are commonly used in a variety of applications, including municipal water treatment, industrial wastewater management, mineral processing, and even in the pulp and paper industry. Flocculants can be ionic or non-ionic, and they can be derived from natural sources such as starch and alginates, or they can be synthetic polymers designed for specific tasks.

Mechanism of Action

The mechanism through which flocculants operate involves the neutralization of the electrostatic charges that keep particles suspended in water. When suspended particles are positively charged, they repel one another. Flocculants, when added to the mixture, typically carry a charge that can neutralize the surface charges of these particles. This neutralization allows particles to come together and form larger aggregates or flocs that are heavy enough to settle at the bottom of the tank.

The efficiency of flocculants can be influenced by several factors, including pH levels, temperature, and the presence of other chemicals in the solution. Therefore, careful selection and dosage of flocculants are crucial for optimizing performance in each specific application.

Applications in Water Treatment

industrial flocculant

In municipal water treatment, flocculants are essential for removing impurities and contaminants from water sources before they reach consumers. This process not only ensures compliance with safety standards but also contributes to the overall reduction of harmful pollutants in aquatic environments.

In industrial settings, flocculants are vital during the treatment of wastewater that may contain heavy metals, oils, and other toxic substances. Effective flocculation helps to minimize the environmental impact of wastewater discharge, enabling companies to adhere to regulatory requirements and promote sustainable practices.

In the mining industry, flocculants aid in the separation of valuable minerals from ore, enhancing recovery rates and reducing the volume of waste. This application supports both economic efficiency and environmental stewardship, as better resource management reduces the ecological footprint of mining operations.

Advantages of Using Flocculants

The use of flocculants brings numerous advantages. Firstly, they significantly improve settling rates in both water treatment and industrial processes, leading to reduced operational costs and increased efficiency. As flocculants facilitate clear liquid separation, they also enhance the quality of treated water, making it suitable for various uses, including reuse and recycling.

Additionally, the implementation of flocculants can help reduce the amount of chemicals needed in processes, fostering a greener approach to industrial practices. This contributes to lower overall chemical costs and a diminished environmental impact.

Conclusion

In conclusion, industrial flocculants serve as indispensable tools in the realm of water treatment and waste management. Their ability to enhance the clarity and quality of water, coupled with their benefits in various industries, underscores their importance in promoting environmentally friendly practices. As industries continue to seek sustainable solutions to address water quality and environmental challenges, flocculants will likely remain at the forefront of innovative technologies aimed at achieving these goals. The future of water treatment relies not only on traditional methods but also on the continued development and application of effective flocculant technologies.

-

LK-319 Special Scale And Corrosion Inhibitor For Steel Plants: Advanced Solutions for Industrial Water SystemsNewsAug.22,2025

-

Flocculant Water Treatment: Essential Chemical Solutions for Purification ProcessesNewsAug.22,2025

-

Isothiazolinones: Versatile Microbial Control Agents for Industrial and Consumer ApplicationsNewsAug.22,2025

-

Scale Inhibitor: Key Solutions for Water System Scale PreventionNewsAug.22,2025

-

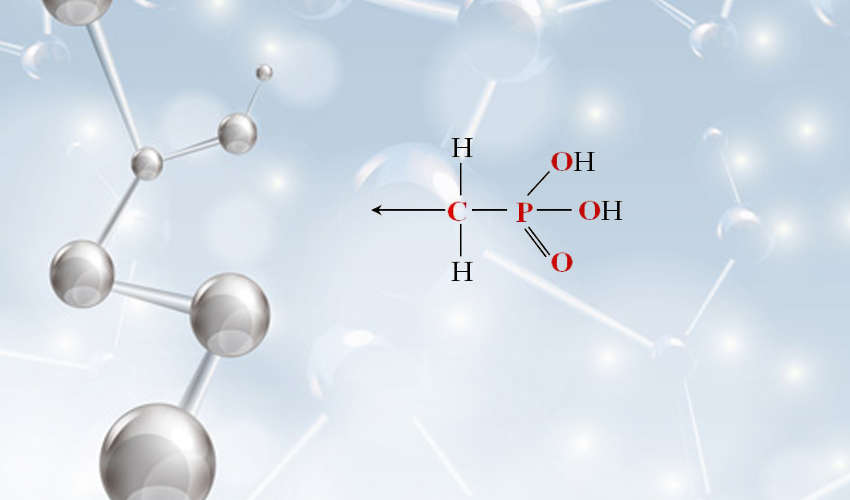

Organophosphonates: Versatile Scale Inhibitors for Industrial Water SystemsNewsAug.22,2025

-

Scale and Corrosion Inhibitor: Essential Chemical Solutions for Water System MaintenanceNewsAug.22,2025