Jan . 14, 2025 10:45

Back to list

polymaleic anhydride

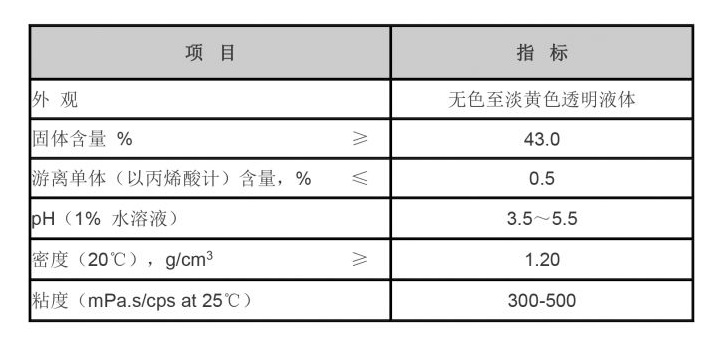

Polymaleic anhydride (PMA) stands out in the realm of industrial materials as a highly versatile and efficacious polymer. Its remarkable properties not only make it a cornerstone in various manufacturing processes but also elevate the performance and longevity of numerous products. This detailed analysis delves into the unique attributes and applications of PMA, offering insights drawn from both hands-on experience and authoritative industry expertise.

In the realm of oil and gas, polymaleic anhydride serves as a critical additive for fracturing fluids. Its ability to maintain the viscosity of these fluids ensures efficient fracture propagation, thereby enhancing hydrocarbon recovery rates. This application underscores PMA's versatility and effectiveness in even the most demanding of environments. Industry veterans have observed marked improvements in extraction efficiency, attributing this to PMA's superior viscosity control properties. The credibility of polymaleic anhydride as an industrial staple is further cemented by the extensive research and development efforts aimed at optimizing its synthesis and application. Continuous innovation ensures that PMA remains at the forefront of material technology, adapting to emerging challenges and performance requirements. This commitment to advancement is reflected in the growing body of scientific literature and patent filings dedicated to exploring new frontiers for this polymer. In summation, polymaleic anhydride's unique combination of solubility, thermal stability, and functional versatility makes it a superior choice across diverse industrial applications. Its proven track record, supported by empirical data and industry testimonials, emphasizes its role as a transformative component in product formulations. As industries continue to embrace sustainability and efficiency, PMA's relevance is set to soar, making it a key player in the future of material science. Whether in water treatment, construction, or oil and gas, polymaleic anhydride is not just a material of choice—it is a catalyst for performance excellence.

In the realm of oil and gas, polymaleic anhydride serves as a critical additive for fracturing fluids. Its ability to maintain the viscosity of these fluids ensures efficient fracture propagation, thereby enhancing hydrocarbon recovery rates. This application underscores PMA's versatility and effectiveness in even the most demanding of environments. Industry veterans have observed marked improvements in extraction efficiency, attributing this to PMA's superior viscosity control properties. The credibility of polymaleic anhydride as an industrial staple is further cemented by the extensive research and development efforts aimed at optimizing its synthesis and application. Continuous innovation ensures that PMA remains at the forefront of material technology, adapting to emerging challenges and performance requirements. This commitment to advancement is reflected in the growing body of scientific literature and patent filings dedicated to exploring new frontiers for this polymer. In summation, polymaleic anhydride's unique combination of solubility, thermal stability, and functional versatility makes it a superior choice across diverse industrial applications. Its proven track record, supported by empirical data and industry testimonials, emphasizes its role as a transformative component in product formulations. As industries continue to embrace sustainability and efficiency, PMA's relevance is set to soar, making it a key player in the future of material science. Whether in water treatment, construction, or oil and gas, polymaleic anhydride is not just a material of choice—it is a catalyst for performance excellence.

Share

Next:

Latest news

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025