industrial flocculant

Industrial Flocculants An Overview and Their Applications

Flocculants are chemical substances that promote the agglomeration of particles suspended in a liquid, leading to the formation of flocs, or larger aggregates. They play a crucial role in various industrial processes, particularly in the fields of water treatment, mining, and paper manufacturing. By enhancing sedimentation, flocculants improve the efficiency of separation processes, leading to significant economic and environmental benefits.

Types of Flocculants

Flocculants can be classified into several categories based on their composition and mechanism of action. The most common types include

1. Natural Flocculants These include materials derived from natural sources, such as starch, guar gum, and alginates. They are often biodegradable and considered environmentally friendly. However, their effectiveness can vary depending on the composition of the wastewater.

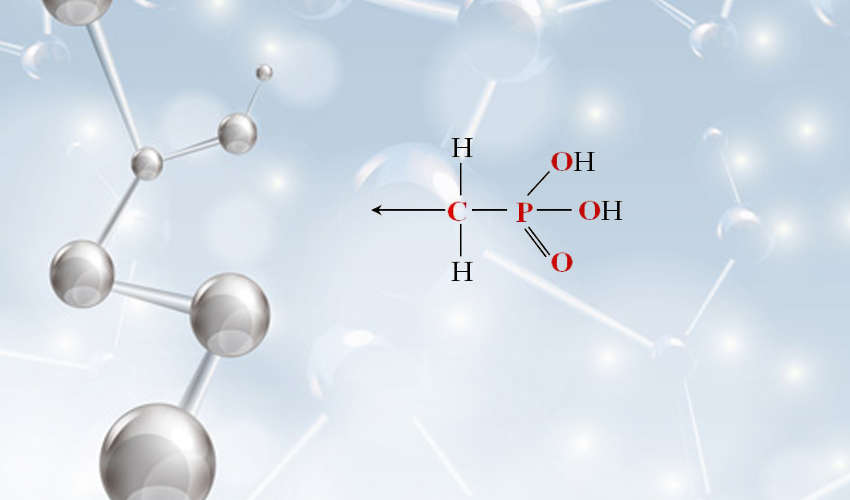

2. Synthetic Flocculants These are chemical compounds manufactured through industrial processes. Synthetic flocculants are typically more effective than their natural counterparts, as they can be tailored to specific applications. Common types include polyacrylamides, polyethylene oxide, and polyamines. Among these, anionic and cationic polyacrylamides are widely used due to their superior flocculation properties.

3. Inorganic Flocculants Materials such as alum (aluminum sulfate) and ferric chloride fall into this category. Inorganic flocculants are often used in municipal water treatment facilities, as they are effective in removing suspended solids and pathogens from water.

Applications of Flocculants

One of the most significant applications of flocculants is in water treatment. Flocculants are added to drinking water and wastewater treatment processes to remove impurities. The process typically involves the addition of a flocculant to the water, which encourages suspended solids to clump together, making them easier to filter out. This is especially important for municipal water supplies, where the quality and safety of drinking water are paramount.

industrial flocculant

2. Mining Industry

In the mining sector, flocculants are critical in ore processing and tailings management. During mineral processing, valuable minerals are separated from the ore, resulting in a mixture of solids and water. The addition of flocculants aids in the sedimentation of the solids, allowing for the separation and recovery of valuable minerals. In tailings management, flocculants help reduce the volume of waste generated, thereby minimizing environmental impact and promoting sustainable practices.

3. Paper Manufacturing

In the paper industry, flocculants are used to enhance the formation of paper sheets. They help in the retention of fibers and fillers, which contribute to the strength and quality of the final product. Additionally, flocculants assist in the removal of contaminants during the pulping process, resulting in a clearer and purer paper product.

Environmental Considerations

While flocculants serve significant roles in various industries, their environmental impact cannot be overlooked. The use of synthetic flocculants, particularly polyacrylamides, raises concerns about potential toxicity and bioaccumulation in aquatic environments. Therefore, it is essential for industries to assess the ecological implications of flocculants and consider alternative options, such as natural flocculants, wherever feasible.

Moreover, regulations surrounding wastewater discharge are becoming more stringent. Industries must ensure that their flocculation processes comply with environmental standards and do not introduce harmful substances into the ecosystem.

Conclusion

Industrial flocculants are vital compounds that facilitate numerous processes across different sectors, particularly in water treatment, mining, and paper manufacturing. Their ability to promote the agglomeration of suspended particles enhances efficiency and resource recovery, contributing to both economic and environmental sustainability. As industries strive to minimize their ecological footprints, the continuous development of environmentally friendly flocculants will be crucial. Embracing innovative technologies and practices can lead to a future where industrial efficiency coexists harmoniously with environmental stewardship.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025