poly aluminum chloride manufacturer

Poly Aluminum Chloride The Essential Coagulant and Its Manufacturers

Poly Aluminum Chloride (PAC) is a versatile and widely used coagulant in various water treatment processes. As a crucial component in drinking water purification, wastewater treatment, and industrial applications, PAC has gained significant attention from manufacturers around the globe. This article delves into the nature of PAC, its applications, and the factors to consider when selecting a manufacturer.

What is Poly Aluminum Chloride?

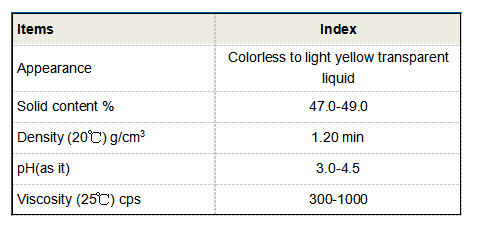

Poly Aluminum Chloride is an inorganic polymer formed by the hydrolysis of aluminum chloride in water. It appears as a pale yellow or white powder and is known for its high efficiency in coagulation and flocculation processes. PAC is a preferred coagulant due to its excellent solubility in water, lower sludge production, and its ability to operate effectively in various pH conditions.

Applications of PAC

1. Drinking Water Treatment PAC is predominantly used in the purification of drinking water. Its coagulating properties help remove suspended particles, colloids, and turbidity, ensuring that the water meets safety and aesthetic standards. The effectiveness of PAC in this application is evident in many municipal water treatment facilities.

2. Wastewater Treatment In wastewater treatment plants, PAC plays a vital role in treating industrial effluents and municipal wastewater. It aids in the removal of pollutants, heavy metals, and organic materials, thus facilitating compliance with environmental regulations.

3. Paper and Pulp Industry PAC is also extensively used in the paper and pulp industry. It acts as a sizing agent and helps improve the quality of paper, enhancing its durability and strength.

4. Cosmetics and Pharmaceuticals The versatility of PAC extends to the cosmetics and pharmaceutical industries, where it is used as an emulsifier, stabilizer, and thickening agent.

5. Food Industry In the food processing industry, PAC is used for clarification in beverages like fruit juices and wines, ensuring clarity and stability in the final product.

Selecting a Poly Aluminum Chloride Manufacturer

poly aluminum chloride manufacturer

When it comes to choosing a PAC manufacturer, several factors should be considered to ensure quality, reliability, and compliance with safety standards

.1. Quality of Product It is essential to select a manufacturer that adheres to international quality standards. Look for certifications like ISO 9001, which indicates a commitment to quality management.

2. Production Capacity Assess the manufacturer’s production capacity to ensure they can meet your demand. This is particularly important for large-scale applications.

3. Technical Support A good manufacturer should offer technical support and assistance to help optimize the dosage and application of PAC in specific processes.

4. Customization Some manufacturers provide customized products tailored to meet specific requirements of different industries. This flexibility can be beneficial depending on your needs.

5. Environmental Compliance Ensure that the manufacturer follows environmental regulations and practices sustainable manufacturing processes. This is crucial for minimizing the ecological footprint of PAC production.

6. Reputation and Experience Consider manufacturers with a solid reputation and extensive experience in the industry. Reading customer reviews and testimonials can provide insight into their reliability and product performance.

7. Pricing While cost should not be the sole deciding factor, it is important to compare prices among different manufacturers while considering the quality of their product. A cost-effective solution can significantly impact your overall operational expenses.

Conclusion

Poly Aluminum Chloride is an indispensable material in the field of water treatment and various industrial processes. Its effectiveness, coupled with its role in improving environmental safety standards, makes it a preferred choice for many applications. By carefully selecting a reputable PAC manufacturer, businesses can ensure they invest in high-quality products that meet their operational needs. As the demand for clean water continues to grow, the role of PAC and its manufacturers will remain crucial in achieving sustainable and effective water treatment solutions.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025