Optimizing Scale Control and Corrosion Protection in Cooling Tower Systems for Enhanced Efficiency

Scale and Corrosion Inhibitors for Cooling Towers

Cooling towers are critical components in various industrial processes, particularly in power generation, chemical manufacturing, and HVAC systems. They play a vital role in heat rejection by dissipating heat from a process fluid to the atmosphere. However, the efficiency and longevity of cooling towers can be significantly hindered by the formation of scale and the onset of corrosion. To mitigate these issues, the use of scale and corrosion inhibitors has become a standard practice within the industry.

Understanding Scale Formation

Scale is primarily formed when dissolved minerals in water, such as calcium, magnesium, and silica, concentrate due to evaporation. As water evaporates in cooling towers, these minerals can precipitate and deposit on heat exchange surfaces, leading to thermal insulation and reduced heat transfer efficiency. The presence of scale can elevate energy costs, reduce operational efficiency, and ultimately lead to equipment failure if not managed properly.

Corrosion Challenges

Corrosion, on the other hand, is a process that deteriorates metals and can occur due to several factors, including dissolved oxygen, low pH levels, or the presence of aggressive ions in the water. Corrosive attacks can lead to structural weaknesses in cooling tower components, resulting in leaks, system shutdowns, and costly repairs. The economic impact of corrosion alone is substantial, with industries investing millions annually in repair and maintenance.

Role of Inhibitors

scale and corrosion inhibitor for cooling tower

To combat the issues of scale and corrosion, various chemical inhibitors are employed. These inhibitors can be broadly categorized into two groups scale inhibitors and corrosion inhibitors.

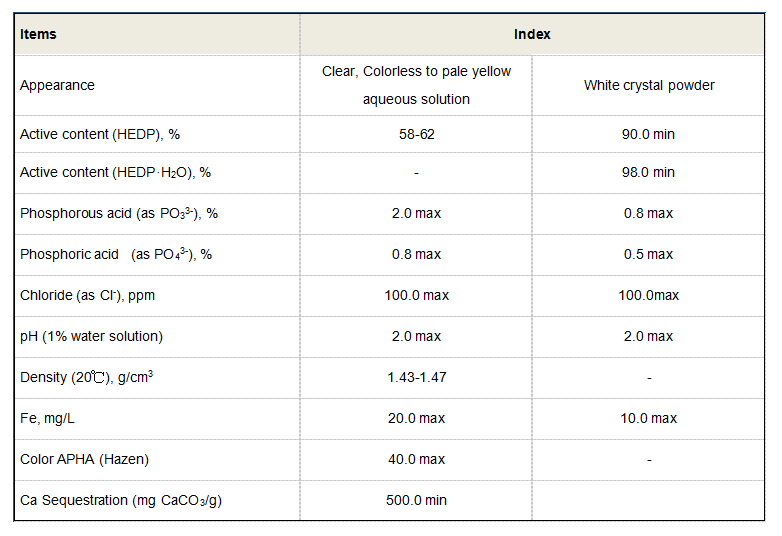

1. Scale Inhibitors These chemicals function by interfering with the crystallization process of minerals. Common examples include polyacrylic acids, phosphonates, and organic phosphates. They work by increasing the solubility of the minerals in the water, therefore preventing them from precipitating and forming scale deposits. Effective scale inhibitors can lead to extended cleaning intervals for cooling towers and improved overall efficiency.

2. Corrosion Inhibitors Corrosion inhibitors are substances that, when added to a corrosive environment, reduce the rate of corrosion of metal surfaces. These inhibitors can work through different mechanisms, such as forming a protective film on the metal surface or modifying the water chemistry to create less aggressive conditions. Commonly used corrosion inhibitors include nitrites, azoles, and phosphates. These inhibitors protect vital components, thereby prolonging the lifespan of cooling systems.

Monitoring and Management

The effectiveness of these inhibitors depends on proper dosage, monitoring, and maintenance. Regular water analysis is essential to understand the specific conditions within the cooling tower system, allowing for the adjustment of inhibitor concentrations to match the prevalent issues. Advanced monitoring systems can help in detecting changes in water chemistry and the performance of inhibitors.

Conclusion

In conclusion, the utilization of scale and corrosion inhibitors in cooling towers is a critical aspect of ensuring efficient and prolonged operation. These chemical solutions not only help in maintaining optimal heat transfer rates but also prevent costly repairs associated with scale-related inefficiencies and corrosion damage. As industries continue to push for greater efficiency and sustainability, the importance of effective water treatment programs that incorporate these inhibitors cannot be overstated. Proper management and the strategic application of scale and corrosion inhibitors are essential for the operational health of cooling towers, ultimately leading to reduced costs and enhanced performance.

-

The Power of Isothiazolinones in Modern ApplicationsNewsMay.08,2025

-

Flocculants in Water TreatmentNewsMay.08,2025

-

Flocculants and Chemical Solutions: What You Need to KnowNewsMay.08,2025

-

Flocculants and Chemical Solutions: A Growing IndustryNewsMay.08,2025

-

Essential Chemicals: Polymaleic Anhydride and MoreNewsMay.08,2025

-

Acrylic Polymers: Essential Solutions for IndustryNewsMay.08,2025