Impact of Corrosion and Scale Inhibitors on Industrial Equipment Performance and Longevity

Corrosion and Scale Inhibitors Protecting Infrastructure and Equipment

Corrosion and scaling are two significant challenges faced by various industries, particularly in sectors such as oil and gas, water treatment, and manufacturing. These phenomena not only compromise the structural integrity and efficiency of equipment but also lead to substantial economic losses. To mitigate these issues, the use of corrosion and scale inhibitors has become essential.

Understanding Corrosion and Scale Formation

Corrosion refers to the gradual breakdown of materials, typically metals, due to chemical reactions with their environment. It can occur through various processes, including oxidation, galvanic corrosion, and pitting. Factors such as moisture, oxygen, temperature, and the presence of aggressive ions exacerbate the rate of corrosion. On the other hand, scaling is the deposition of mineral salts that accumulate on surfaces, usually resulting from evaporation or changes in temperature and pressure in fluids. Commonly found in water systems, scaling can drastically reduce the efficiency of heat exchangers and boilers, leading to increased energy consumption and operational costs.

The Role of Inhibitors

Corrosion and scale inhibitors play a crucial role in protecting equipment and infrastructure. Corrosion inhibitors often work by forming a protective film on the surface of metals, thereby preventing corrosive agents from coming into contact with the underlying material. These inhibitors can be classified into several categories, including anodic inhibitors, cathodic inhibitors, and mixed inhibitors, each functioning through different mechanisms.

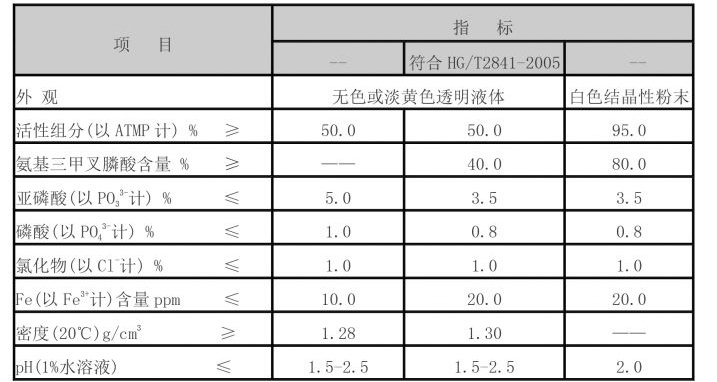

Scale inhibitors, on the other hand, work to disrupt the crystallization process of minerals or modify the physical properties of the scales to facilitate their removal. They typically include polymers, phosphonates, and other organic compounds that alter the properties of scaling minerals, thereby preventing them from adhering to surfaces.

Types of Corrosion and Scale Inhibitors

1. Corrosion Inhibitors - Anodic Inhibitors These substances reduce the rate of the anodic reaction, which involves the loss of electrons from the metal. - Cathodic Inhibitors They work by suppressing cathodic reactions, which are typically associated with the gain of electrons. - Mixed Inhibitors These compounds can simultaneously affect both anodic and cathodic reactions, providing comprehensive protection.

corrosion & scale inhibitors

2. Scale Inhibitors - Threshold Inhibitors These work by preventing scale formation at low concentrations, altering the crystallization process of scale-forming minerals. - Polymeric Inhibitors They interfere with the growth of scale crystals and facilitate their dispersion in the fluid.

Application of Inhibitors in Industry

In industrial applications, the choice of appropriate inhibitors is critical. For instance, in the oil and gas sector, the selection of the right corrosion inhibitor can prevent costly pipeline failures and extend equipment lifespan. In water treatment plants, scale inhibitors are vital to maintain efficient operation and reduce maintenance costs associated with scale buildup in boilers and cooling towers.

Furthermore, these inhibitors are not merely reactive solutions to existing problems. Instead, they are integral components of preventive maintenance strategies. Regular monitoring and dosage adjustments based on system conditions can optimize their effectiveness, ensuring long-term protection against corrosion and scaling.

Environmental Considerations

With growing environmental concerns, the development and use of eco-friendly inhibitors have gained attention. Many industries are exploring biodegradable options that minimize environmental impact while maintaining effectiveness. Regulatory standards are also influencing the choice of inhibitors, pushing for the adoption of less harmful chemicals that can still deliver robust performance.

Conclusion

Corrosion and scale inhibitors are indispensable in various industrial applications, ensuring the longevity and efficiency of equipment and infrastructure. As industries continue to evolve, the development of more effective and environmentally friendly inhibitors will be crucial in addressing these persistent challenges. By investing in proper inhibitor strategies, businesses can not only protect their assets but also contribute to sustainability and cost-efficiency in their operations.

-

lk-319-special-scale-and-corrosion-inhibitor-for-steel-plants-advanced-solutions-for-industrial-water-systemsNewsAug.22,2025

-

flocculant-water-treatment-essential-chemical-solutions-for-purification-processesNewsAug.22,2025

-

isothiazolinones-versatile-microbial-control-agents-for-industrial-and-consumer-applicationsNewsAug.22,2025

-

scale-inhibitor-key-solutions-for-water-system-scale-preventionNewsAug.22,2025

-

organophosphonates-versatile-scale-inhibitors-for-industrial-water-systemsNewsAug.22,2025

-

scale-and-corrosion-inhibitor-essential-chemical-solutions-for-water-system-maintenanceNewsAug.22,2025