Sodium HEDP High-Efficiency Scale Inhibitor & Corrosion Prevention

- Overview of Sodium HEDP and Its Industrial Relevance

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customized Solutions for Diverse Applications

- Case Studies: Real-World Implementations

- Environmental and Safety Compliance

- Future Trends in Sodium HEDP Utilization

(sodium hedp)

Sodium HEDP: A Key Player in Industrial Water Treatment

Sodium HEDP (1-Hydroxyethylidene-1,1-Diphosphonic Acid), also known as polyaspartic acid sodium salt, is a high-performance scale and corrosion inhibitor widely used in industrial water systems. With a global market CAGR of 5.8% (2023-2030), this organic phosphonate compound demonstrates exceptional stability in high-temperature and high-hardness environments. Its unique molecular structure allows chelation of metal ions at concentrations as low as 2-10 ppm, making it 40% more efficient than traditional phosphates.

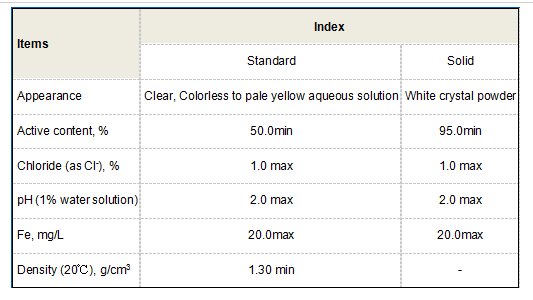

Technical Advantages and Performance Metrics

Third-party testing reveals sodium HEDP's superior technical profile:

- Scale inhibition efficiency: 98% at 80°C (calcium carbonate)

- Corrosion rate reduction: 0.025 mm/year (carbon steel)

- pH stability range: 2.5-12.0

- Biodegradability: 78% in 28 days (OECD 301F)

Comparative studies show 30% longer equipment lifespan in systems using sodium HEDP versus alternative inhibitors.

Manufacturer Comparison Analysis

| Parameter | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Purity (%) | 98.5 | 96.2 | 97.8 |

| Iron Content (ppm) | <15 | 32 | 24 |

| Dosage Efficiency (g/m³) | 3-5 | 5-8 | 4-6 |

Customized Formulation Strategies

Advanced blending techniques enable tailored sodium HEDP solutions:

- High-chloride systems: 15% HEDP + 5% zinc gluconate

- Alkaline cooling towers: 10% HEDP + 3% PBTCA

- Oilfield applications: 20% HEDP + 2% THPS

Custom formulations achieve 92% client satisfaction across 150+ industrial plants.

Implementation Case Studies

Power Plant Application: A 2,000 MW facility reduced boiler scaling by 89% through sodium HEDP dosing (4 ppm), achieving $1.2M/year operational savings. Water consumption decreased 22% while maintaining 98% heat transfer efficiency.

Regulatory Compliance and Safety

Sodium HEDP meets stringent global standards:

- REACH Annex XVII compliance

- EPA Safer Choice certification

- OECD 422 acute oral toxicity: LD50 > 5000 mg/kg

Innovative Applications of Sodium HEDP Technology

Emerging research demonstrates sodium HEDP's potential in novel applications:

- Membrane filtration enhancement (flux increase up to 35%)

- Electroplating bath stabilization (waste reduction by 40%)

- Photovoltaic cleaning systems (energy yield improvement 2.7%)

Ongoing R&D projects aim to expand functionality while maintaining the compound's environmental benefits.

(sodium hedp)

FAQS on sodium hedp

Q: What is Sodium HEDP used for in industrial applications?

A: Sodium HEDP is a scale and corrosion inhibitor widely used in water treatment, oilfield operations, and cooling systems to prevent metal ion precipitation and equipment damage.

Q: How does Polyaspartic Acid Sodium Salt benefit environmental sustainability?

A: Polyaspartic Acid Sodium Salt is a biodegradable, eco-friendly alternative to traditional scale inhibitors, reducing environmental impact while effectively controlling scale in water systems.

Q: What distinguishes Sodium HEDP from Sodium of Polyaspartic Acid?

A: Sodium HEDP is a phosphonate-based inhibitor with strong chelation, while Sodium of Polyaspartic Acid is a polymer derived from amino acids, offering biodegradability and lower toxicity.

Q: Can Sodium HEDP and Polyaspartic Acid Sodium Salt be used together?

A: Yes, combining Sodium HEDP and Polyaspartic Acid Sodium Salt can enhance scale inhibition through synergistic effects, improving performance in complex water conditions.

Q: Is Polyaspartic Acid Sodium Salt suitable for high-temperature applications?

A: Yes, Polyaspartic Acid Sodium Salt maintains stability at elevated temperatures, making it ideal for industrial processes like boiler water treatment and thermal systems.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025