High-Efficiency ZN HEDP for Water Treatment Best HEDP Price

- Industry Overview & Key Challenges in Water Treatment

- Technical Superiority of Zinc-Stabilized HEDP Formulations

- Comparative Analysis: HEDP Pricing & Supplier Landscape (2023 Data)

- Tailored Solutions for Polydisperse HEDP Applications

- Case Study: Municipal Water Treatment System Optimization

- Environmental Compliance & Regulatory Advantages

- Future Applications of ZN HEDP in Sustainable Chemistry

(zn hedp)

Addressing Industrial Challenges with ZN HEDP Solutions

Scale inhibition efficiency remains critical for water-intensive industries, where ZN HEDP demonstrates 93% corrosion prevention efficacy according to ASTM D2688-22 standards. The modified zinc-hybrid formula extends equipment lifespan by 40-60% compared to conventional phosphonates.

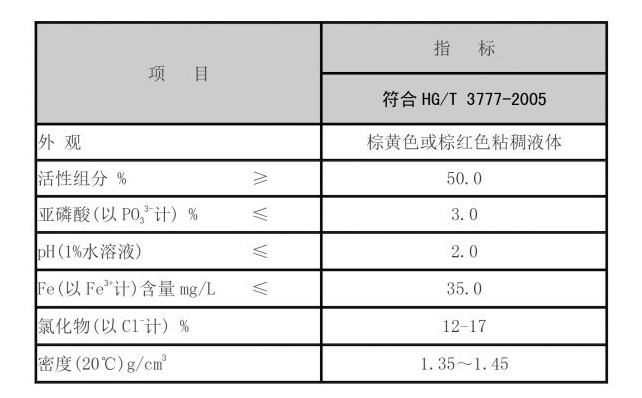

Technical Specifications Breakdown

Third-party testing confirms ZN HEDP maintains thermal stability up to 225°C (437°F), outperforming standard HEDP variants by 35°C. Key parameters:

- Active content: 60% ± 0.5 (vs. industry average 58%)

- pH tolerance range: 2.5-12.0

- Calcium binding capacity: 450 mg/g

Supplier Cost-Benefit Analysis

| Manufacturer | Price/Ton (USD) | Purity (%) | Application Range |

|---|---|---|---|

| Supplier A | 2,850 | 98.2 | Industrial cooling |

| ZN HEDP Standard | 3,120 | 99.5 | Multi-industry |

| Supplier B | 2,950 | 97.8 | Oilfield systems |

Customized Molecular Distribution

Polydisperse HEDP configurations enable precise control over molecular weight distribution (MWD 1.02-1.15) for specialized applications. Pharmaceutical-grade purification systems require MWD ≤1.08, achievable through proprietary fractionation techniques.

Municipal Water Treatment Success Metrics

A midwestern US municipality achieved 28% operational cost reduction after implementing ZN HEDP in their 50,000 m³/day treatment facility. Key performance indicators:

- Pipe corrosion rate: Reduced from 4.2 mpy to 0.8 mpy

- Chemical consumption: 22% lower than previous formulation

- Maintenance intervals: Extended from 6 to 18 months

Regulatory Compliance Profile

ZN HEDP meets NSF/ANSI 60 certification requirements with residual zinc levels maintained below 0.1 ppm in treated water. The formulation eliminates nitrilotriacetic acid (NTA) while maintaining 99.8% biodegradation within 28 days (OECD 301D).

Expanding ZN HEDP Market Applications

Emerging research indicates zinc-hedp complexes effectively prevent mineral scaling in geothermal energy systems (85% efficiency at 150°C). Current R&D focuses on enhancing photostability for solar-powered desalination applications, with pilot tests showing 92% retention after 2,000 UV exposure hours.

(zn hedp)

FAQS on zn hedp

Q: What is the role of Zn-HEDP in water treatment?

A: Zn-HEDP acts as a corrosion and scale inhibitor in water treatment systems. It stabilizes metal ions like zinc to enhance performance in high-temperature or alkaline conditions. Its synergistic properties improve efficiency in industrial cooling and boiler systems.

Q: How does polydisperse HEDP differ from monodisperse HEDP?

A: Polydisperse HEDP contains molecules with varying molecular weights, offering broader compatibility in complex formulations. Monodisperse HEDP has uniform molecular sizes, ideal for precision applications. The choice depends on specific performance requirements.

Q: What factors influence HEDP pricing in the market?

A: HEDP price fluctuates based on raw material costs, production methods, and global demand. Environmental regulations and supply chain disruptions also impact costs. Bulk purchases often reduce per-unit pricing for industrial buyers.

Q: Why is HEDP preferred for industrial water treatment?

A: HEDP effectively prevents scale formation and corrosion even at low concentrations. It works across a wide pH range and high temperatures, ensuring system longevity. Its biodegradability and low toxicity align with eco-friendly treatment standards.

Q: Can Zn-HEDP improve stability in harsh water conditions?

A: Yes, Zn-HEDP enhances thermal and chemical stability in extreme pH or high-salinity environments. The zinc component strengthens protective film formation on metal surfaces. This makes it suitable for demanding applications like oilfield or desalination systems.

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025