Feb . 01, 2025 04:17

Back to list

industrial flocculant

In the realm of industrial water treatment, the use of flocculants has become indispensable for various sectors, including mining, food processing, and wastewater management. Industrial flocculants are chemical compounds that facilitate the agglomeration of particles, thereby improving the sedimentation processes essential for purifying industrial effluents.

Authoritative knowledge in the application of industrial flocculants can also prevent potential environmental hazards. Given that incorrect usage can lead to chemical overdosing, which poses risks to aquatic ecosystems and human health, it's critical to employ best practices and adhere to regulatory standards. Institutions that leverage authoritative expertise often draft stringent SOPs (Standard Operating Procedures) ensuring that flocculants are used responsibly and effectively. Trustworthiness of flocculant suppliers is another significant consideration. Partnering with reputable suppliers guarantees not only the quality of the chemicals but also offers access to technical support and expert consultation. Through collaborations with leading suppliers, industries benefit from up-to-date research findings and innovations in flocculant formulations, allowing for enhanced performance and sustainability in operations. Incorporating industrial flocculants into operational protocols yields substantial benefits, such as improved clarity of processed water and reduced sludge production, resulting in lower disposal costs. Ultimately, these factors culminate in a positive impact on the bottom line while safeguarding environmental integrity. As industries continue evolving and facing tighter regulations, the role of industrial flocculants becomes increasingly pivotal. Their utility in achieving compliance, enhancing process efficiency, and fostering sustainable practices cannot be overstated. The insights drawn from experience, coupled with expert guidance and authoritative knowledge, ensure that these chemical agents are employed to their maximum potential, reinforcing trust in their indispensable role within industrial water treatment processes.

Authoritative knowledge in the application of industrial flocculants can also prevent potential environmental hazards. Given that incorrect usage can lead to chemical overdosing, which poses risks to aquatic ecosystems and human health, it's critical to employ best practices and adhere to regulatory standards. Institutions that leverage authoritative expertise often draft stringent SOPs (Standard Operating Procedures) ensuring that flocculants are used responsibly and effectively. Trustworthiness of flocculant suppliers is another significant consideration. Partnering with reputable suppliers guarantees not only the quality of the chemicals but also offers access to technical support and expert consultation. Through collaborations with leading suppliers, industries benefit from up-to-date research findings and innovations in flocculant formulations, allowing for enhanced performance and sustainability in operations. Incorporating industrial flocculants into operational protocols yields substantial benefits, such as improved clarity of processed water and reduced sludge production, resulting in lower disposal costs. Ultimately, these factors culminate in a positive impact on the bottom line while safeguarding environmental integrity. As industries continue evolving and facing tighter regulations, the role of industrial flocculants becomes increasingly pivotal. Their utility in achieving compliance, enhancing process efficiency, and fostering sustainable practices cannot be overstated. The insights drawn from experience, coupled with expert guidance and authoritative knowledge, ensure that these chemical agents are employed to their maximum potential, reinforcing trust in their indispensable role within industrial water treatment processes.

Share

Latest news

-

Water Treatment with Flocculant Water TreatmentNewsJun.12,2025

-

Polymaleic AnhydrideNewsJun.12,2025

-

Polyaspartic AcidNewsJun.12,2025

-

Enhance Industrial Processes with IsothiazolinonesNewsJun.12,2025

-

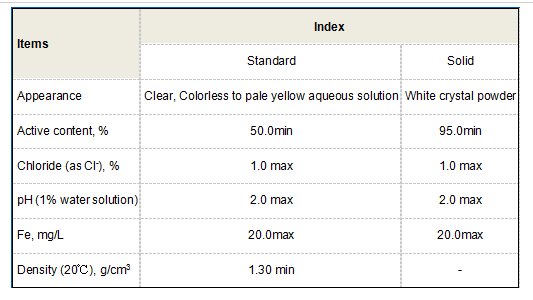

Enhance Industrial Processes with PBTCA SolutionsNewsJun.12,2025

-

Dodecyldimethylbenzylammonium Chloride SolutionsNewsJun.12,2025